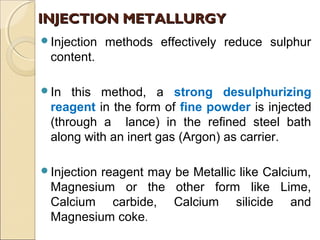

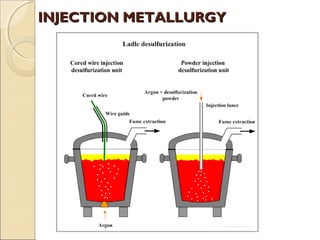

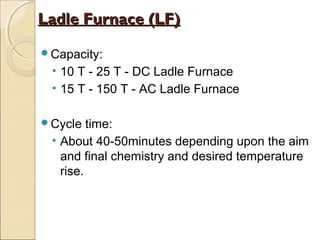

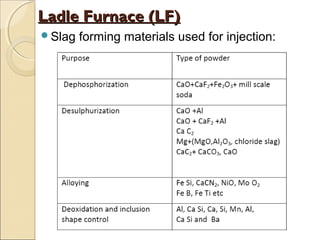

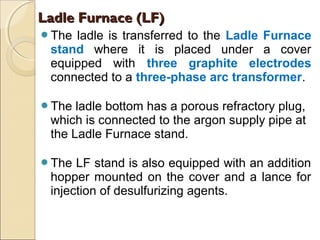

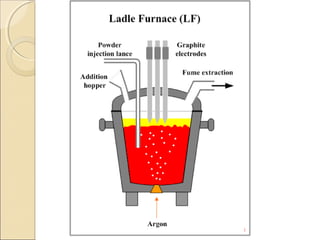

Injection metallurgy and ladle furnaces are used to refine molten steel. In injection metallurgy, desulfurizing reagents are injected into the ladle through a lance using argon gas as a carrier, which helps remove sulfur. Ladle furnaces are used to reheat, stir, and refine steel in a ladle. They allow for desulfurization, alloy additions, and inclusion removal. Both processes make use of slag and can reduce sulfur levels to 0.0002%, improving steel properties.