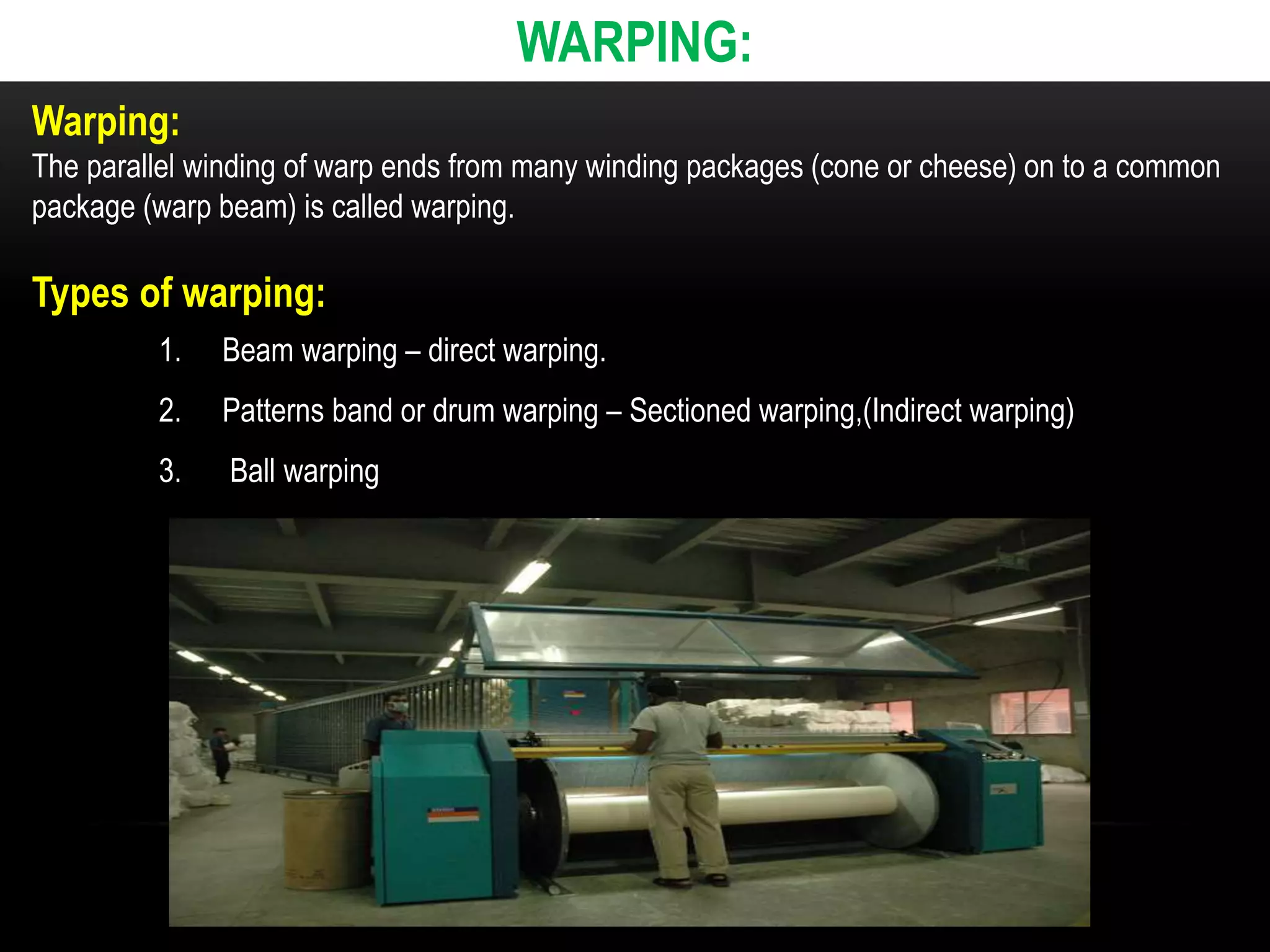

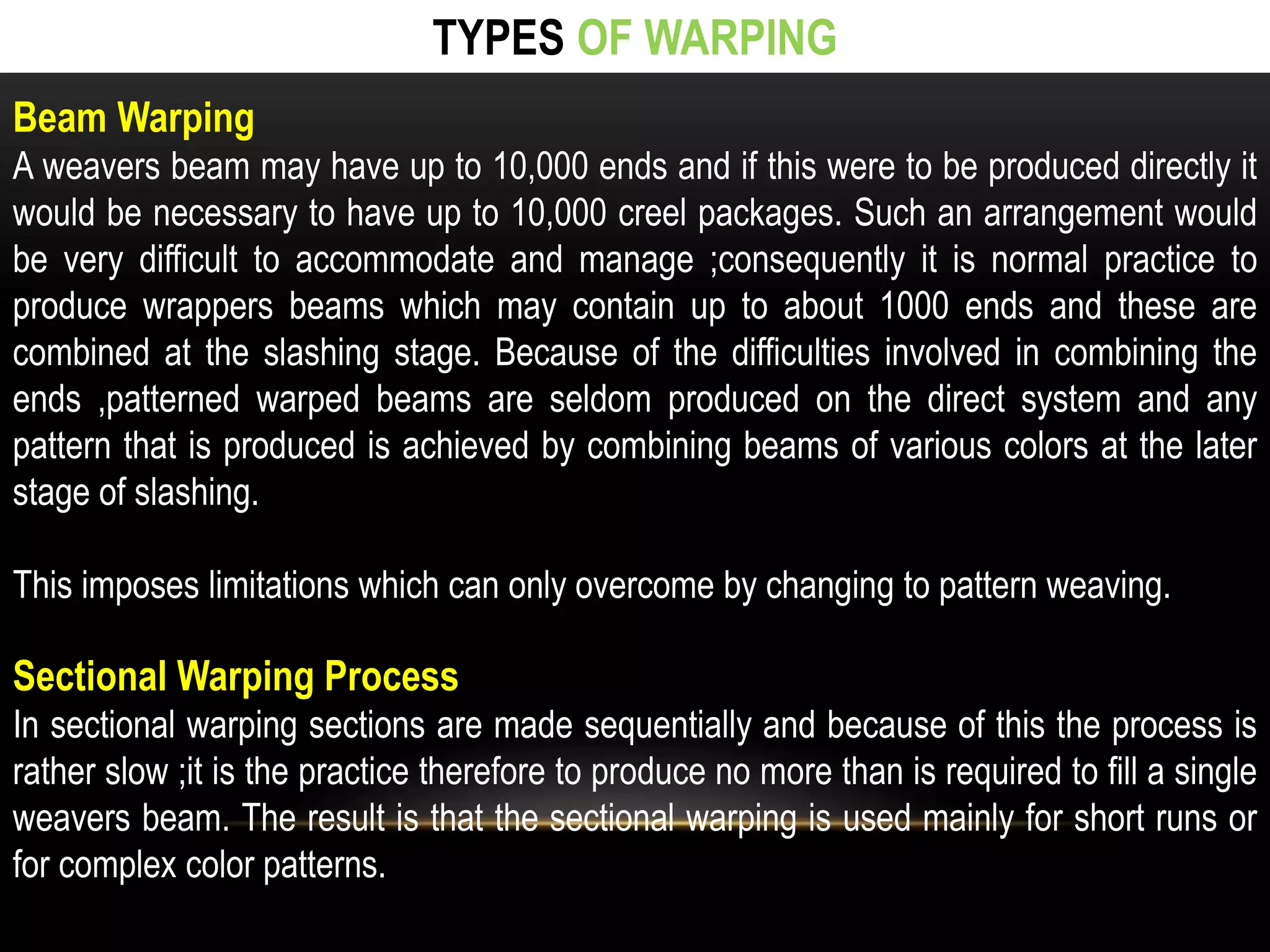

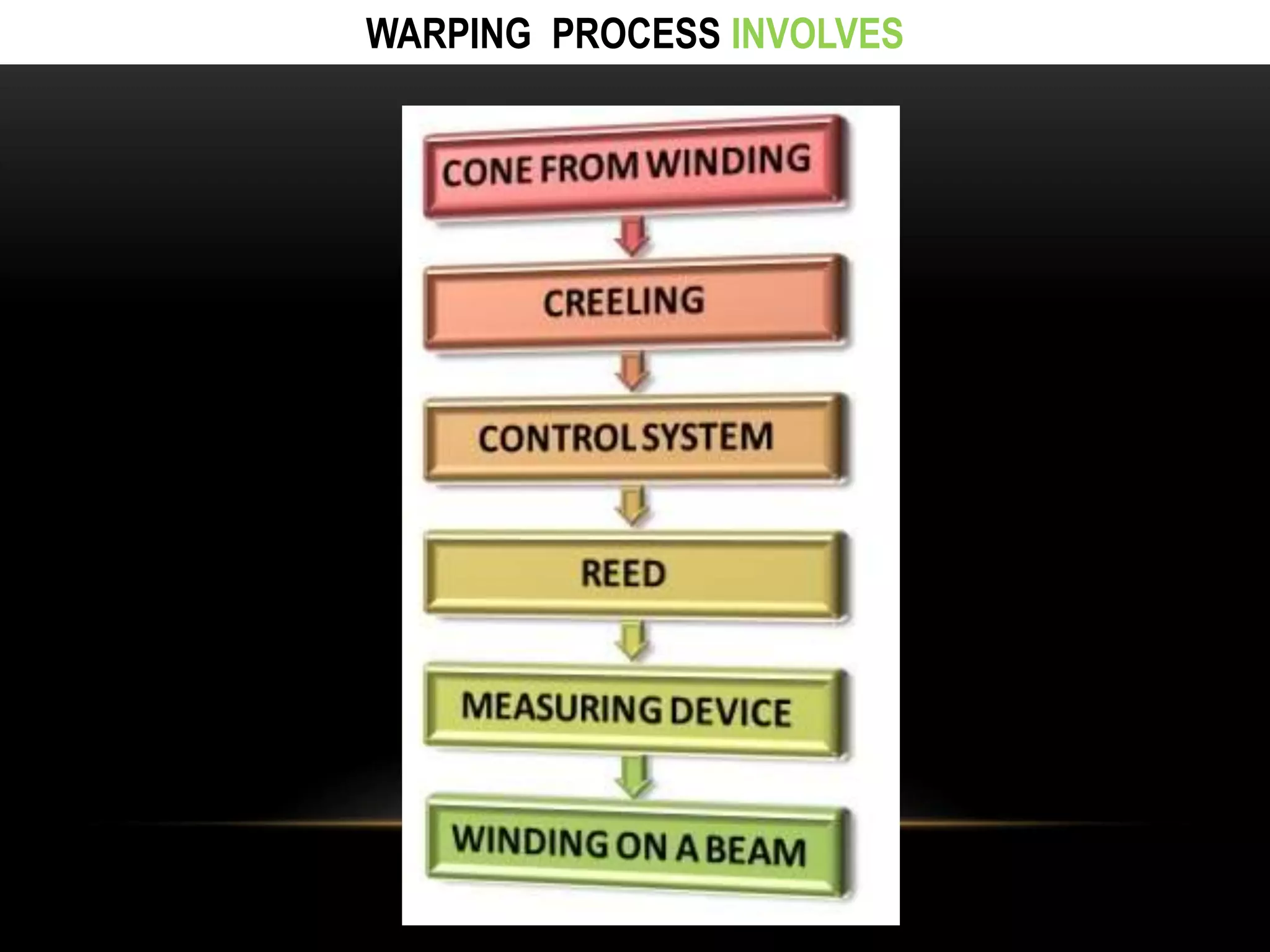

This document provides information about different types of warping processes and warping machines. It discusses beam warping, patterned band warping, and ball warping. It describes the components and functions of direct and sectional warping machines. Direct warping machines wind yarn directly onto beams while sectional warping machines produce beams in two stages by first winding yarn onto a drum and then rewinding onto a beam. Maintaining uniform tension and spacing of yarn ends is important for producing quality warps. Common faults like broken ends, uneven beams, and snarl formations are also summarized along with their causes and remedies.