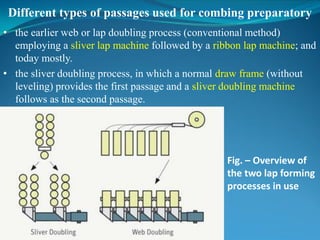

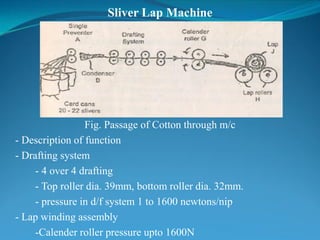

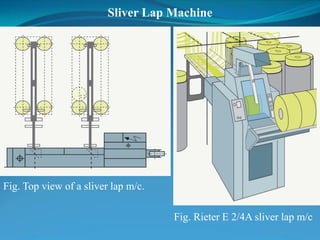

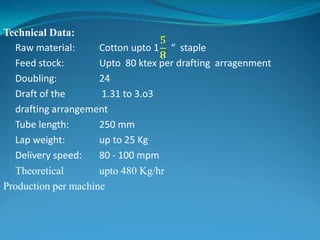

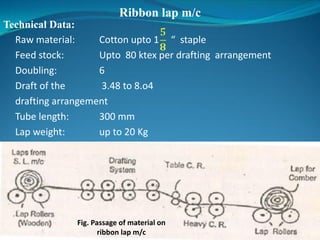

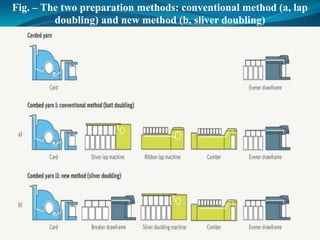

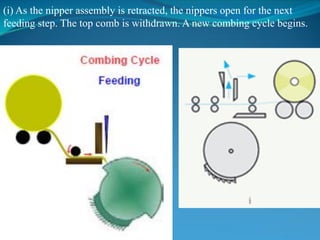

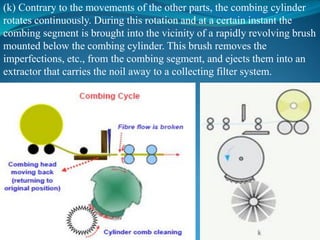

The document discusses combing preparatory processes. It describes the need for combing preparatory, which includes fiber straightening, reversing fiber flow, and producing a flat sliver. Traditionally, this involved a sliver lap machine and ribbon lap machine, but now mostly uses a draw frame and sliver lap machine. The objectives of combing preparatory are to straighten fibers, reverse flow, maximize leading fiber hooks, and produce a flat sliver. Different machine types and their functions are explained, including parameters that influence the combing operation and quality of the finished product.

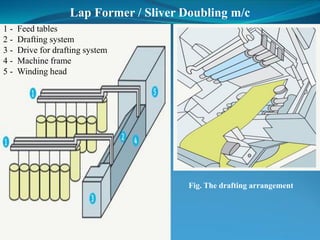

![- 4/5 drafting system

- drafting capacity 10, generally working draft 8.

- Three sliver creel with stand, each has capacity 20 and are double

sided. Hence, 60 doublings possible.

- Maximum total draft of 3.75 with 60 doubling.

- Lap weight 1200 grains/yard [85 gms/m]

- Production rate 250-290 Kg/hr

Fig. Sliver feeding at super lap former](https://image.slidesharecdn.com/comber-180912060236/85/Yarn-Manufacturing-Process-Comber-Part-I-21-320.jpg)

![Preparation of stock for combing

[System of lap preparation configuration of fibre feed and its effect on

the quality of product]

Fig. – Clamped slivers between

the nipper plates

Fig. – Fibers projecting from

the nippers](https://image.slidesharecdn.com/comber-180912060236/85/Yarn-Manufacturing-Process-Comber-Part-I-22-320.jpg)

![Types of Application

The amount of material combed out varies within the range between

8% and 25% of the infeed stock.

1] For Long Staple combing mills:

Processing first-class, expensive cotton of high strength,

containing a low proportion of short fibers and little dirt.

The product is a fine to very fine yarn of top quality.

The demands placed on know-how and skill of operating personnel

is correspondingly high, as they are on the design

and maintenance of the machines.

Yarn production is low, while generation of noil is high.](https://image.slidesharecdn.com/comber-180912060236/85/Yarn-Manufacturing-Process-Comber-Part-I-31-320.jpg)

![2] For Medium-staple combing mills:

Medium cotton qualities with a wide spread of quality parameters are

spun into medium (to fine) yarns of good quality at economic production

costs.

The process is problematic in that it has to achieve a high strand of

quality and at the same time give high production at low cost.

The maximum demands placed on medium staple combing can only

be fulfilled by optimally trained personnel.

3] Short to Medium staple combing mills:

Raw material used have the same as that for production of carded

yarns.

In this combination with low level noil level (6 – 14%).

This process is the most widely used in practice; it is technologically

undemanding and can be operated without problems when good m/c

are available.](https://image.slidesharecdn.com/comber-180912060236/85/Yarn-Manufacturing-Process-Comber-Part-I-32-320.jpg)

![Influences of the feed stock on combing

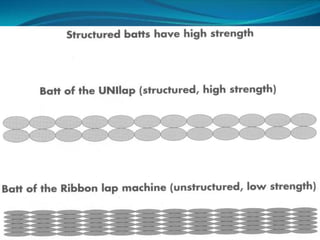

1. Parallalisation of the fibres in the batt / lap

2. Batt / lap Thickness[Weight]

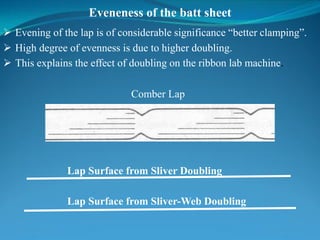

3. Eveneness of the batt / lap sheet

4. The disposition of the hooks](https://image.slidesharecdn.com/comber-180912060236/85/Yarn-Manufacturing-Process-Comber-Part-I-50-320.jpg)

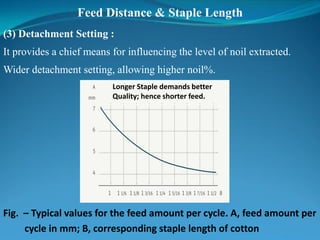

![Lap / Batt Thickness[Weight]

Fig. – Batt weight in relation to staple length](https://image.slidesharecdn.com/comber-180912060236/85/Yarn-Manufacturing-Process-Comber-Part-I-55-320.jpg)

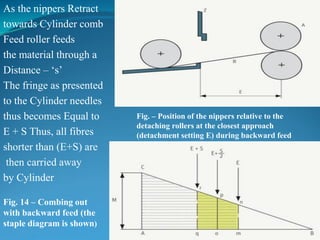

![Derivation of Gegauff’s expression:

• The ‘po’ is dividing line representing a length (E+s/2). Further, in

similar triangles, the ratio of the areas are proportional to squares of

the sides, and as the areas represents the noil percentage based on the

ratio of weight of noil to that of feed stock, following can be stated :

∆opB (op)2

• Noil (p%) = ------ x 100 = ------- x 100

∆ABC (AC)2

= [ E + s/2]2 / M2 x 100](https://image.slidesharecdn.com/comber-180912060236/85/Yarn-Manufacturing-Process-Comber-Part-I-70-320.jpg)

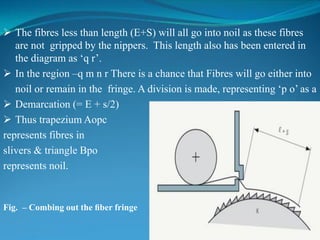

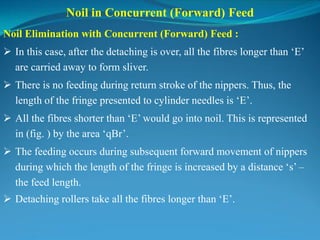

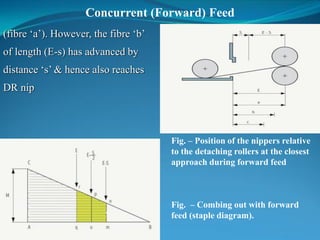

![Concurrent (Forward) Feed

Fibre ‘C’, still shorter than distance (E-S), thus will not be able to

reach the detaching roller nip.

With earlier logic the diagram (fig. ), gives three lines representing –

‘E’, ‘E-S/2’ and ‘E-S’ lines.

Thus, percentage of noil will be –

Noil% = [ ∆(opB) / ∆(ABC)] x 100

= [ (op)2 / AC2] x 100

= [E – (S/2)2 / M2] x 100 (Forward feed)

and [E+ (S/2)2 / M2] x 100 (Backward feed)

From the two derived expressions, it follows that in Counter

(Backward) Feed, the noil level is increased as the feed distance is

raised. Whereas, in the Concurrent (Forward) Feed, the noil is

reduced.](https://image.slidesharecdn.com/comber-180912060236/85/Yarn-Manufacturing-Process-Comber-Part-I-73-320.jpg)