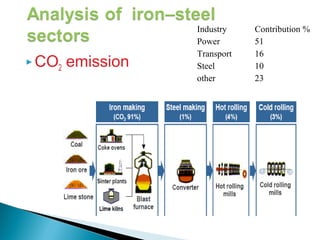

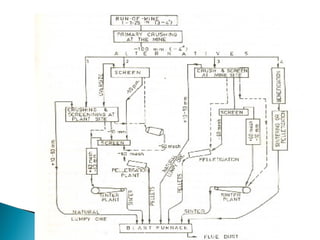

The document discusses key aspects of blast furnace design and operation, including:

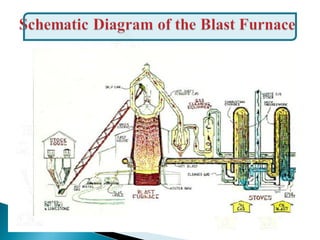

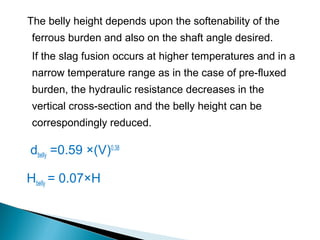

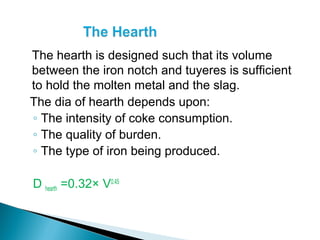

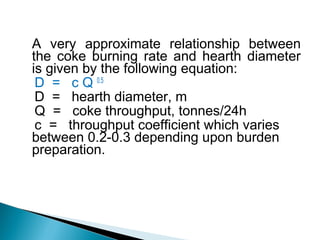

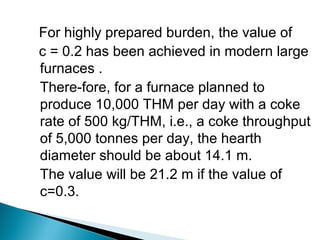

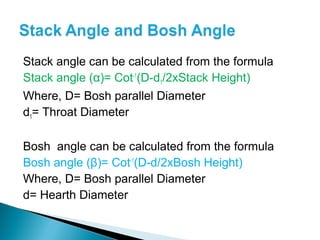

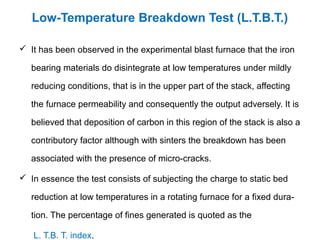

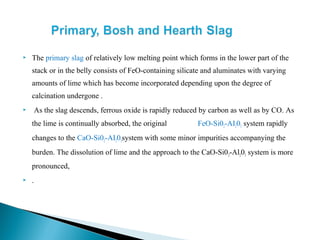

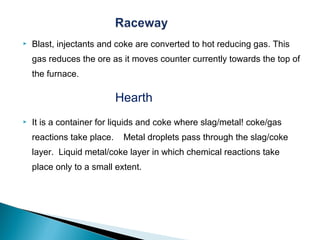

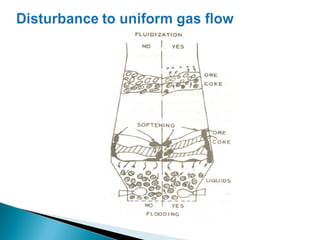

1. Blast furnace productivity depends on optimal gas flow and smooth, rapid burden descent which requires an optimized furnace profile and lines.

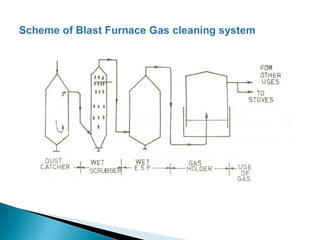

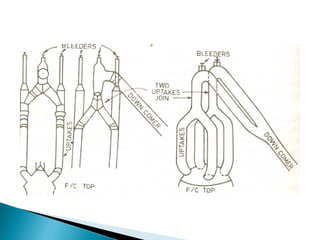

2. Effluent gas from the furnace contains 20-30% CO by volume and is cleaned through three stages before use to reduce dust from 7-30 g/m3 to 0.01 g/m3.

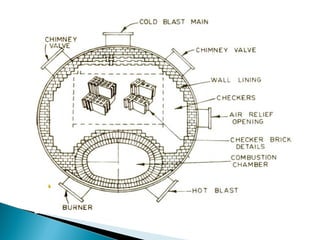

3. Stoves are used to heat incoming blast with heat from cleaned furnace gas in a cyclic process, maintaining a steady, preheated blast supply to the furnace.

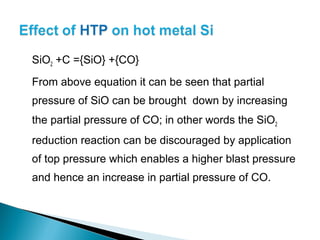

![

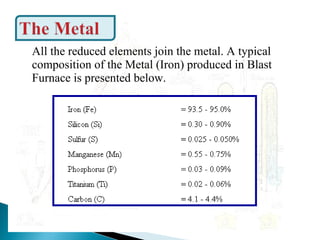

Further down the furnace, impure liquid iron and liquid slag are

formed. The absorption of carbon lowers the melting point of iron

drastically. For example, an iron alloy containing 4 wt. % carbon

melts at only 1185°C..

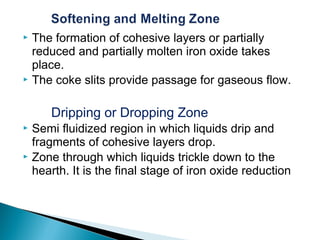

In the cohesive zone and below it, coke is the source of carbon for

carburisation of liquid iron. However, carbon directly does not

dissolve in liquid iron at this stage. The possible mechanism of

carburisation of iron entails the formation of CO by gasification of

carbon, followed by the absorption of carbon by the reaction:

2CO(g) = [C]in Fe+ CO2(g)](https://image.slidesharecdn.com/ironmaking-130302105459-phpapp02/85/Iron-making-159-320.jpg)

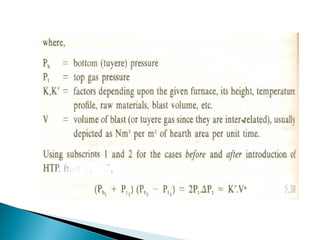

![ Desulphurisation of metal droplets through slag-

metal reaction in the furnace hearth :

(CaO) + [S] + [C ]= (CaS) + CO (g)

Desulphurisation through the coupled reaction:

(CaO) +[S] +[ Mn] = (CaS) + (MnO)

(CaO) + [S] + ½[ Si] = (CaS) + 1/2 (SiO2)](https://image.slidesharecdn.com/ironmaking-130302105459-phpapp02/85/Iron-making-197-320.jpg)

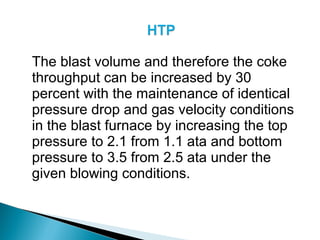

![ Sulphur pick-up through the vapour-

phase reaction:

CaS( in coke ash) + SiO (g) = SiS(g) +

CaO

FeS( in coke ash) + SiO (g) = SiS(g) +

CO(g) +[Fe]

In the bosh and belly regions, SiS

decomposes as

SiS(g) = [Si] + [S]](https://image.slidesharecdn.com/ironmaking-130302105459-phpapp02/85/Iron-making-198-320.jpg)