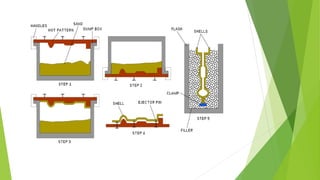

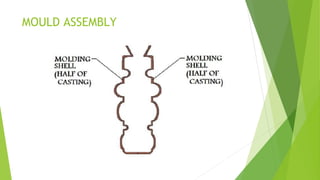

Shell moulding is a casting process that uses a sand-resin mixture to form a disposable mould around a reusable pattern. This allows for higher production rates than sand casting while also enabling more complex part geometries. The process involves creating a metal pattern, heating it, applying a sand-resin mixture to form shell halves, joining the shells to create the mould, pouring molten metal, and removing the casting after solidification. Shell moulding provides better dimensional accuracy, higher productivity, and lower labor costs than sand casting for small to medium precision parts.