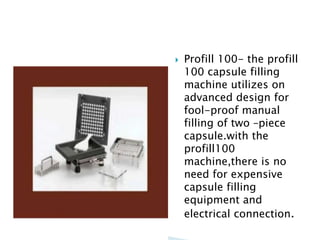

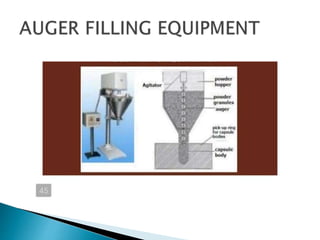

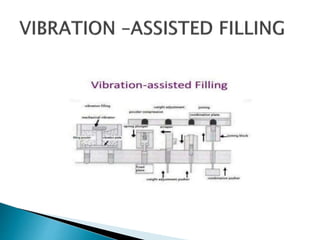

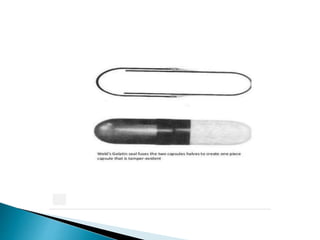

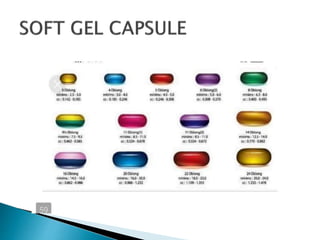

The document discusses capsule filling machines and the capsule filling process. It describes the Profill 100 capsule filling machine which uses manual filling and does not require expensive equipment. It then explains different filling principles like vibratory filling and dosing disc/dosator principles. The document also covers capsule sealing methods, quality control steps, and types of capsule filling machines. It provides information on soft gelatin capsules, including formulation, manufacturing methods like the plate process, and advantages over hard capsules.