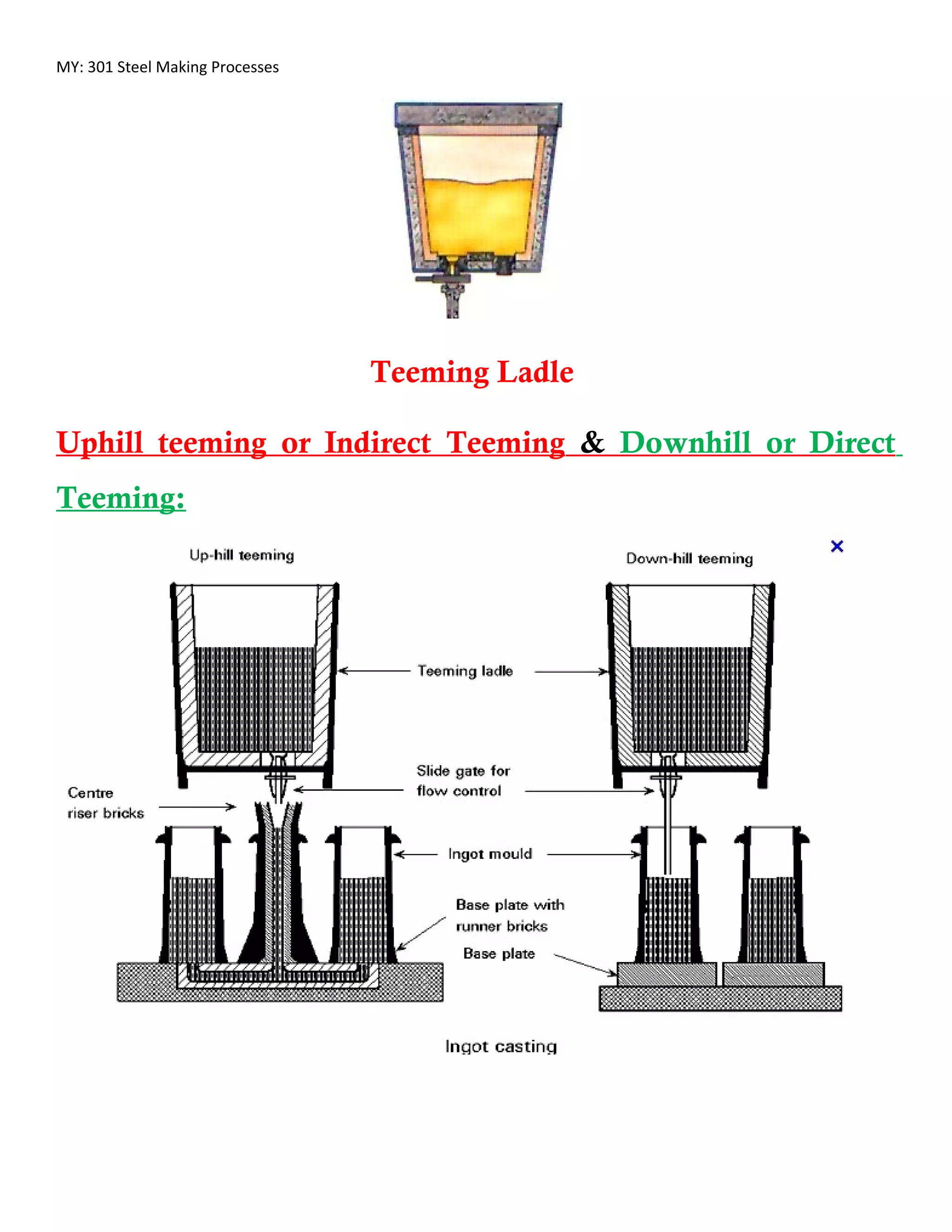

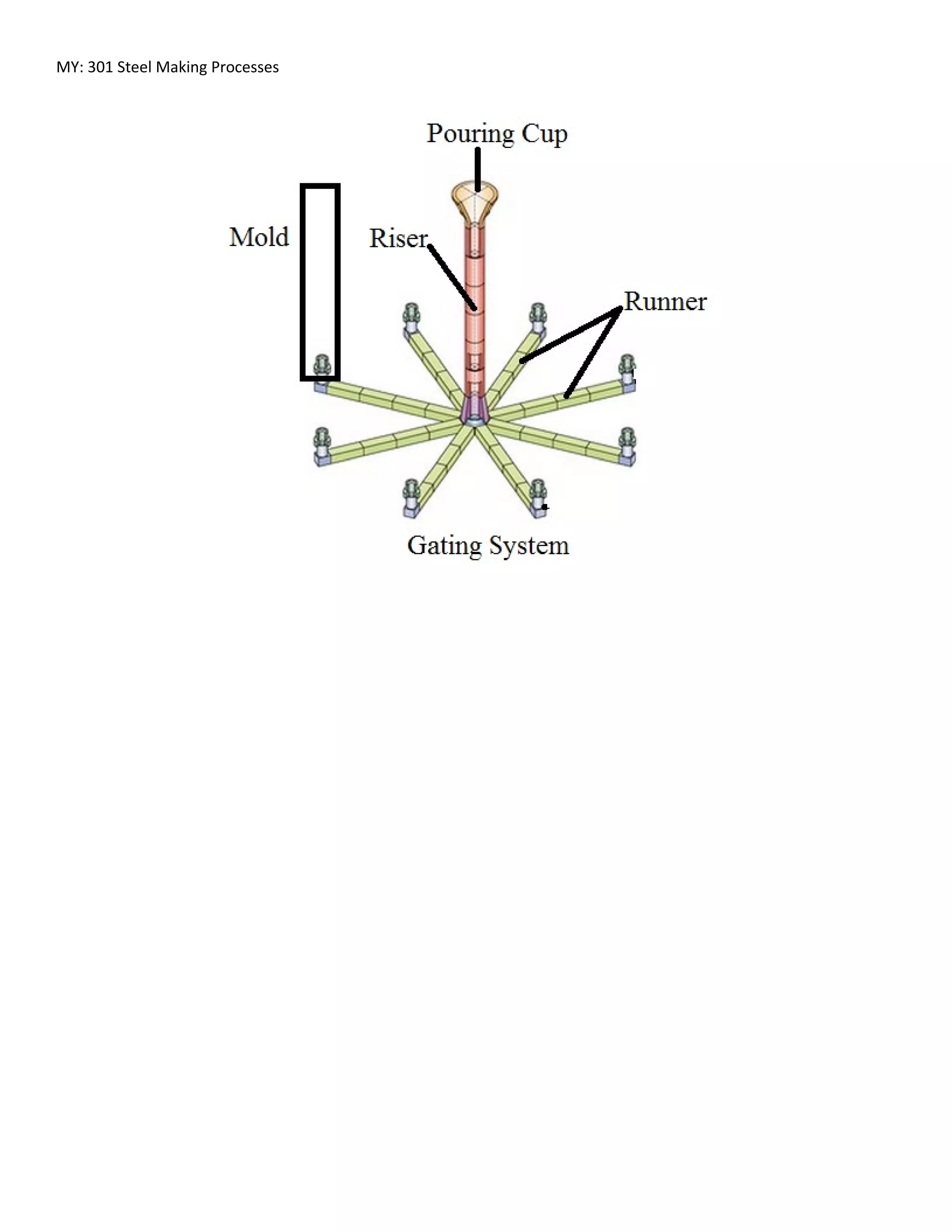

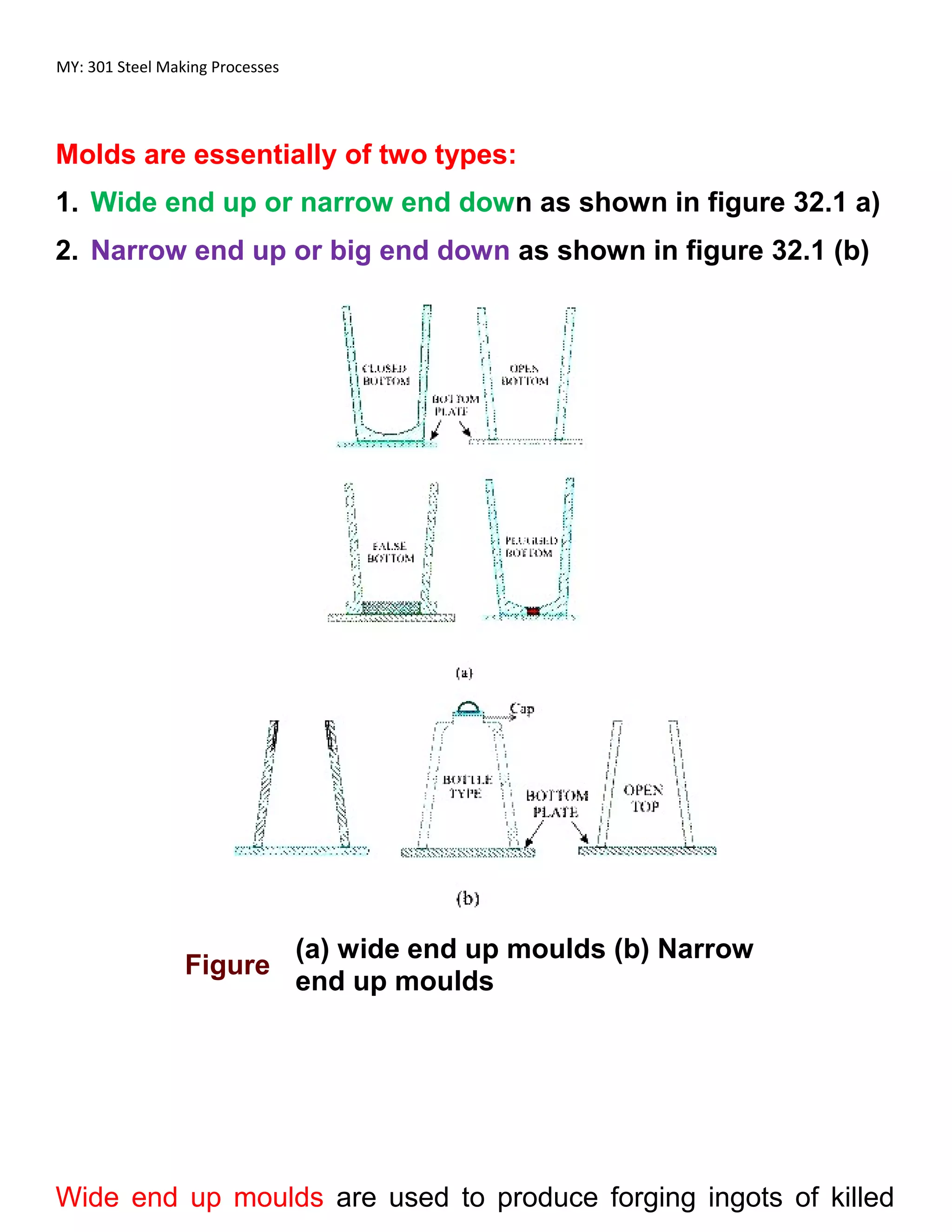

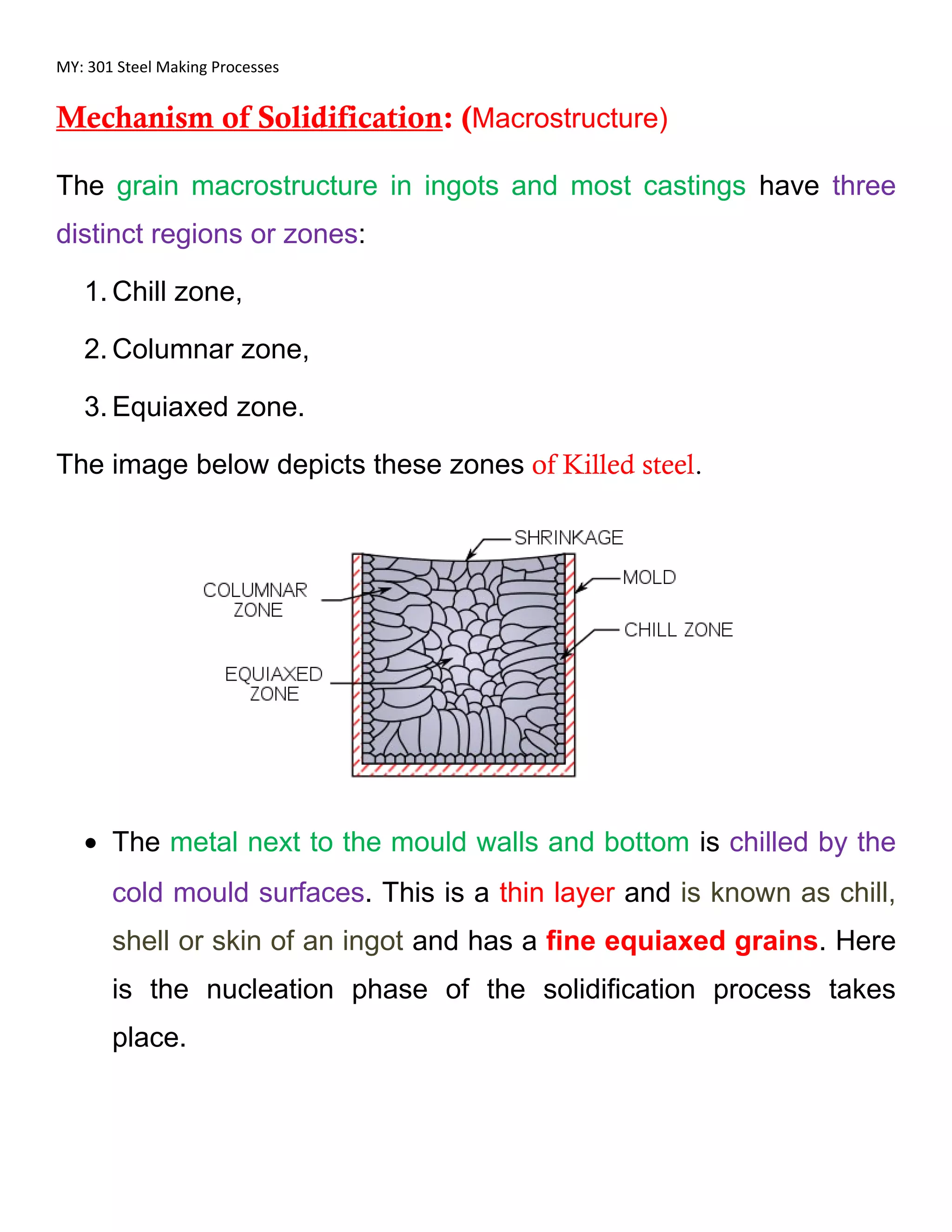

Molten steel is tapped into a ladle and alloying elements are added before being cast into molds. Steel ingots can have square, round, or polygon cross-sections depending on their intended use - squares for rolling, rectangles for flat products, and rounds for tubes. Ingot casting molds are made of cast iron and come in two types - wide end up or narrow end up. As the steel solidifies in the mold, it forms three distinct zones - a thin chill zone against the mold walls, columnar zones of elongated crystals perpendicular to the walls, and an inner equiaxed zone of larger isotropic crystals.