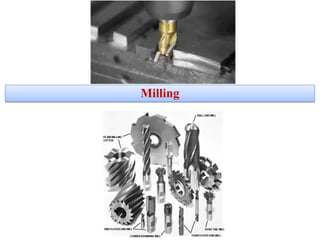

1. The document discusses milling operations and processes. It describes different types of milling machines, cutters, workholding devices, toolholding devices, and machining operations like face milling and peripheral milling.

2. It provides information on milling applications in various industries like aerospace, automotive, medical, and discusses factors involved in calculating machining time.

3. Cutting parameters for milling operations like cutting speed, feed per tooth, axial and radial depths are also outlined.