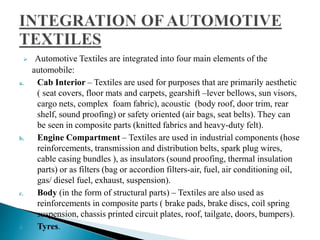

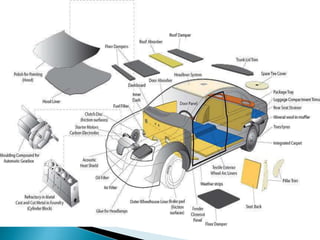

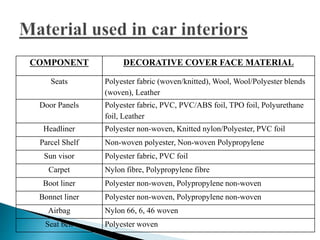

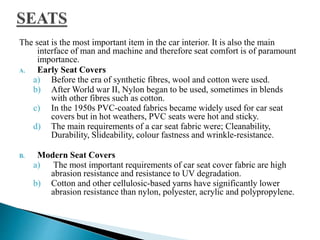

The document discusses the use of technical textiles in the automobile industry. It notes that textiles are used for over 80 parts in each car, providing functions like insulation, durability, comfort, and safety. Textiles are essential components of tires, hoses, belts, filters, composites, and safety devices. They require properties like high tenacity, modulus, temperature resistance, and are used extensively in interiors, engines, vehicle bodies, and tires. The Indian automobile industry is one of the largest and fastest growing globally.