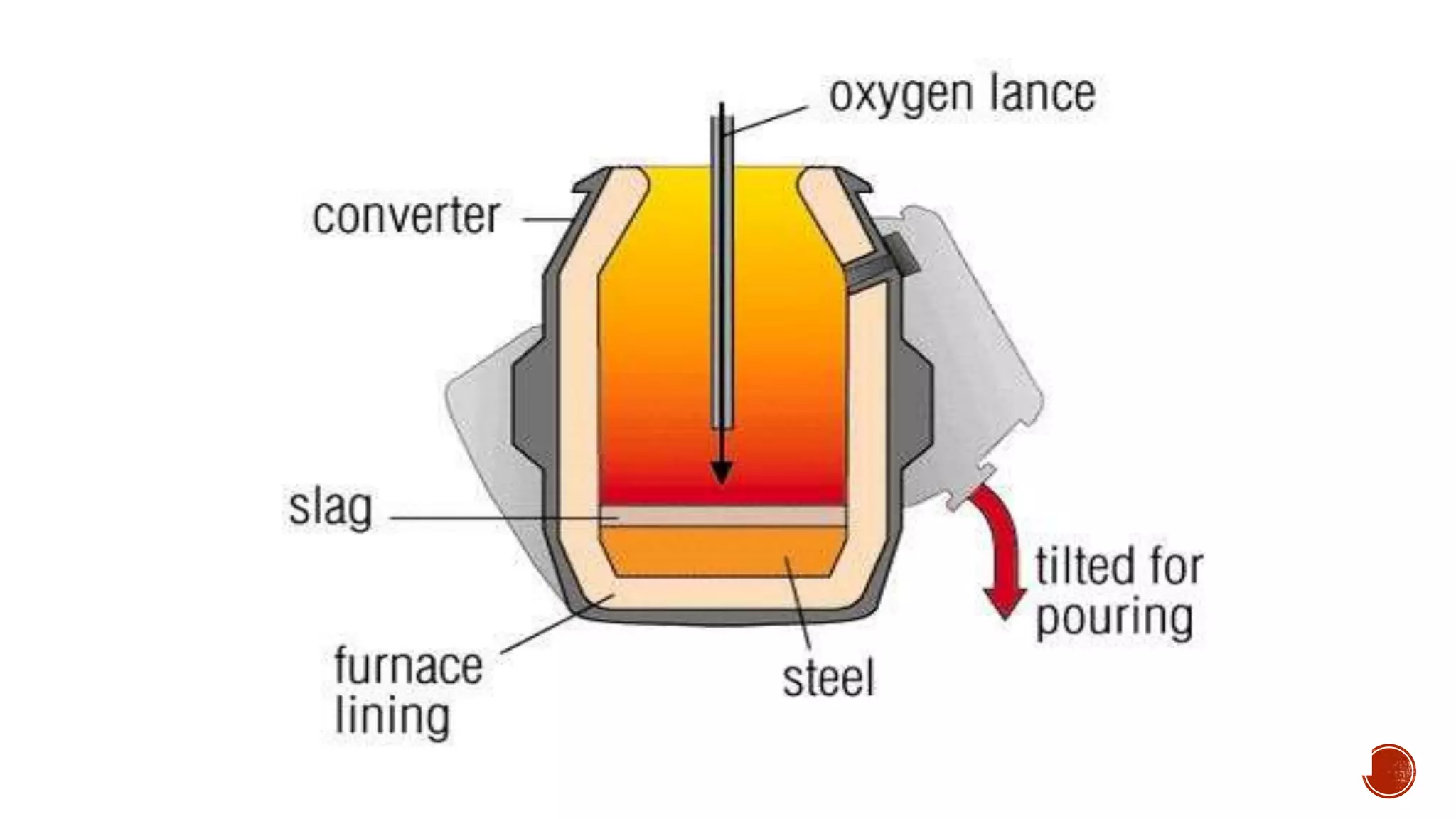

The document summarizes the basic oxygen furnace process. Molten pig iron and scrap are refined in a basic oxygen furnace by injecting high-purity oxygen. This reduces the carbon content and removes impurities. About 67% of the world's crude steel is produced using this process. Key aspects of the basic oxygen furnace include injection of oxygen through a lance to react with carbon and impurities, formation of slag to absorb impurities, and tapping of refined steel once processing is complete.

![ The basic oxygen furnace uses no additional fuel. The pig iron impurities

(carbon, silicon, manganese and phosphorous) serve as fuel. Iron and its impurities

oxidize evolving heat necessary for the process.

Oxidation of the molten metal and the slag is complicated process proceeding in

several stages and occurring simultaneously on the boundaries between

different phases (gas-metal, gas-slag, slag-metal). Finally the reactions may be

presented as follows:

(square brackets [ ] - signify solution in steel, round brackets ( ) - in slag, curly

brackets {} - in gas).](https://image.slidesharecdn.com/bos-131127011227-phpapp02/75/Bos-9-2048.jpg)

![ 1/2{O2} = [O]

[Fe] + 1/2{O2} = (FeO)

[Si] + {O2} = (SiO2)

[Mn] + 1/2{O2} = (MnO)

2[P] + 5/2{O2} = (P2O5)

[C] + 1/2{O2} = {CO}

{CO} + 1/2{O2} = {CO2}

Most oxides are absorbed by the slag.](https://image.slidesharecdn.com/bos-131127011227-phpapp02/75/Bos-10-2048.jpg)