The document discusses capsule dosage forms. Some key points include:

1. Capsules can be used to mask unpleasant drug tastes, smells, or appearances. They also allow powders to be dispensed uncompressed, aiding faster drug dissolution and absorption compared to tablets.

2. Capsules offer versatility in preparing varied drug doses and administration routes like oral, inhalation, and others. They can also be easier than tablets for some patients to swallow.

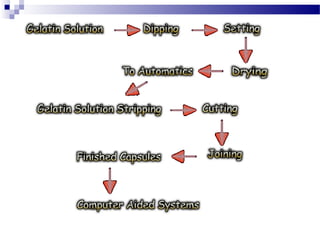

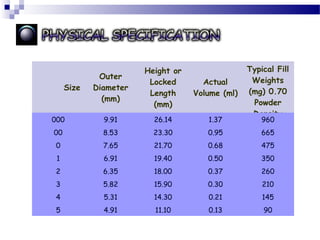

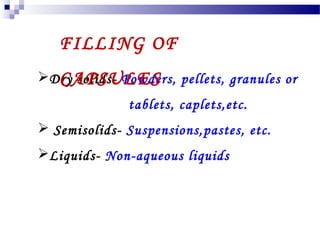

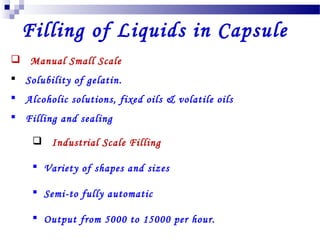

3. Capsule production involves filling empty shells with powders, granules, beads, pastes, liquids or other formulations. Both manual and automated high-output filling machines exist. Quality control ensures proper capsule appearance, weight, content uniform

![Capsule Filling, Problems in Filling & Remedies

Filling capsule with a

semisolid mass.

Forming a pipe or pouring a melt.

Pipe:

Consistency is important.

[For fluid- cornstarch or similar material for firm

cosistancy.]

Semisolid melt:

For too firm with satisfactory M.P. materials.

For enhancing the bioavailability of poorly soluble drugs.

[Drug + melt of materials like PEG]](https://image.slidesharecdn.com/capsules-101127083830-phpapp02/85/Capsules-13-320.jpg)

![DIFFICULTIES IN CAPSULE FILLING

1. Deliquescent / Hygroscopic powders.

Remedy: Adsorbent [magnesium carbonate, heavy / light

magnesium oxide]

2. Eutectic mixture

Remedy: Use of adsorbent [magnesium carbonate, kaolin]

3. Small dose of drug

Remedy: Addition of inert powder.

4. Incompatibilities of materials

Remedy: Use of two capsules – small in large

5. Lack of adhessiveness difficult to fill by punch method

Remedy: moistened with alcohol , granules reduced to powders](https://image.slidesharecdn.com/capsules-101127083830-phpapp02/85/Capsules-16-320.jpg)

![Capsule Processing

Empty Capsule

Filling [Formulation]

Finishing

# Dusting [Cloth Dusting]

# Polishing [Pan Polishing]

# Brushing

Inspection

Bottling

Labeling](https://image.slidesharecdn.com/capsules-101127083830-phpapp02/85/Capsules-18-320.jpg)

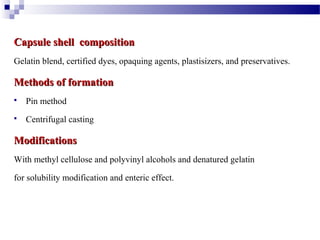

![Special Techniques of Processing

Imprinting

Special purpose Capsules

[To retard solubility of gelatin to delay absorption of drug]

* Formalin treatment

* Various coatings

Separation of Incompatible materials](https://image.slidesharecdn.com/capsules-101127083830-phpapp02/85/Capsules-19-320.jpg)

![In-process Quality And

Quality Control Parameters

Choice of suitable control procedure for filling operation:

[should desirable to provide 100% weight checking after filling]

Capsule Appearance

Weight veriation

Content uniformity

Solubility

Disintegration test](https://image.slidesharecdn.com/capsules-101127083830-phpapp02/85/Capsules-23-320.jpg)