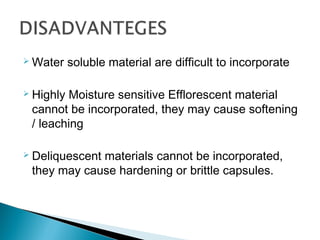

This document defines soft gelatin capsules and describes their anatomy, manufacturing process, quality considerations, and types. Soft gelatin capsules have a soft gelatin shell containing liquids, suspensions, or semisolids. The shell is made of gelatin, plasticizer, and water. The content can be liquids, solutions, or suspensions. The manufacturing process involves making the gel and content mixtures, encapsulating using machinery, drying, inspecting, and packaging. Quality is ensured through ingredient and in-process testing and finished product testing. Vegicaps are an alternative animal-free soft capsule with a seaweed and starch shell.

![Mr. Nitin M. KadamMr. Nitin M. Kadam

M.Pharm [Pharmaceutics],

nitkadam@gmail.com](https://image.slidesharecdn.com/lectureonsoftgelatincapsules-101127084110-phpapp01/85/Soft-Gelatin-Capsules-1-320.jpg)