The document summarizes the key steps in the oxygen top blowing steelmaking process. It describes:

1) The raw materials charged including hot metal, scrap, and fluxes that are used to form slag.

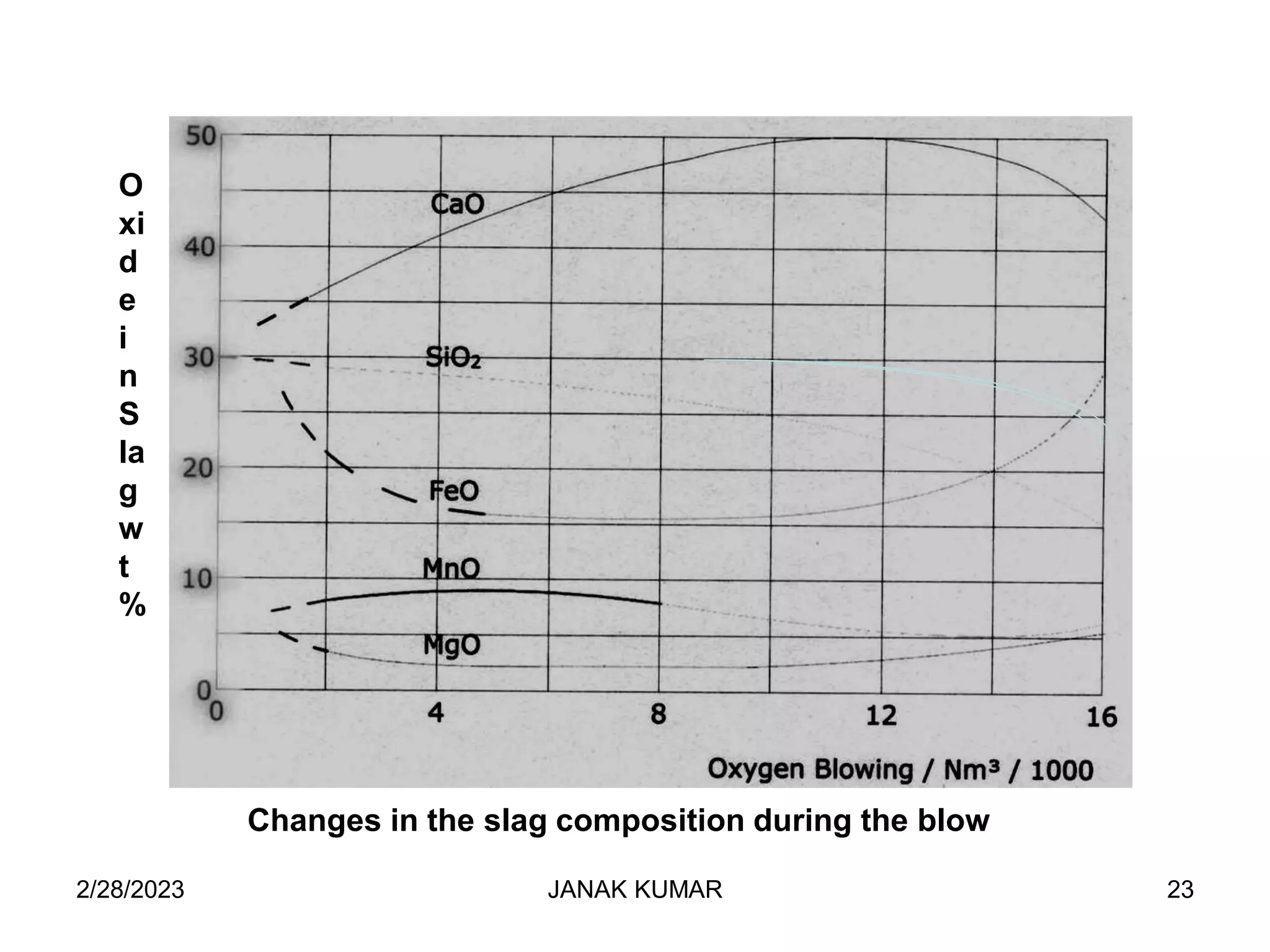

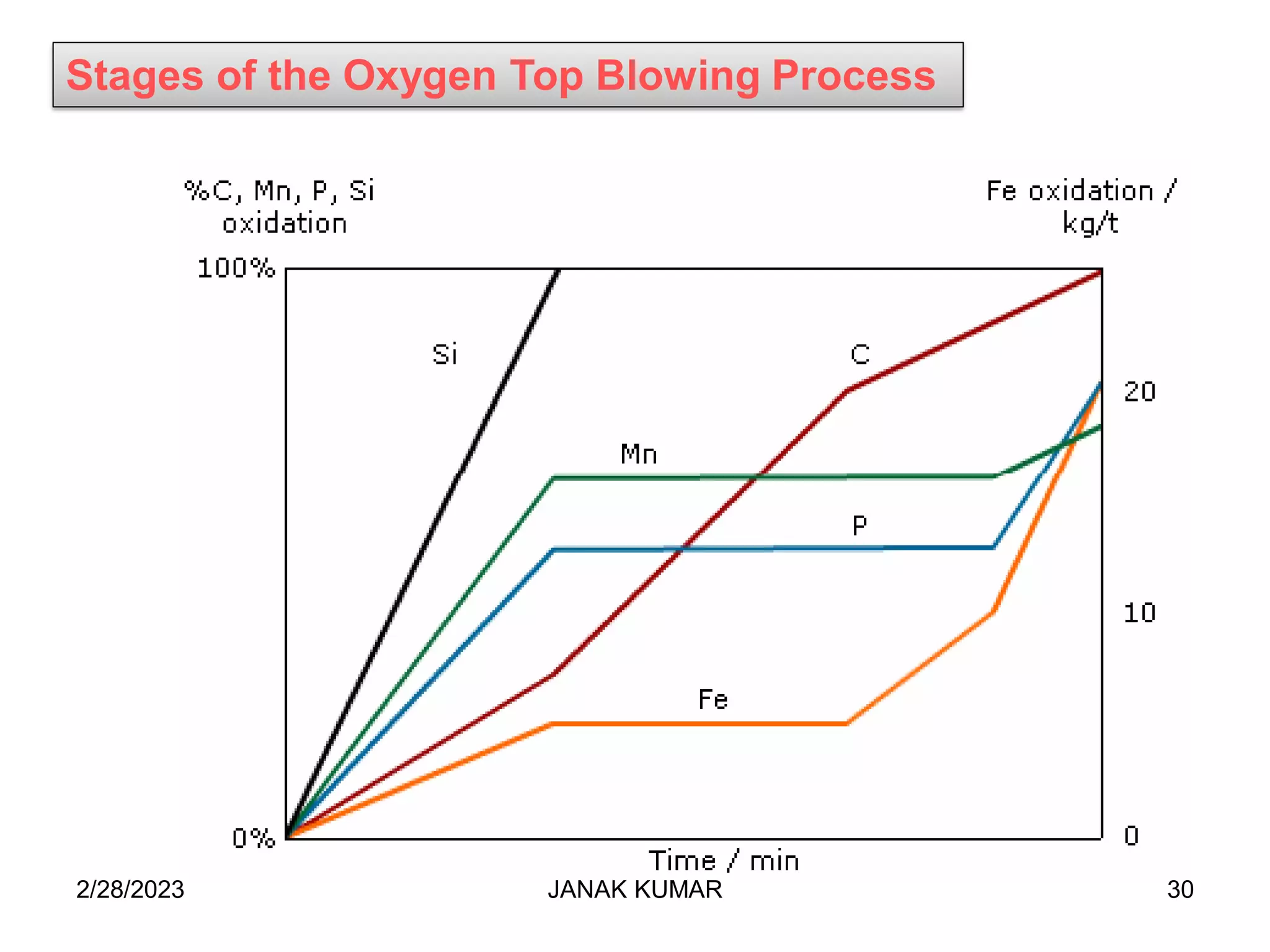

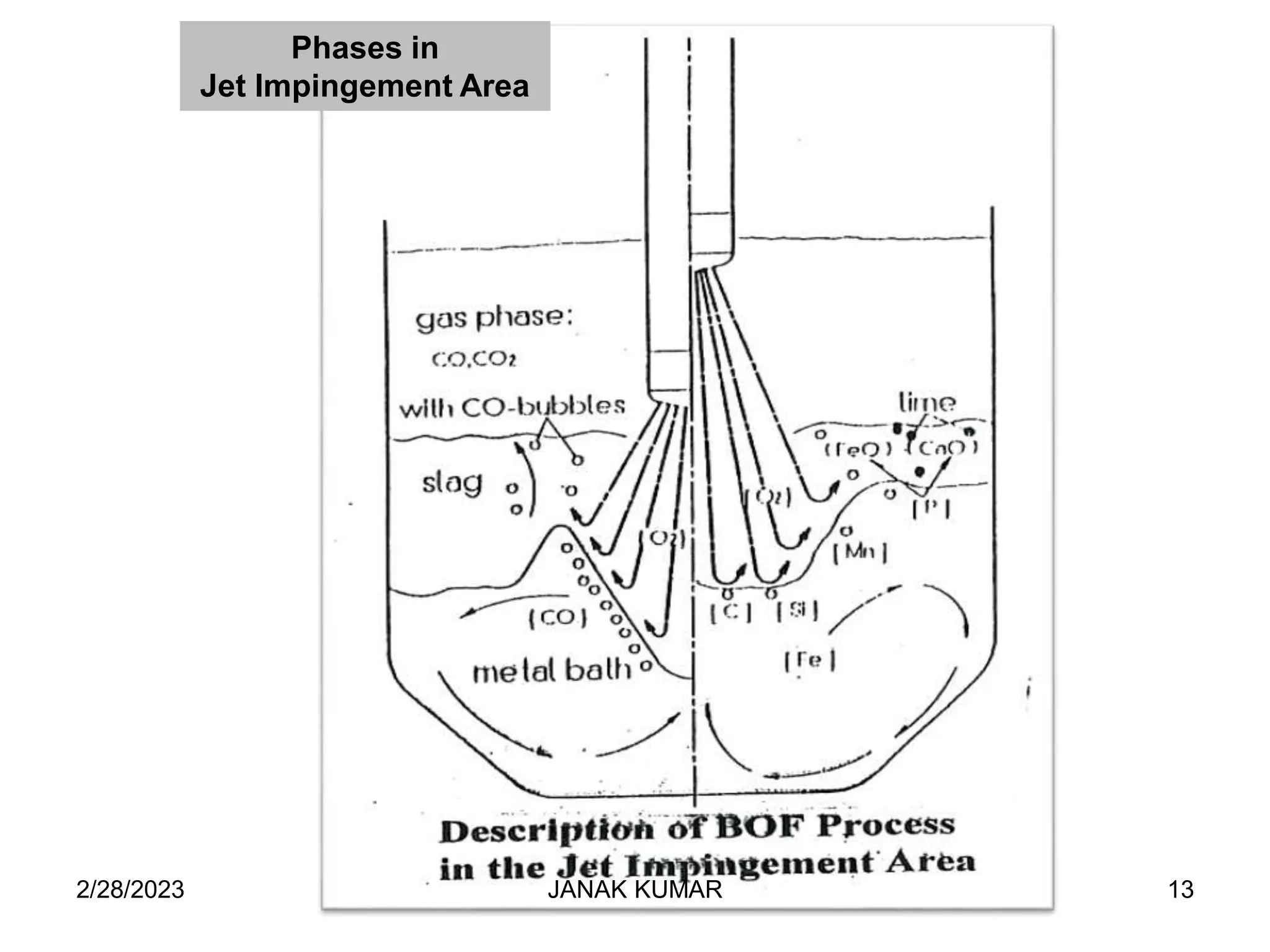

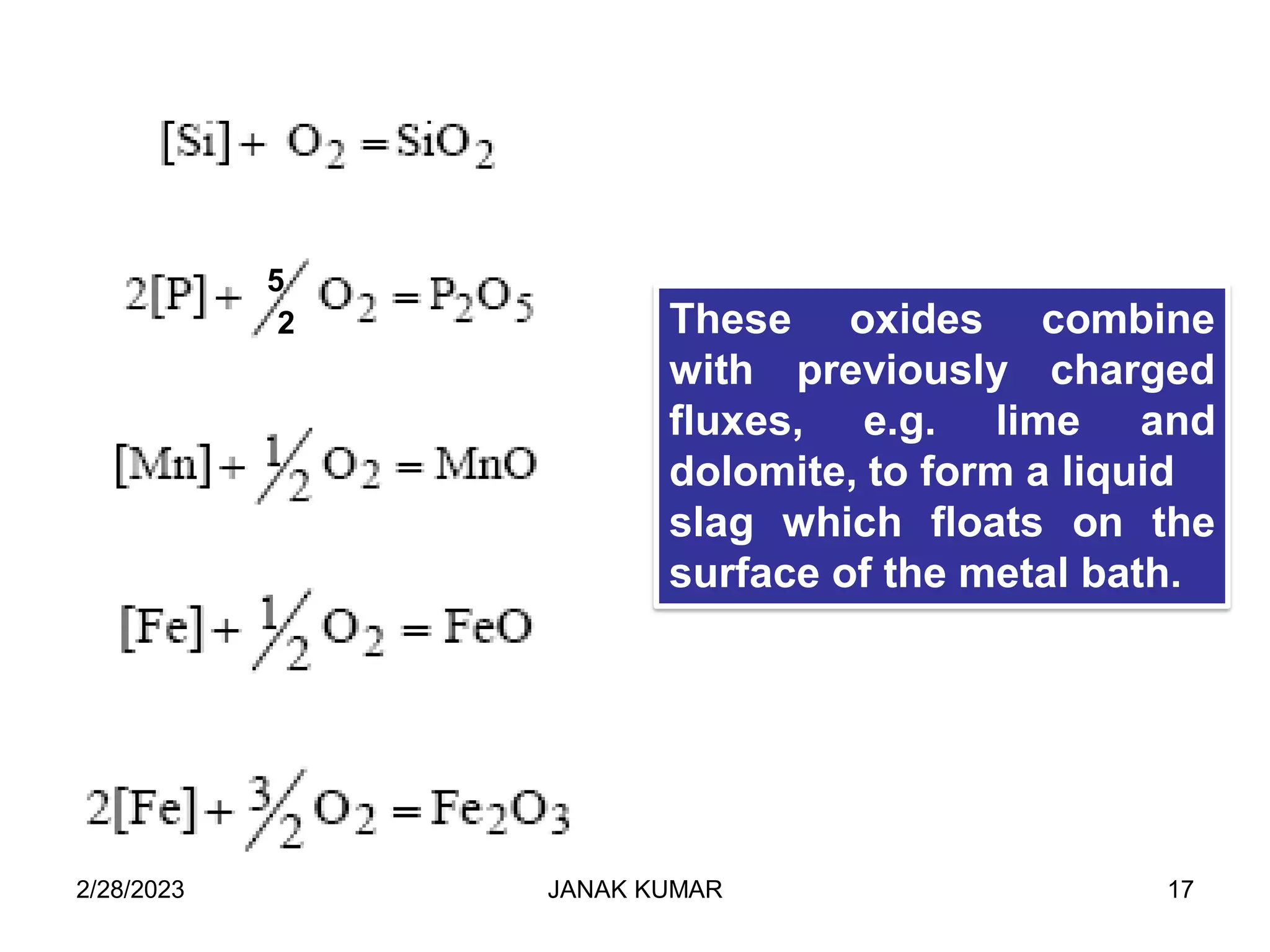

2) The reactions that occur during blowing including decarburization, desulfurization, and removal of phosphorus, silicon, and manganese. Slag composition also changes during this stage.

3) After blowing is complete, the steel is sampled and additional blowing may occur if specifications are not met. Slag is also analyzed to check composition.

![SPECIFICATION

RAW MATERIAL SPECIFICATION DETAILS

Ferro manganese(high C) Mn- 70 % min, C 7.5 % max, SIZE : 25-50mm

Ferro –Silicon Si 70% min, SIZE : 25 -50mm

Ferro niobium Nb 63%min

Ferro-Vanadium V – 50 %min,SIZE : 25 -70mm

Ferro Chrome[ high carbon] Cr - 60 %min.,C- 8%max

Ferro Chrome [low C ] Cr – 60 %min,C - 0.2% max

Alluminum Cubes- 97%,Wire Al – 97%,Shots - 93 %min

Petro coke Fixed Carbon -99.0%min,Moisture 0.1%max,Ash –

0.5 % max Size : 2 -10mm

Silico-Manganese Mn 60%min,Si - 15%min,Size : 25 –50mm

2/28/2023 4

JANAK KUMAR](https://image.slidesharecdn.com/basicoxygenfurnace-230320134506-0cec3821/75/Basic-oxygen-furnace-pdf-4-2048.jpg)

![ HOT METAL

TOTAL SCRAP

TOTAL

TOTAL LIME

SILICO MANGANESE

FERO SILICON

FERO MANGANESE

RAW DOLOMITE

ALUMUNIUM

NICKEL

PETRO COKE

COPPER

OTHER FERRO ALLOYS

SYNTHETIC SLAG

IRON ORE

CALCINED DOLO

OXYGEN

1038.5

96.6

1135.1

44.7

18.5

0.7

0.1

0.6

0.7

0.04

3.7

0.04

0.3

1.1

0.5

27.7

59.7CU METRE/TON

SPECIFIC CONSUMPTION[KG/TON STEEL]

2/28/2023 6

JANAK KUMAR](https://image.slidesharecdn.com/basicoxygenfurnace-230320134506-0cec3821/75/Basic-oxygen-furnace-pdf-6-2048.jpg)

![De-Siliconisation

[Si] + 2(FeO) + 2(CaO) = (2CaO.SiO2) + 2[Fe]

SiO2(Silica) is a very stable oxide and hence

its reversal does not take place.

Hot metal with low Si content is preferred to

decrease lime consumption and minimize

slag volume. High Si in hot metal has an

adverse impact on converter lining.

Reactions during Blowing

2/28/2023 18

JANAK KUMAR](https://image.slidesharecdn.com/basicoxygenfurnace-230320134506-0cec3821/75/Basic-oxygen-furnace-pdf-18-2048.jpg)

![De-Phosphorisation

2[P]+5(FeO)+3(CaO) = (3CaO.P2O5) + 5[Fe]

For effective removal of Phosphorous

slag of high basicity and low

temperature are favourable.

De-Phosphorisation increases with

increasing FeO % in slag.

Reactions during Blowing

2/28/2023 19

JANAK KUMAR](https://image.slidesharecdn.com/basicoxygenfurnace-230320134506-0cec3821/75/Basic-oxygen-furnace-pdf-19-2048.jpg)

![Manganese Removal

[Mn] + (FeO) = (MnO) + [Fe]

De-Carburization

[C] + [O] CO gas

[ ].. Dissolved in steel

( ).. Dissolved in slag

Reactions during Blowing

2/28/2023 20

JANAK KUMAR](https://image.slidesharecdn.com/basicoxygenfurnace-230320134506-0cec3821/75/Basic-oxygen-furnace-pdf-20-2048.jpg)

![De-Sulphurisation

[S] + (CaO) = (CaS) + [O]

For removal of Sulphur, slag of high basicity,

high bath temp. and reducing condition are

favourable. Since BOF steel making is not a

reducing process Sulphur removal is only to

the extent of 30 – 40 %. Higher Slag volume

has a positive effect on Sulphur reduction,

but this in turn adversely effects the

converter life. Hence hot metal having high

S% is not desirable in BOF process.

Reactions during Blowing

2/28/2023 21

JANAK KUMAR](https://image.slidesharecdn.com/basicoxygenfurnace-230320134506-0cec3821/75/Basic-oxygen-furnace-pdf-21-2048.jpg)