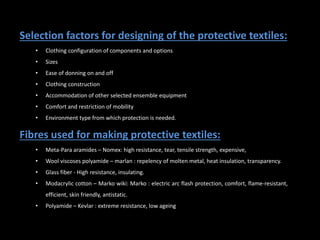

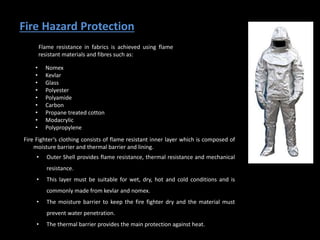

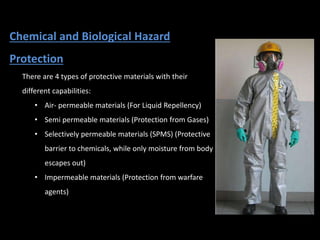

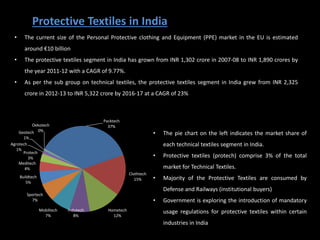

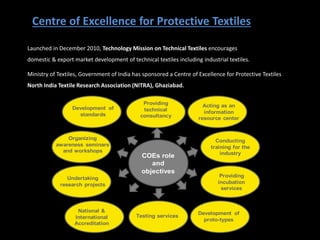

The document provides a comprehensive overview of protective textiles, emphasizing their role in safeguarding users against various hazards such as thermal, biological, and chemical threats. It details the materials used, applications across various industries, and the growth of the protective textiles market in India. Additionally, it highlights the establishment of a Centre of Excellence for protective textiles aimed at fostering industry development and innovation.