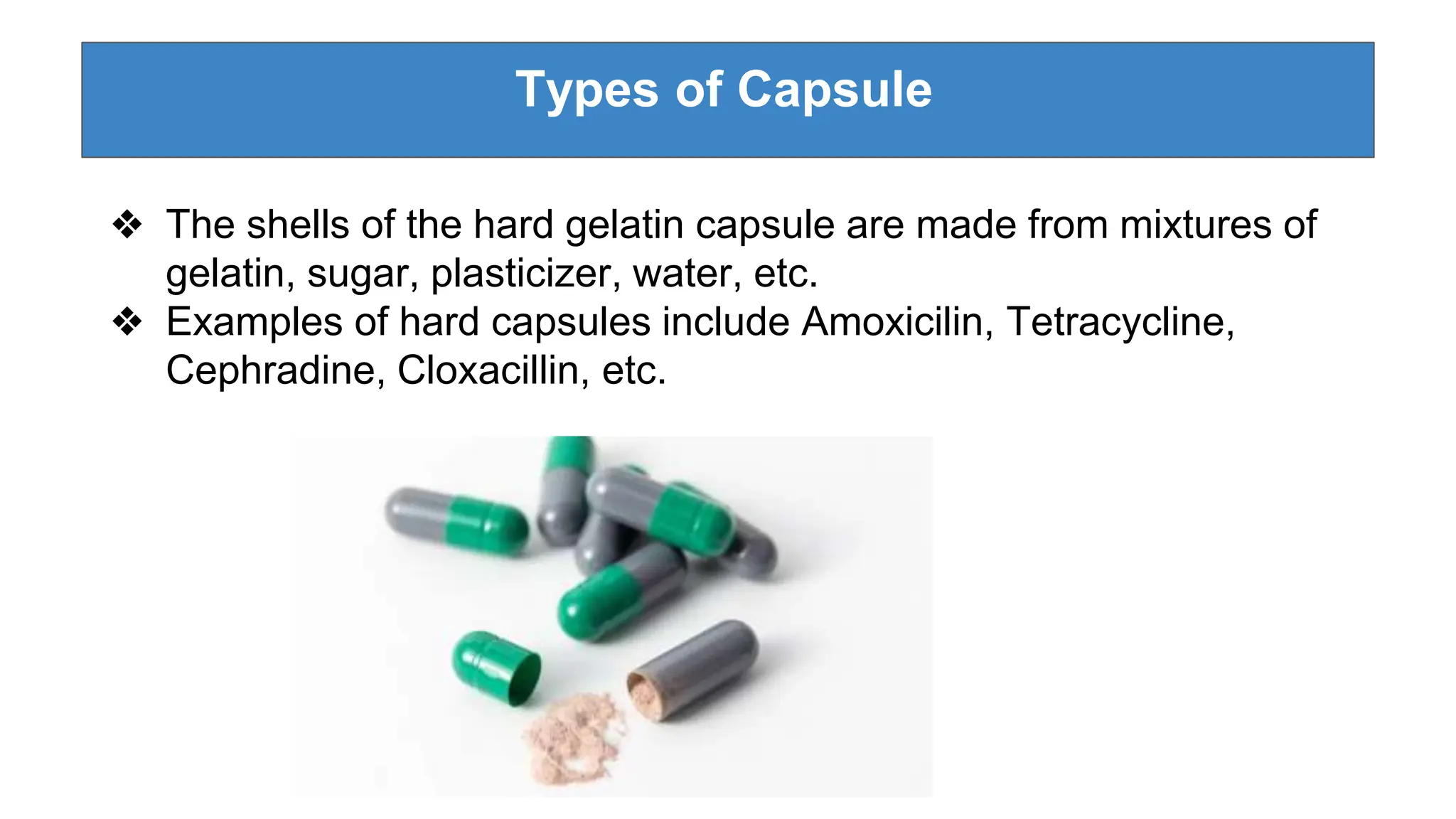

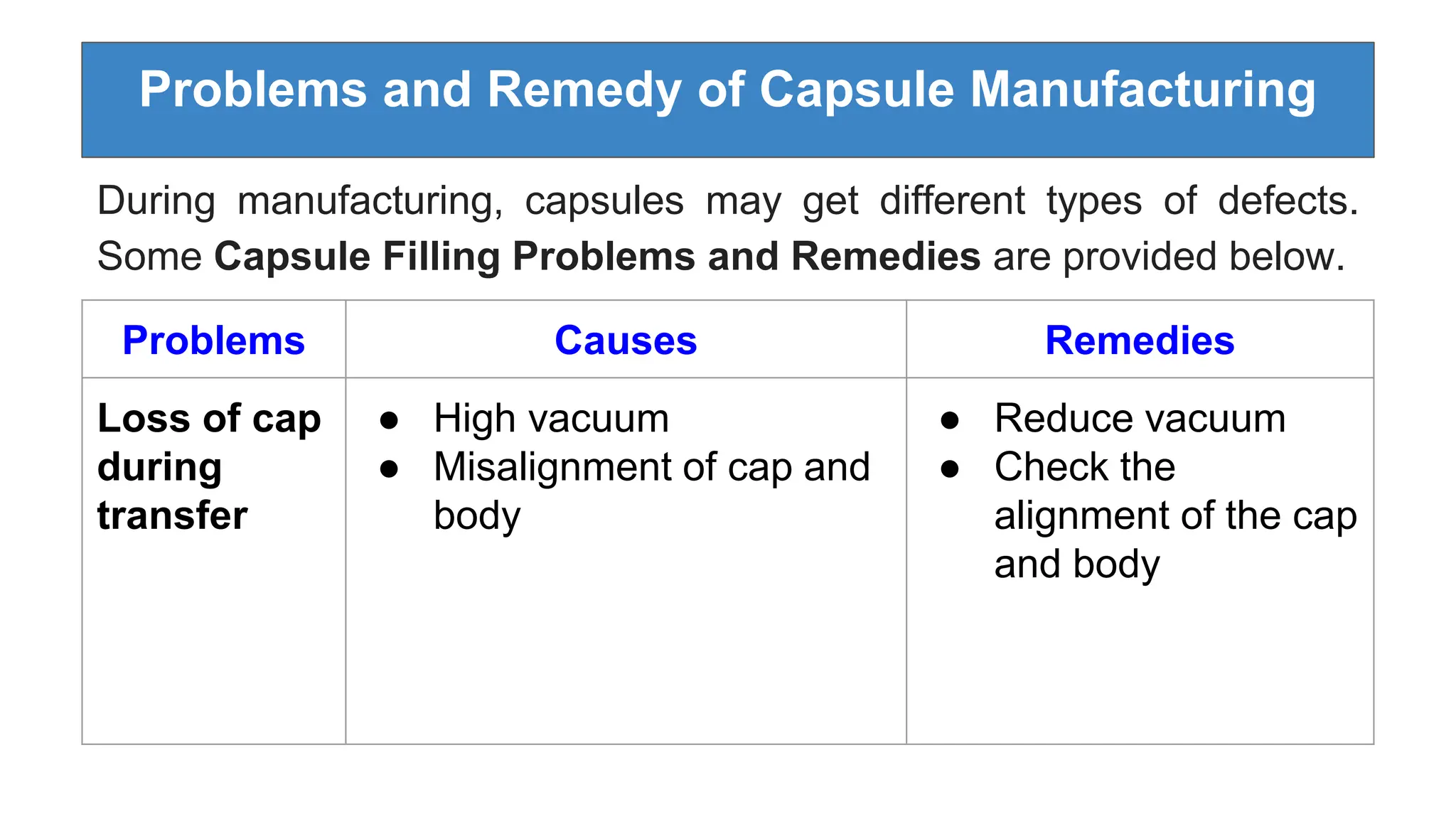

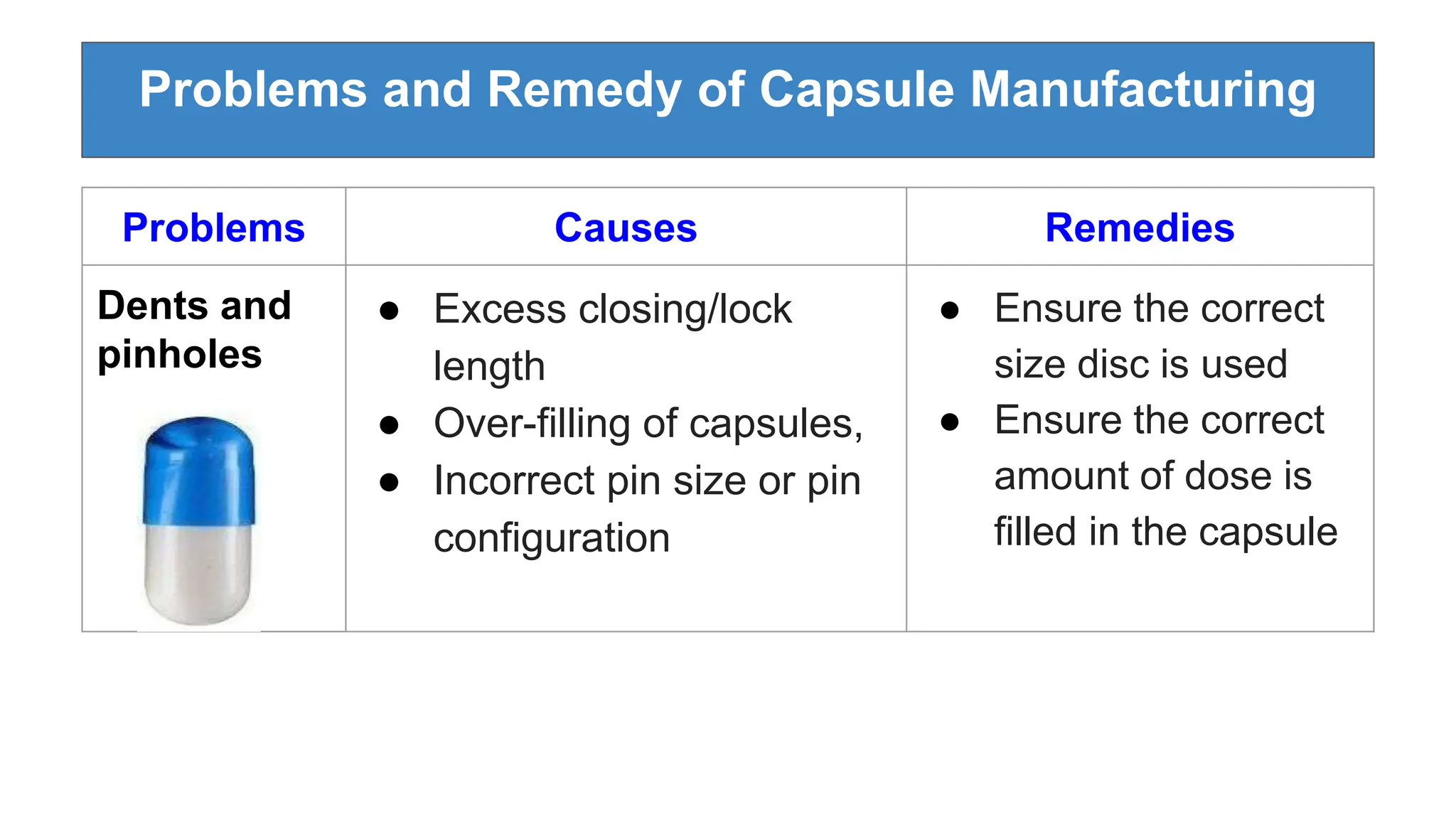

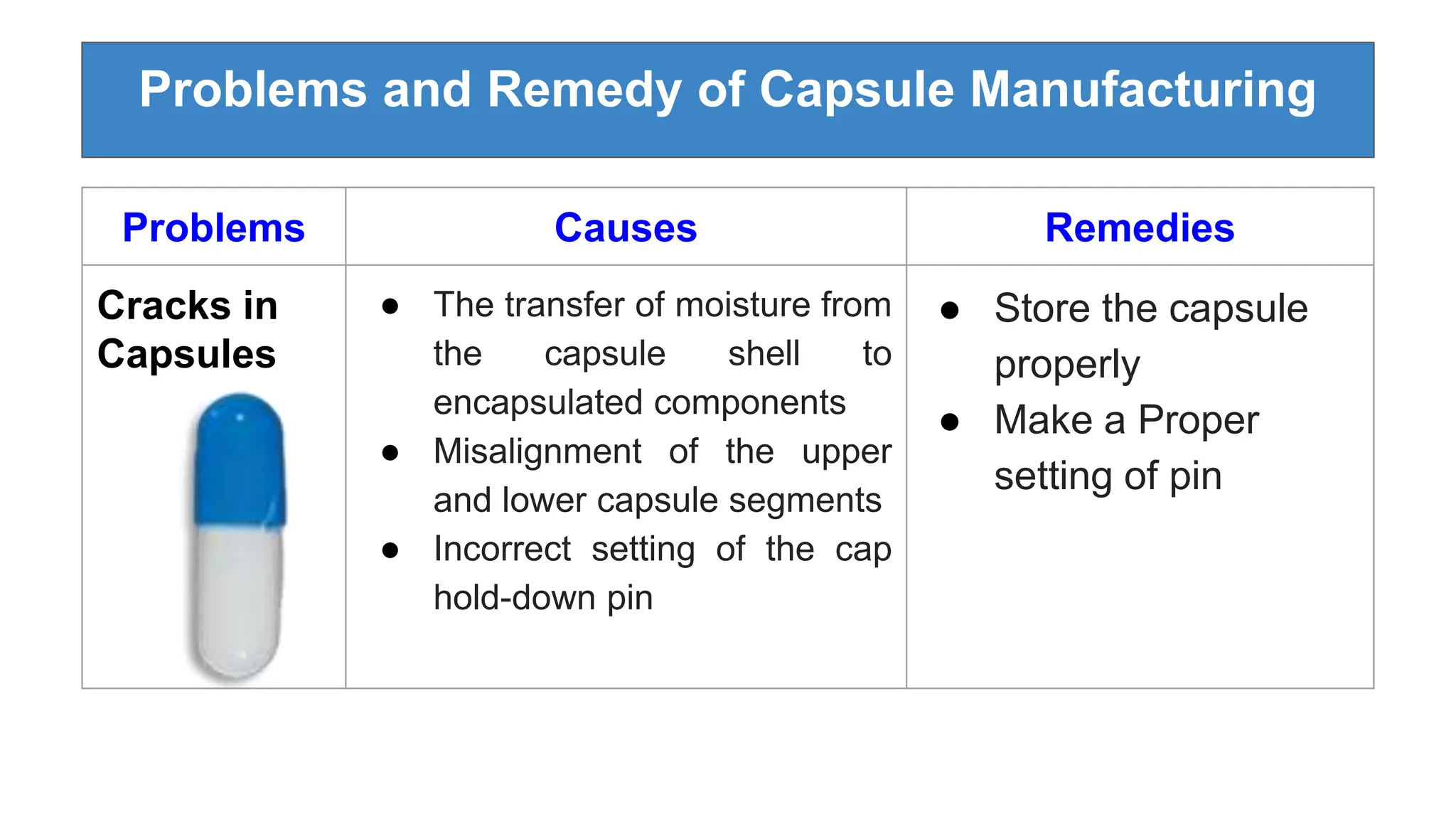

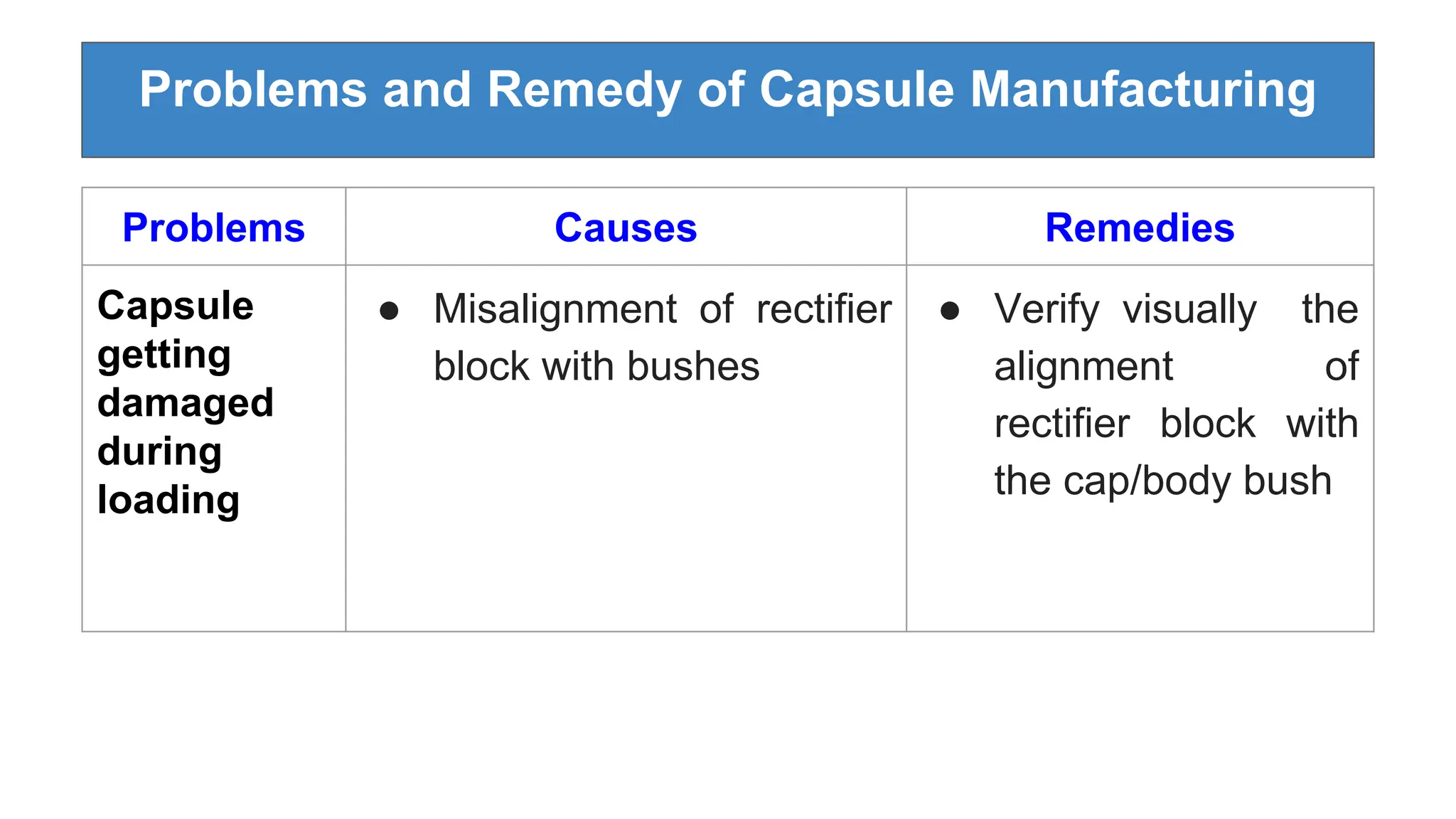

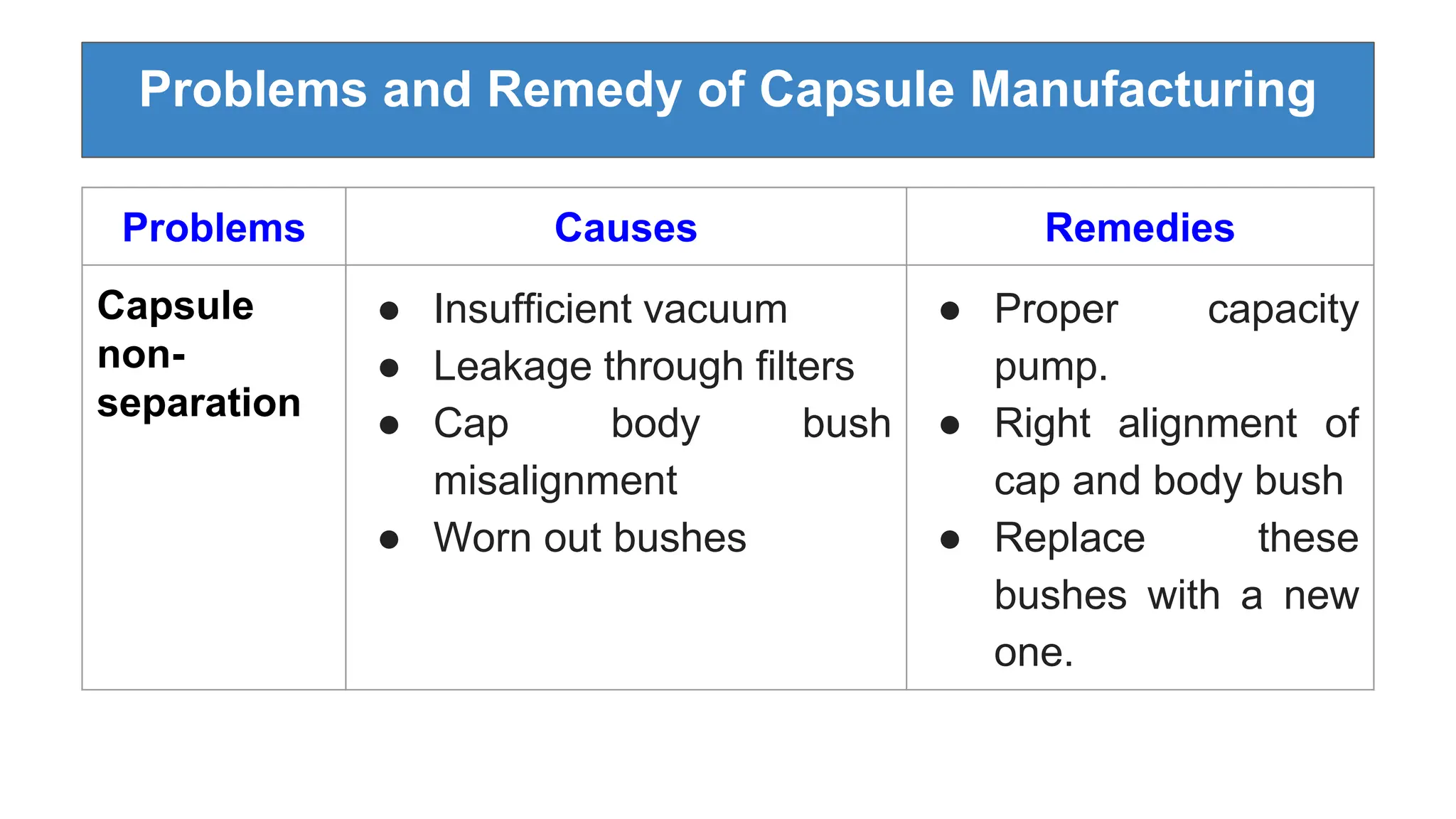

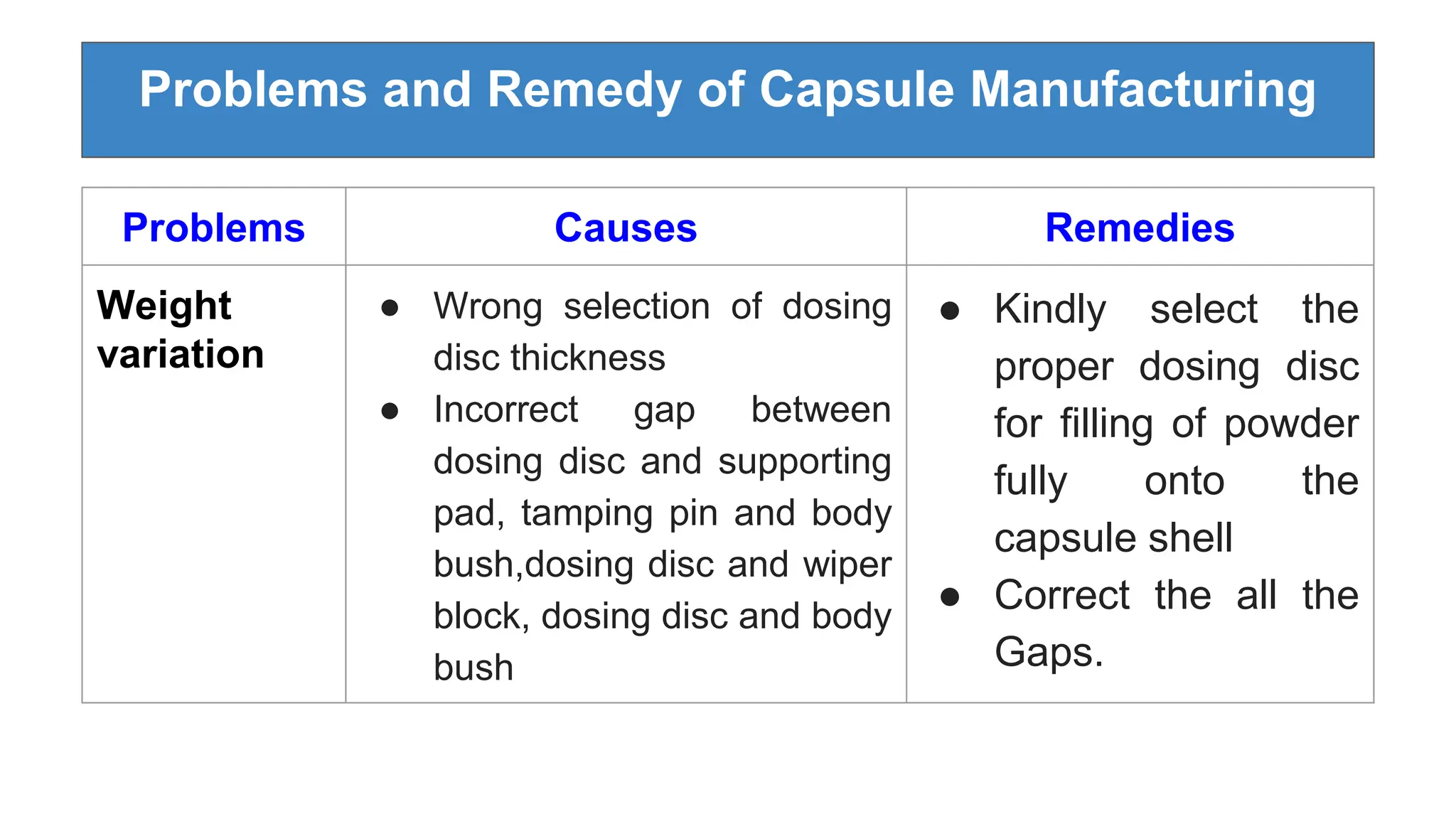

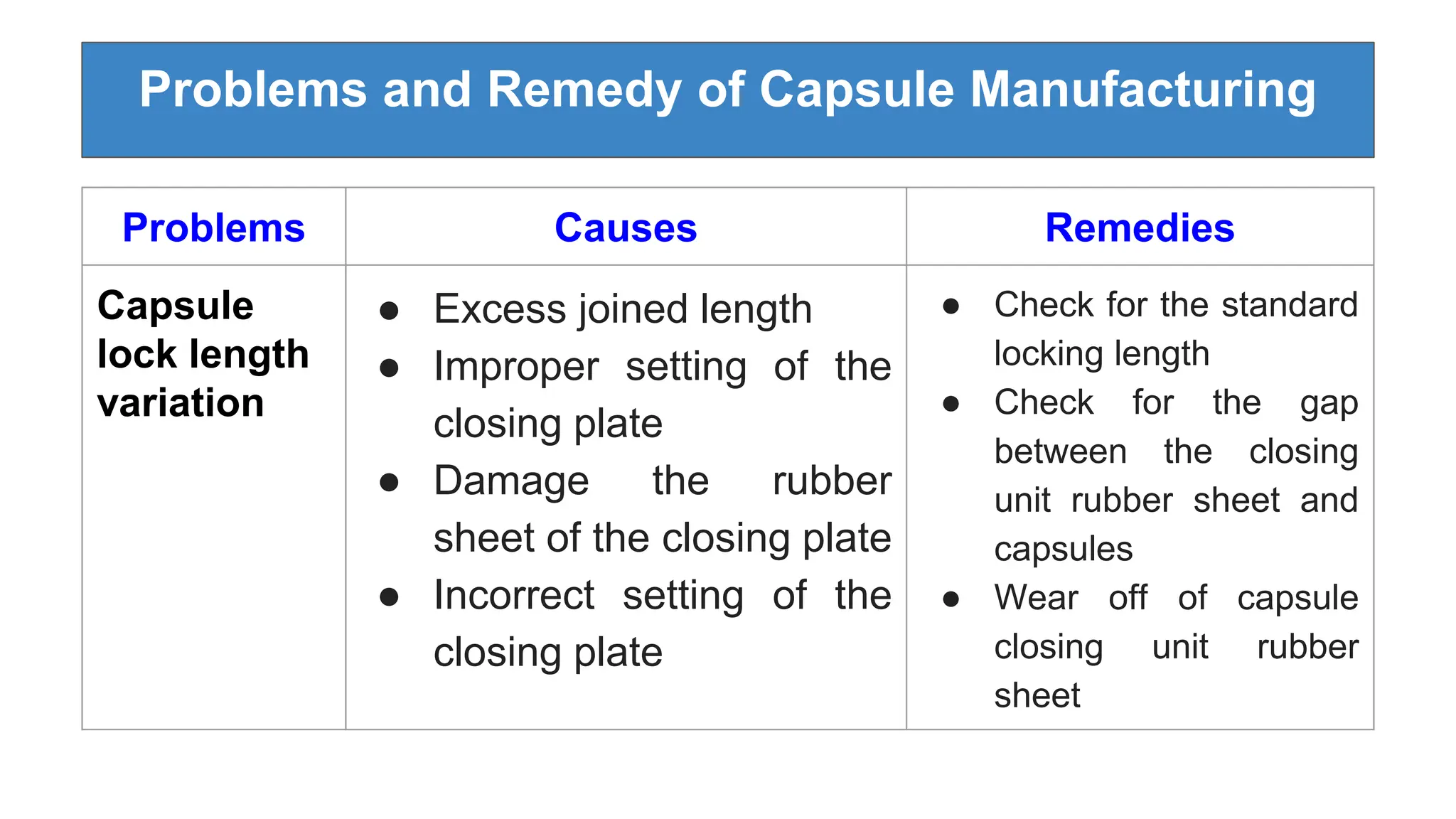

This presentation discusses capsule manufacturing and common problems. There are two main types of capsules - hard gelatin capsules and soft gelatin capsules. Hard capsules have two shells while soft capsules have a one-piece shell. Common problems in manufacturing include loss of caps, dents, cracks, telescoping, dust, empties, and more. These problems are caused by issues like high vacuum levels, misalignment, overfilling, incorrect pin sizes, and moisture transfer. Solutions include reducing vacuum, ensuring proper alignment, using the correct fill amounts and disc sizes, storing capsules properly, and replacing worn equipment.