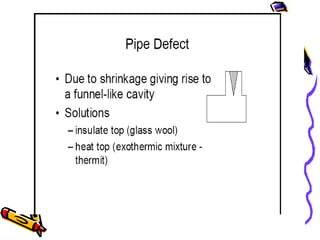

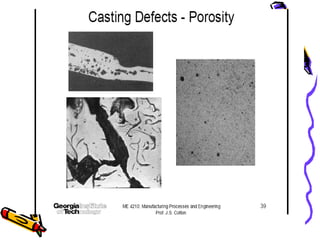

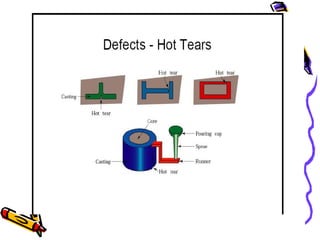

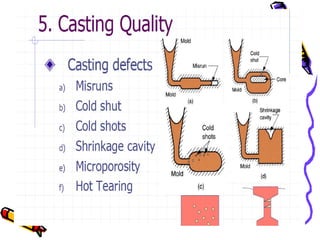

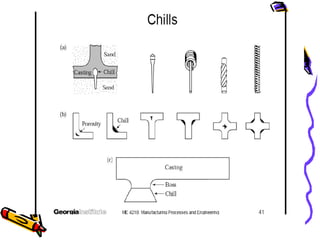

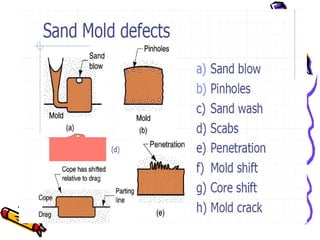

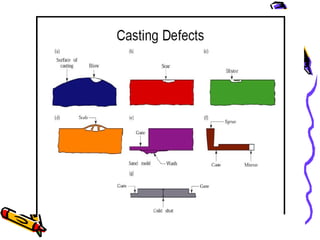

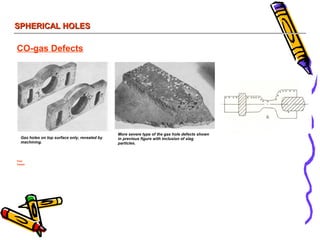

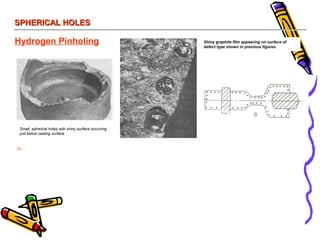

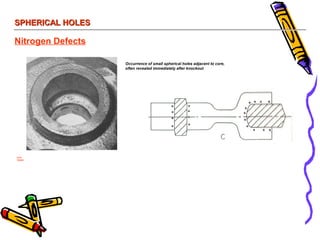

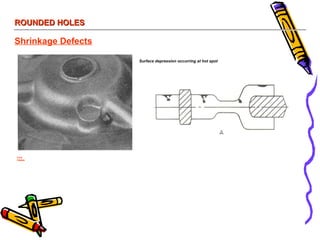

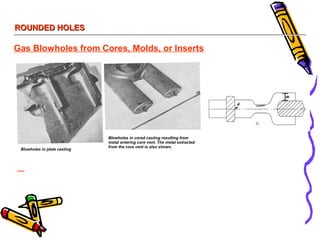

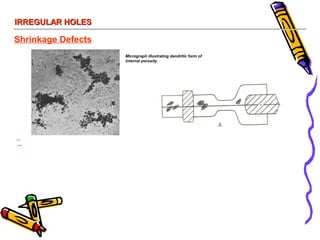

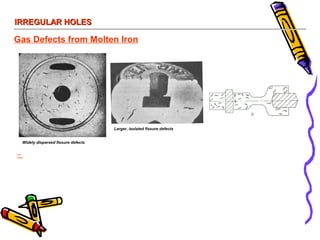

The document discusses various types of casting defects including their forms, causes, and prevention methods. It covers shaping faults from pouring like misruns and cold shuts caused by low metal temperature or moisture in sand. Shrinkage defects from inadequate gating and risering are described. Contraction defects like hot tears occur when thin and thick sections cool at different rates. Gas defects result from entrapped gases or gases evolving during solidification. Inclusions and sand defects enter the melt during pouring. Dimensional errors occur from mold distortions. Compositional errors and segregation vary the alloy composition.