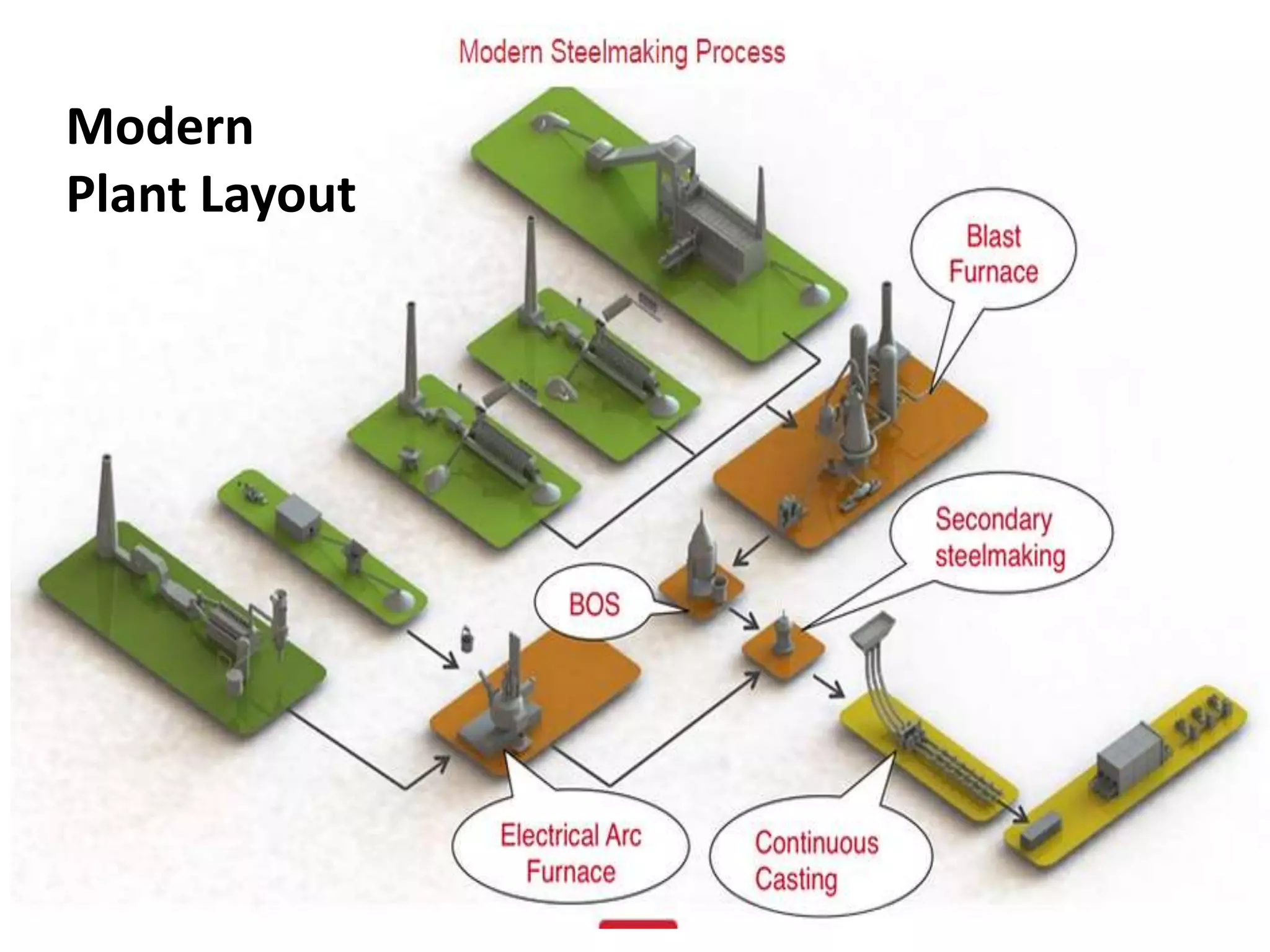

The document discusses the basic oxygen steelmaking (BOS) process and electric arc furnace (EAF) process for steel production. It provides details on:

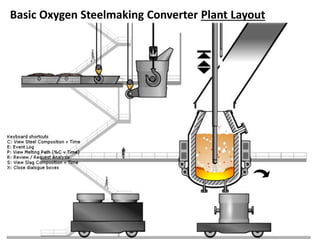

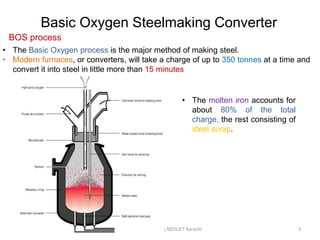

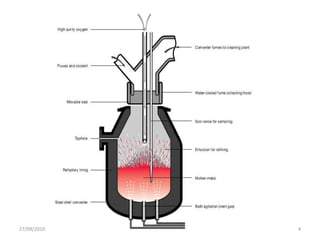

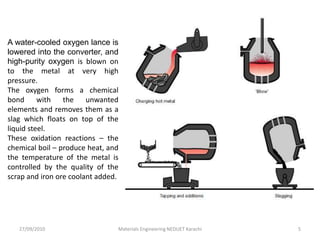

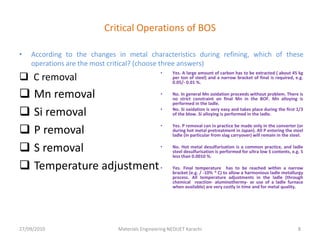

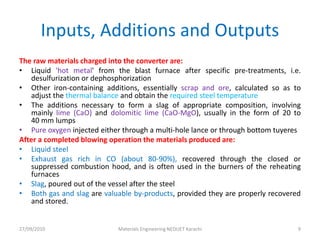

- The BOS process uses oxygen to remove carbon and other impurities from liquid iron in large converters in 15 minutes, producing steel. Critical removal steps are carbon, phosphorus, and temperature adjustment.

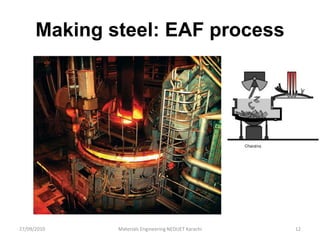

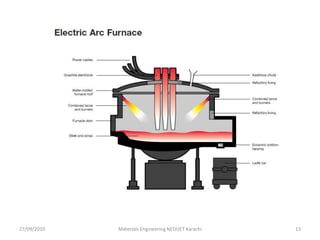

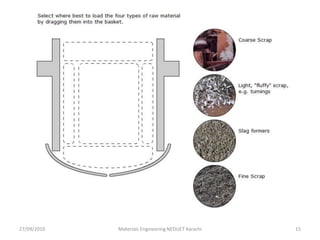

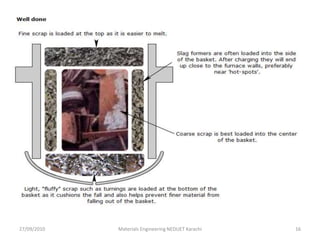

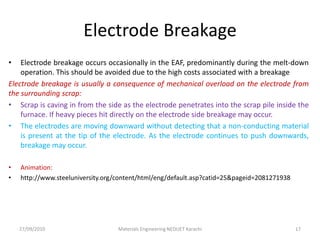

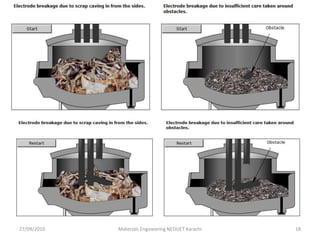

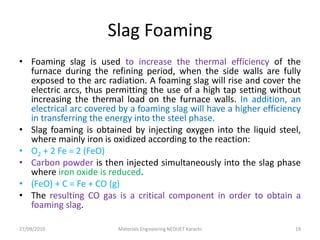

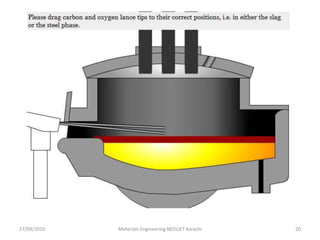

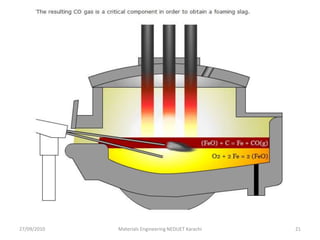

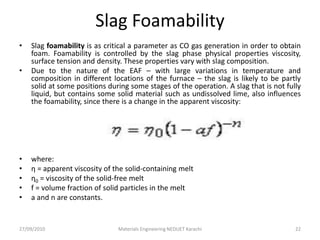

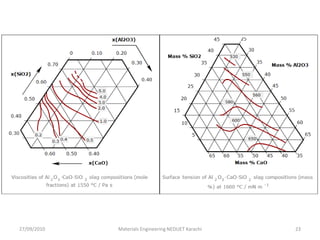

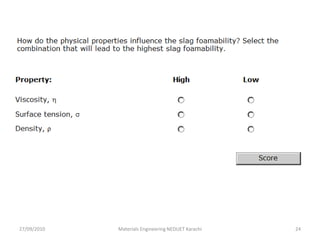

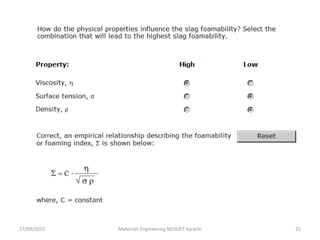

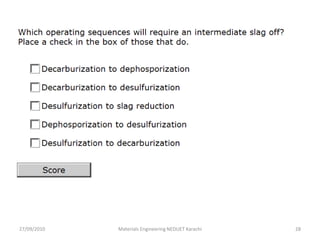

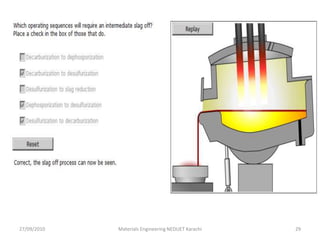

- The EAF melts recycled steel scrap using electric arcs in the furnace. It can perform metallurgical operations like refining. Electrode breakage and slag foaming, properties, and reduction are discussed.

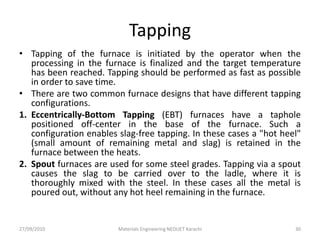

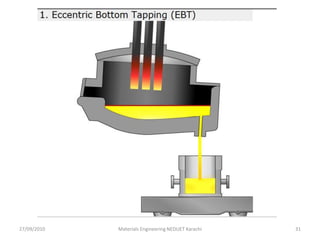

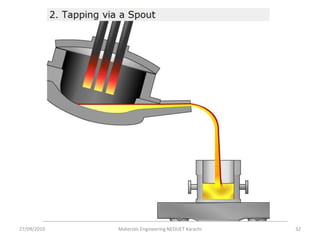

- Both processes conclude by tapping the molten steel into a ladle for further refining before casting.