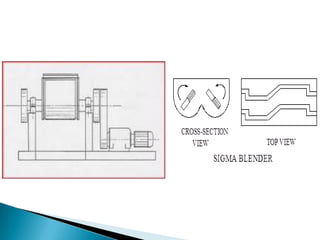

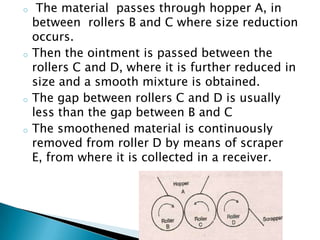

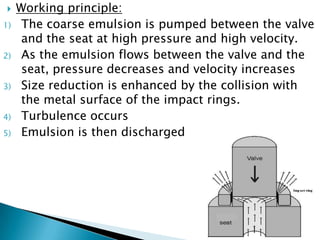

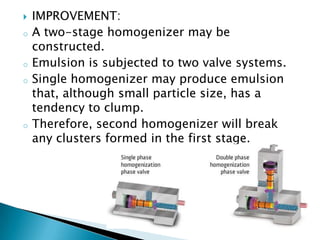

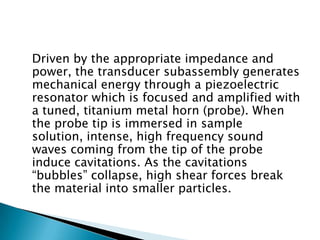

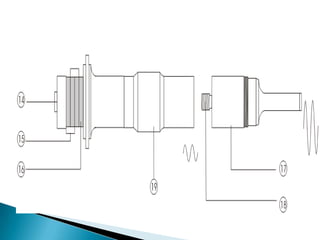

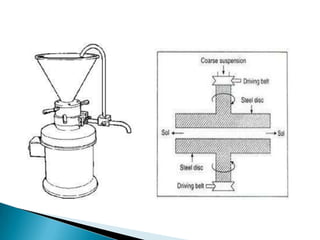

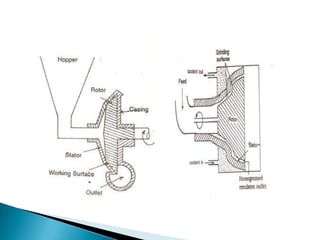

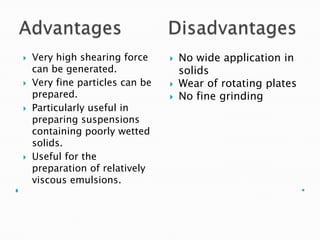

The document discusses the concept of mixing as a critical operation in pharmaceutical and related industries, explaining different types of mixtures (positive, negative, neutral) and their properties. It highlights various mixing equipment such as planetary mixers, sigma blade mixers, and homogenizers, detailing their construction, working principles, and applications. The document also covers the importance of parameters like agitation, temperature control, and machinery specifications in achieving effective mixing outcomes.