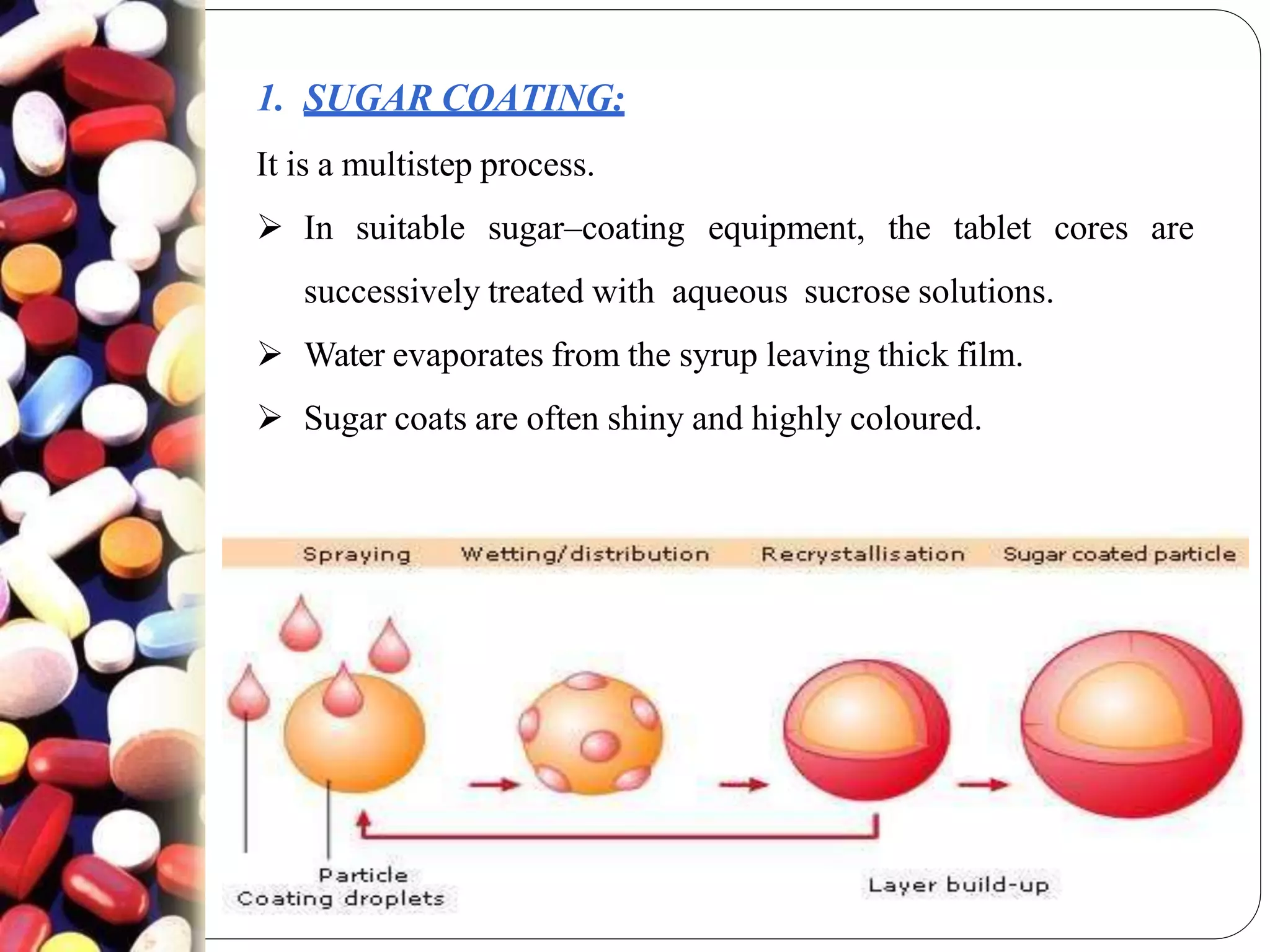

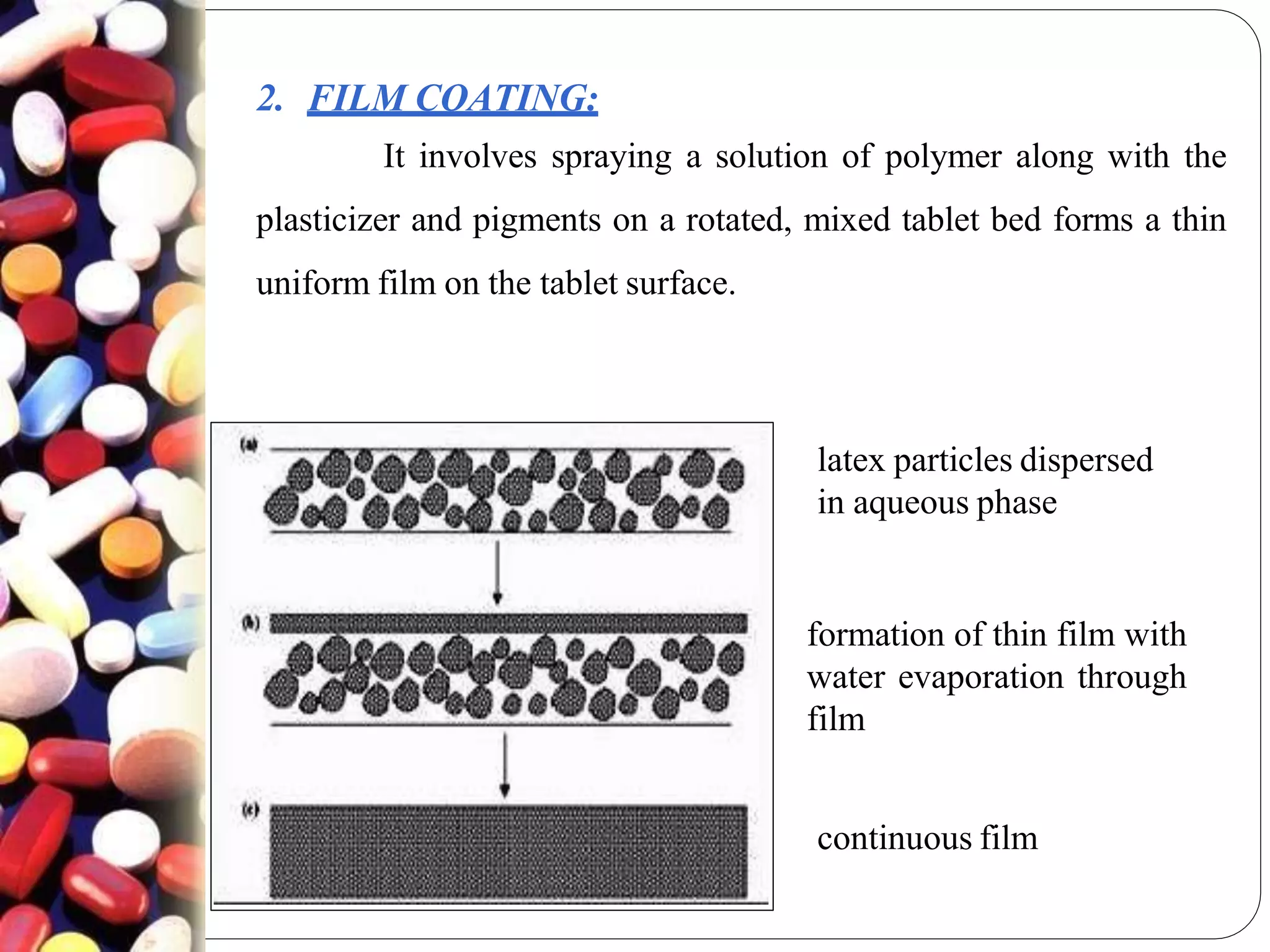

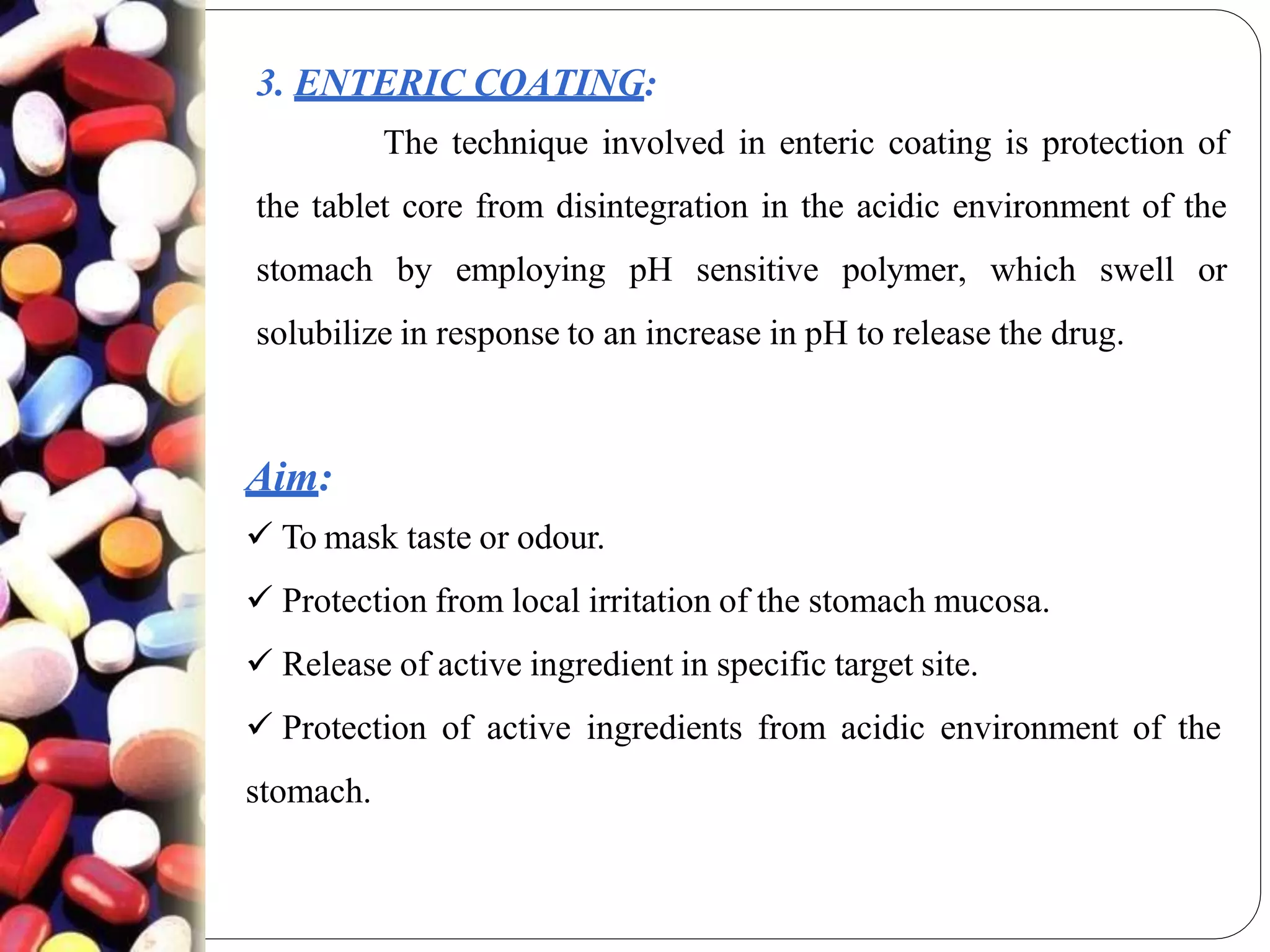

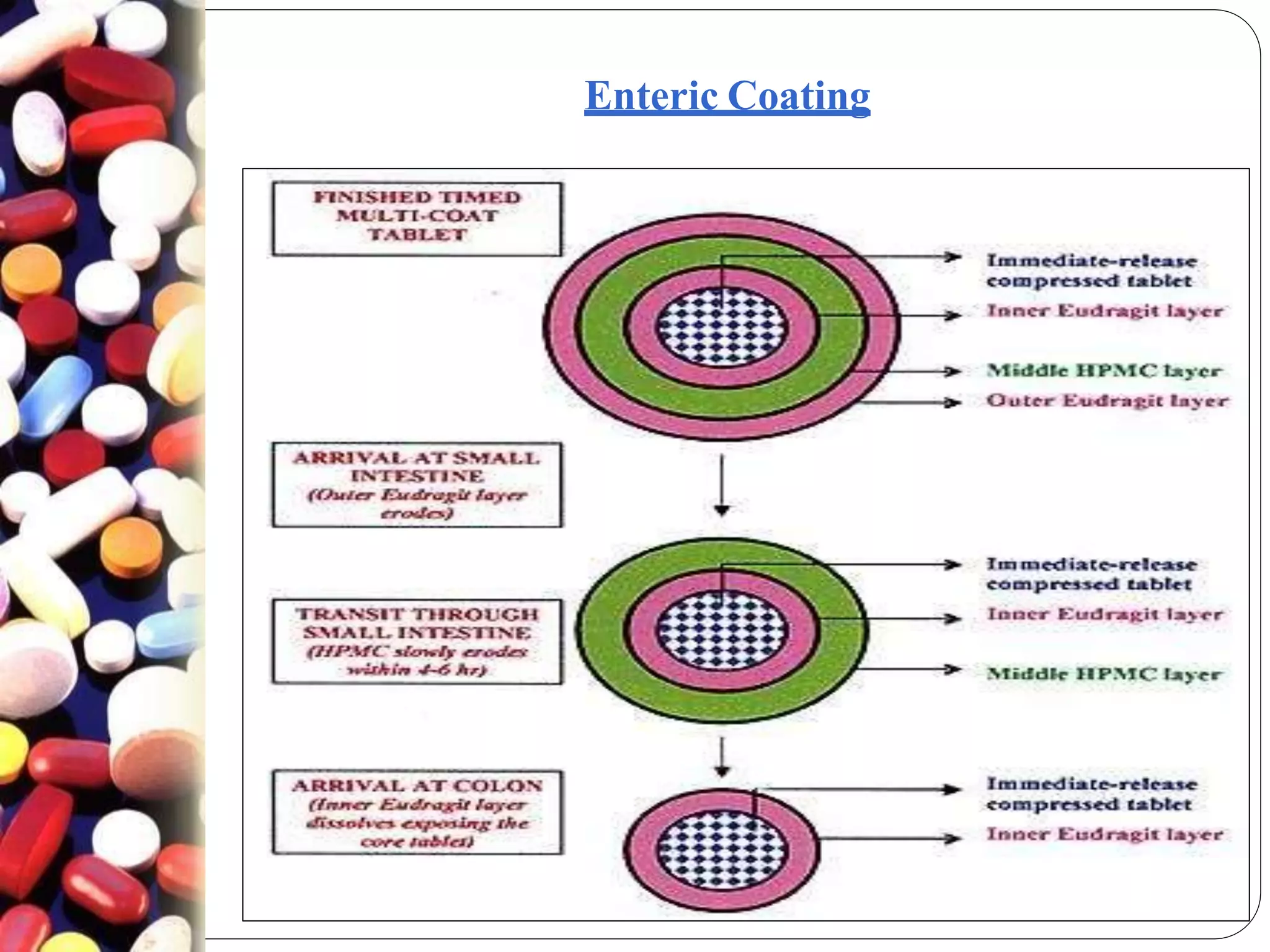

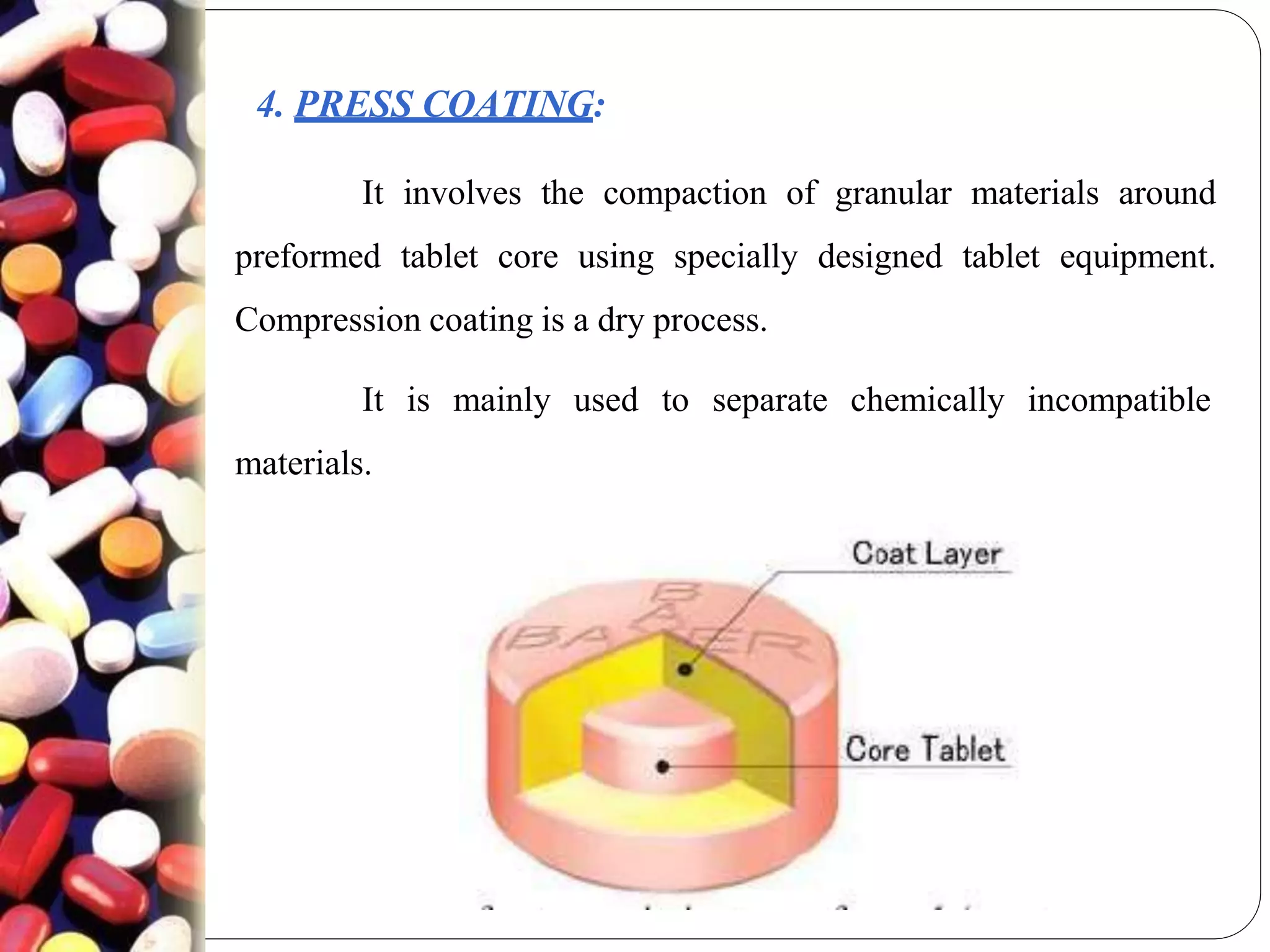

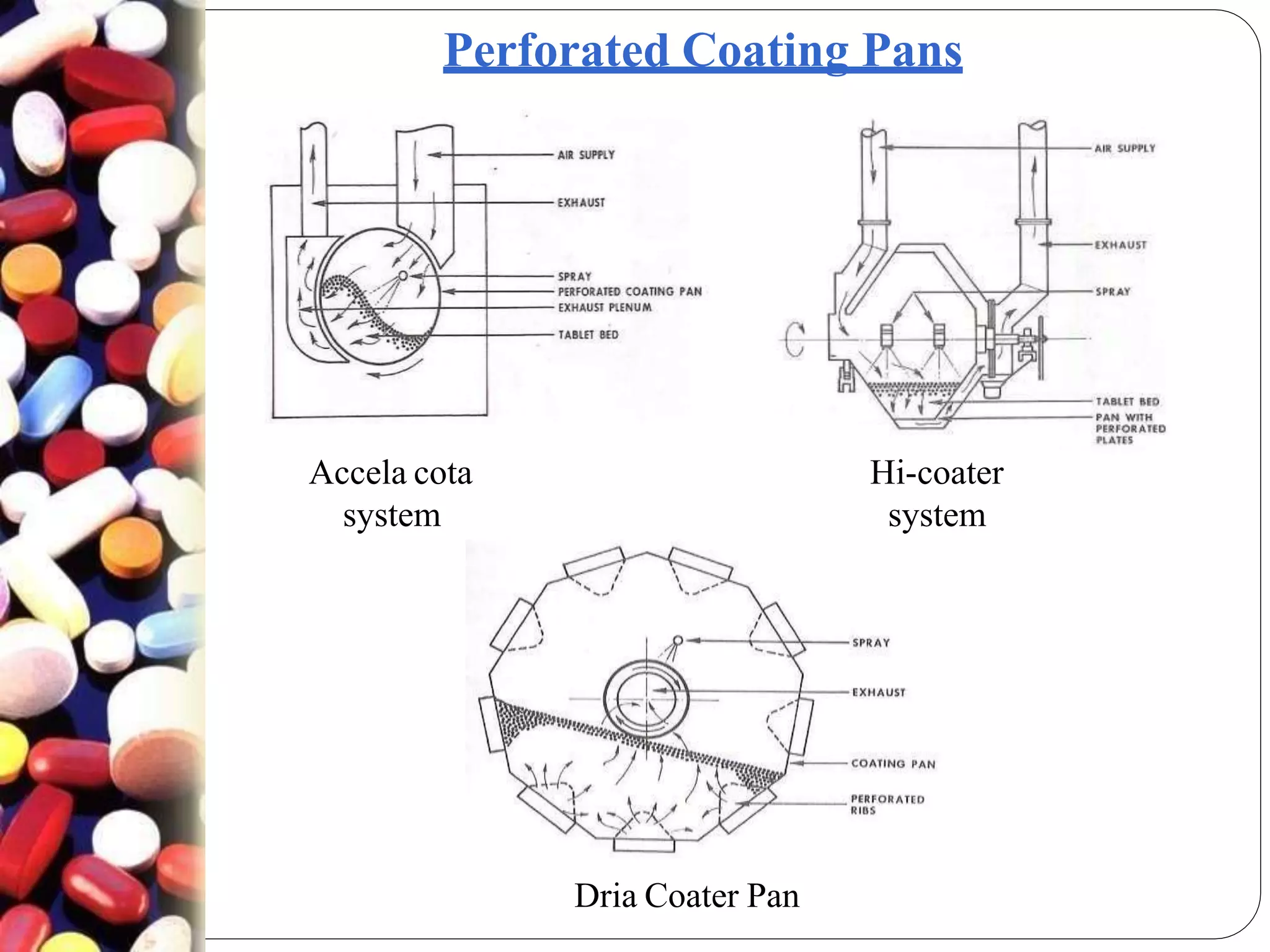

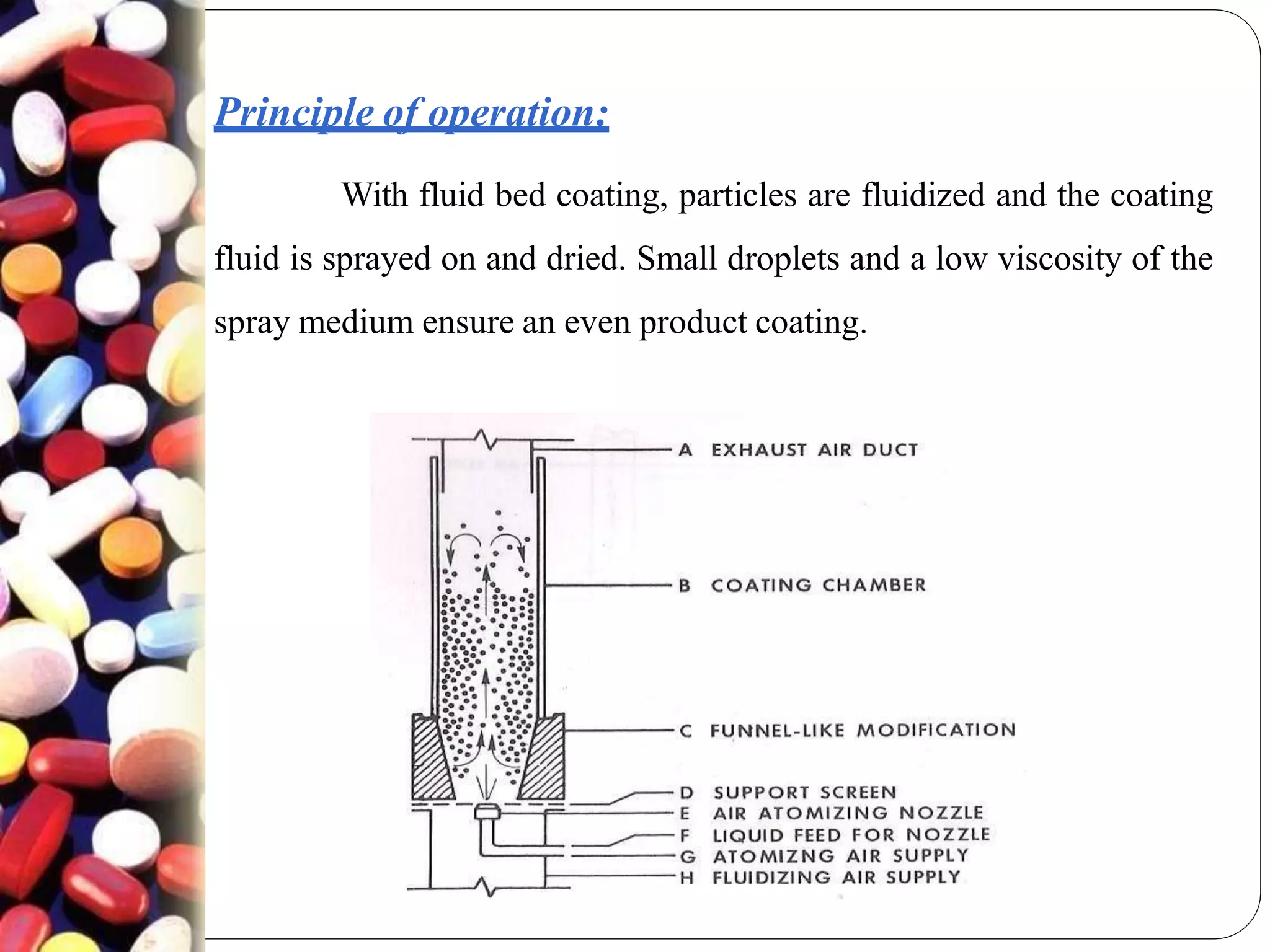

The document provides a comprehensive overview of tablet coating, detailing its definition, principles, advantages, disadvantages, types, equipment used, defects, and applications. Key coating methods discussed include sugar coating, film coating, enteric coating, and press coating, along with their processes and characteristics. It emphasizes the importance of coating for drug stability, patient compliance, and improved aesthetic appeal, while also addressing challenges such as costs and technical expertise.