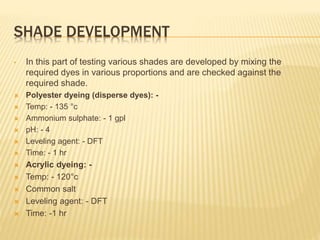

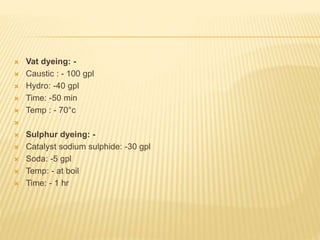

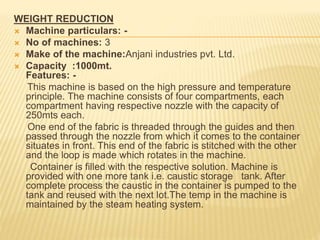

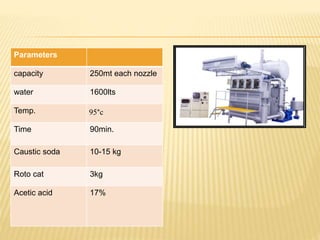

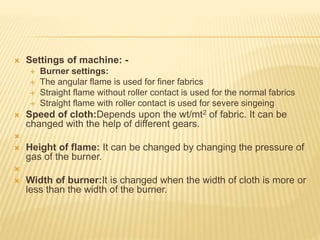

This document provides information about BSL Ltd., a textile company that manufactures fashion fabrics and wool yarn. It discusses the company's departments including quality control, processing, dyeing, and finishing. It describes the various machines and processes used in quality testing, fabric processing, dyeing, weight reduction, drying, and finishing. Key areas covered include quality control procedures for incoming materials, fabric testing at different stages, shade development, and parameters for dyeing and finishing processes.

![ The dyeing operation is done by two methods in BPL INDUSTRIES.

1. Fiber Dyeing

2. Piece Dyeing

1. Fiber Dyed Fabric:

In this type of fabric fibre or yarn is dyed before weaving process or in other words fabric is

already dyed. So only pre-treatment is given to F/D fabric. Therefore no. of machines as well as

cost of processing is less.

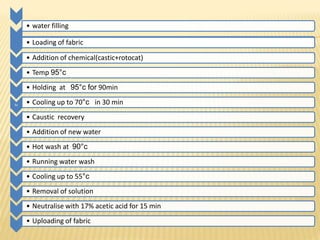

The typical sequence of processes given to fiber dyed fabric is as following:

Stitching

Singeing

[Gas Singeing Machine]

Scouring

[Jumbo Jigger, Relax Scouring Machine]

Drying

Heat Setting

[Stenter]

Chemical Finishing

[Stenter]

Mechanical Finishing

{OD,KD,0/0,Super finish}

](https://image.slidesharecdn.com/seminaronbsl-200519130824/85/Advance-textile-processing-9-320.jpg)

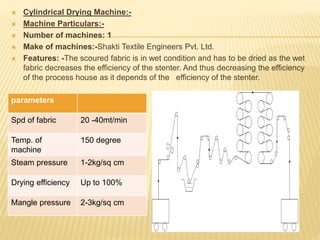

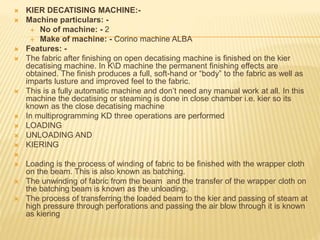

![Parameters

Beam Capacity 600mt.

Beam Diameter 98-103cm. at104cm.

Batching automatic

stop.

Decatising time 15-20min.

Speed 75mt./min.

[loading &

unloading]

Kier pressure 3-4 kg/sq cm

Kier temp. 1090C](https://image.slidesharecdn.com/seminaronbsl-200519130824/85/Advance-textile-processing-28-320.jpg)