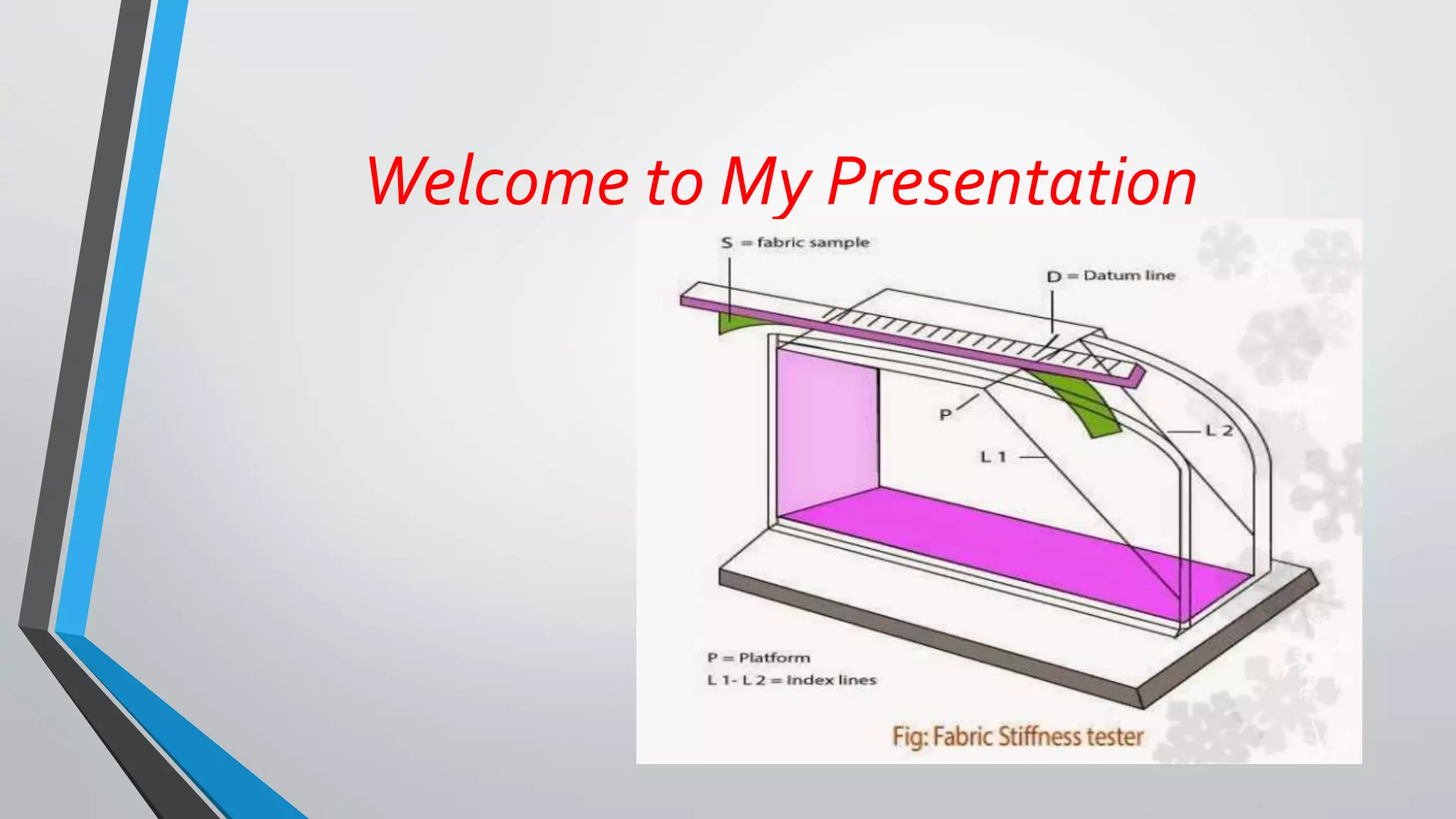

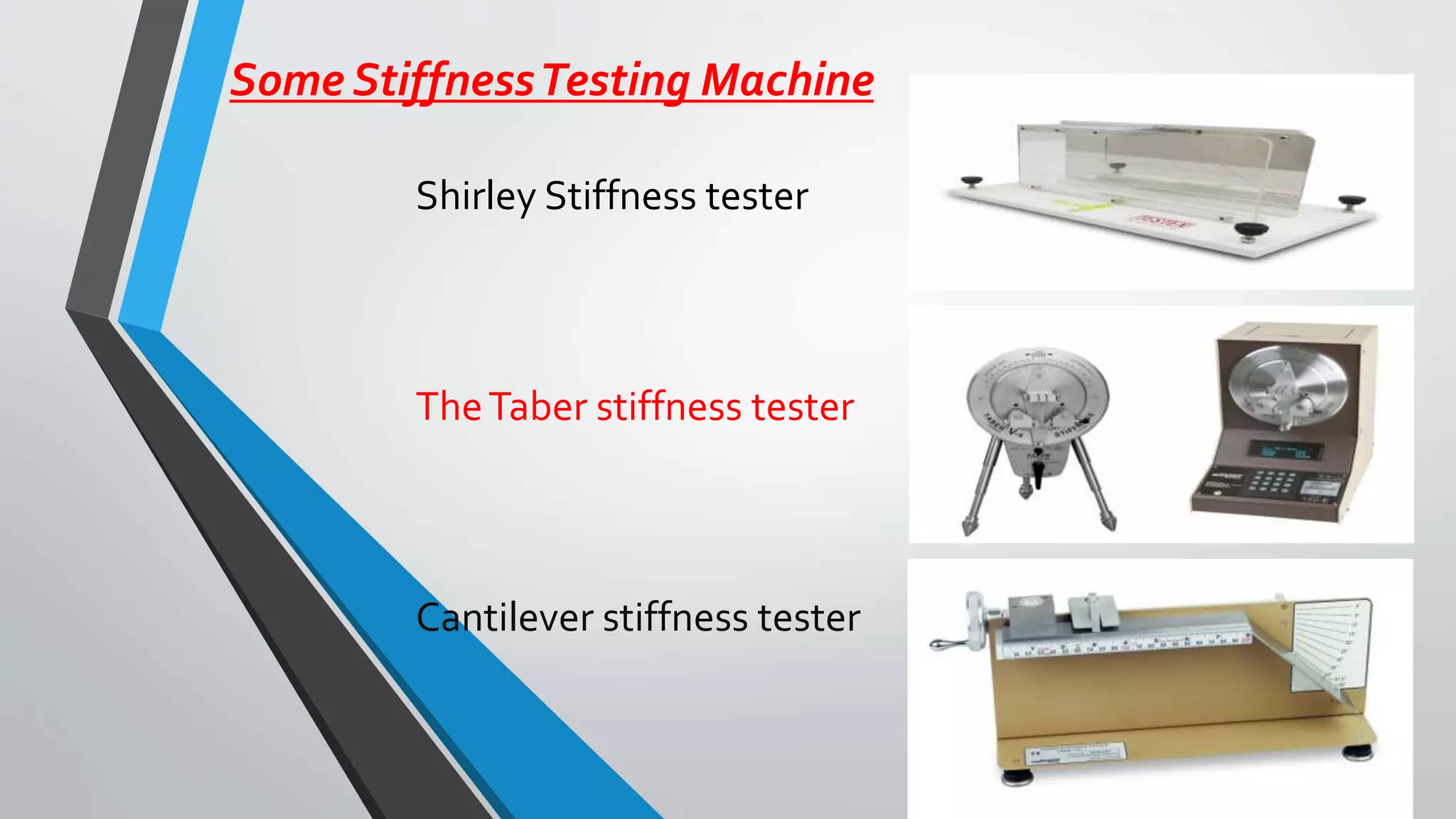

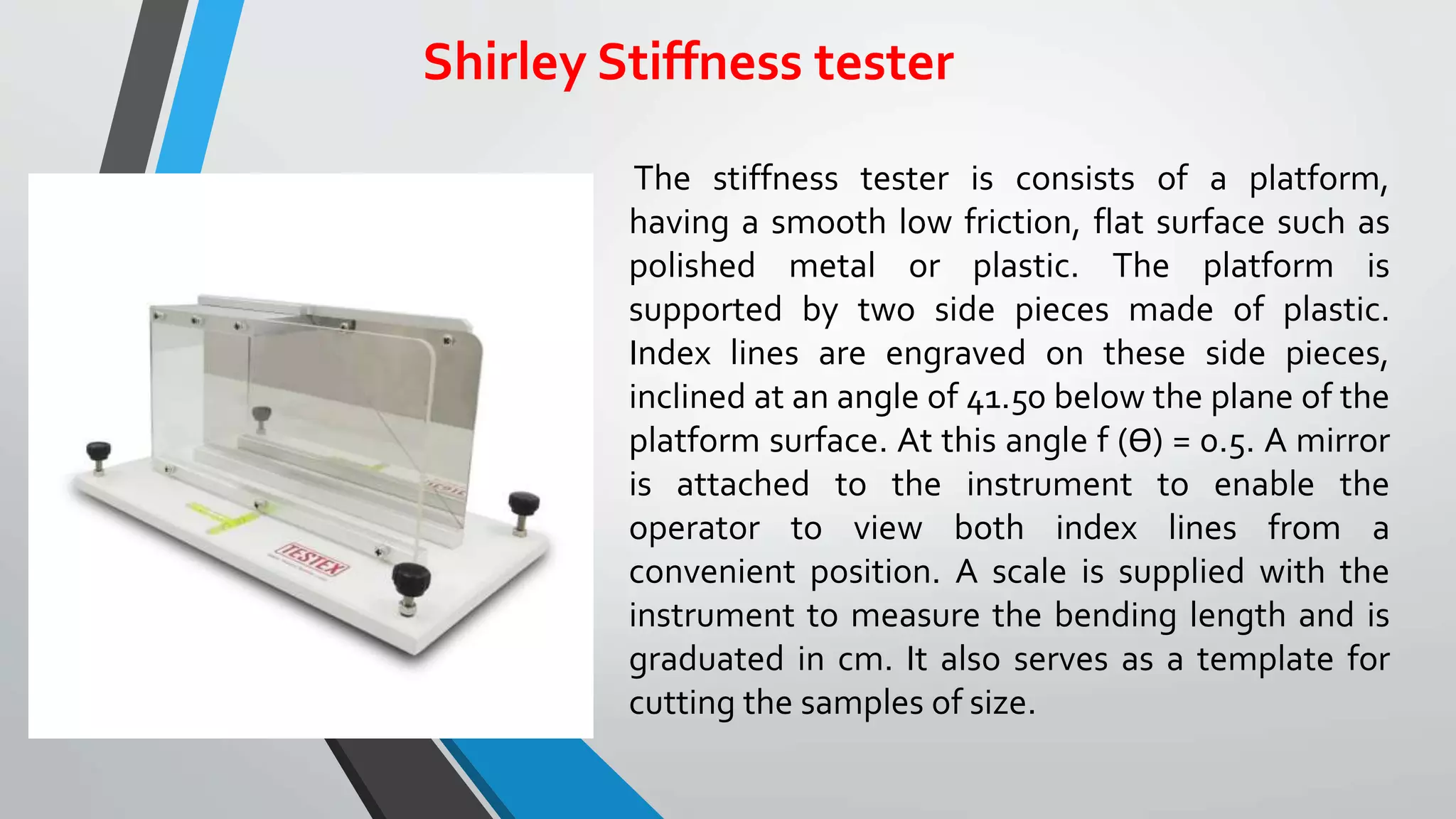

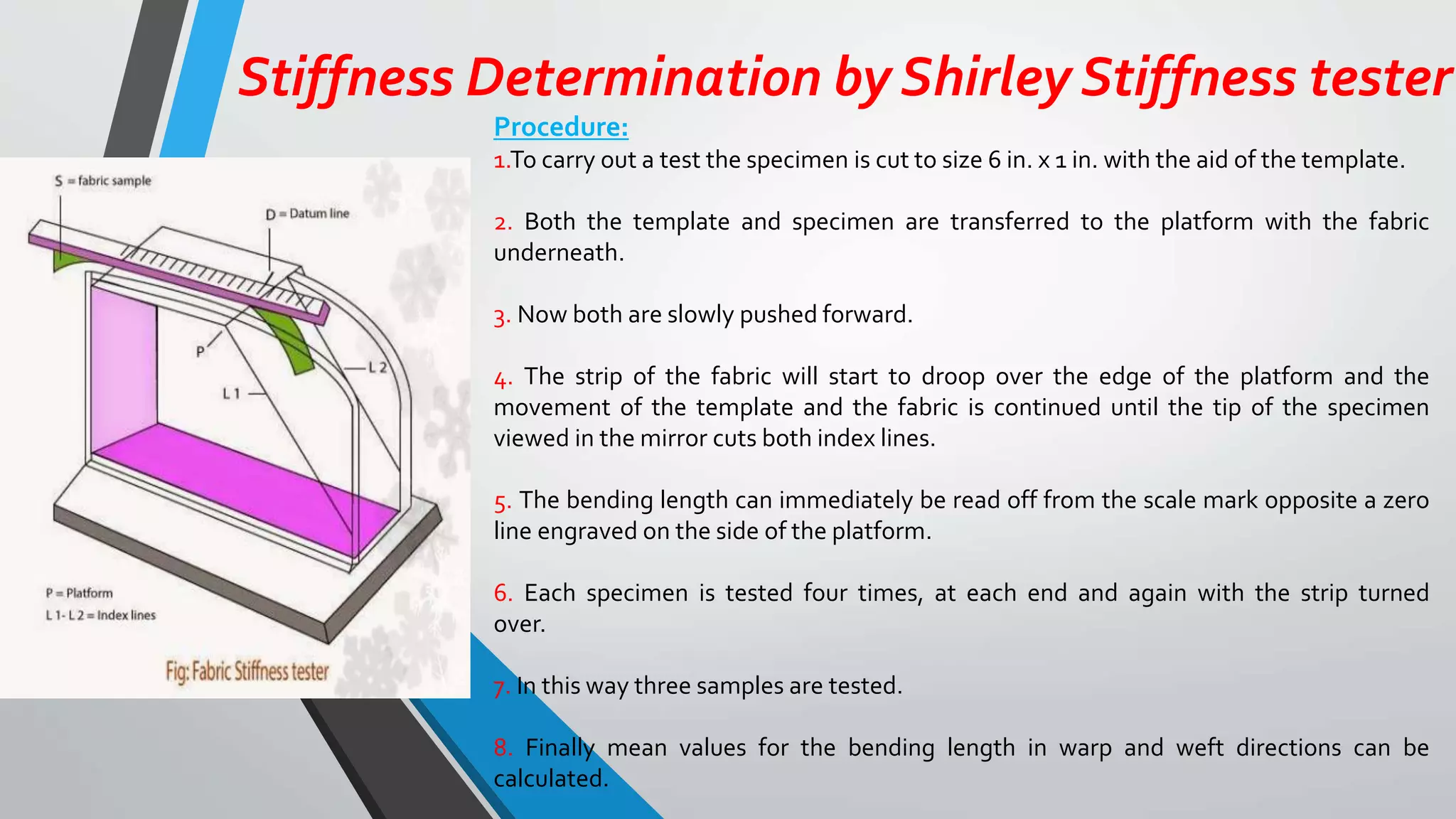

This presentation discusses the stiffness, handle, and drape properties of fabrics. It will cover stiffness and how it is tested using machines like the Shirley Stiffness tester. It will also discuss fabric handle properties, the factors that influence handle, and how to measure drape properties using a drape tester to determine the drape coefficient. Relevant apparatus and testing procedures will be explained.