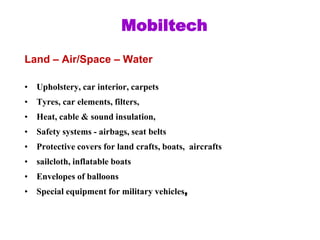

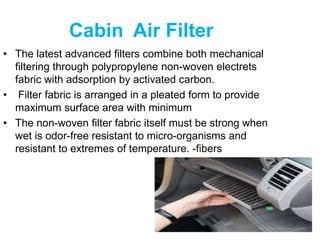

1) Textiles are used widely in automobiles for both visible and concealed components. Visible textiles include upholstery, carpets, and headliners, while concealed textiles are used in tyre cords, hoses, airbags, filters, and more.

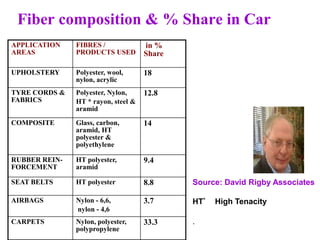

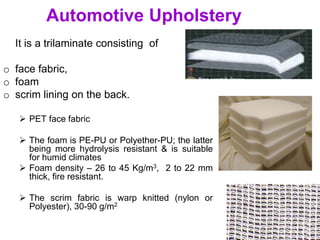

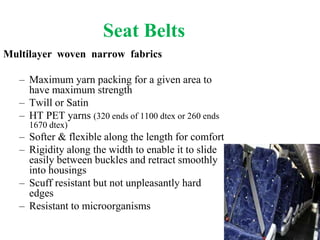

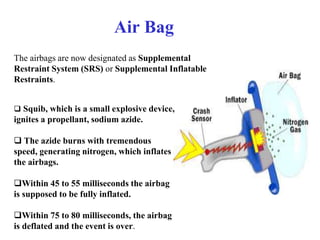

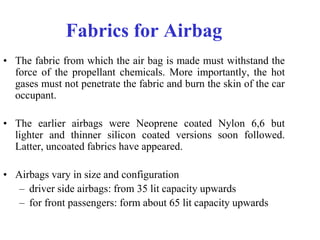

2) Different fibers are used for different automobile components depending on the required properties. For example, polyester is commonly used for upholstery due to its strength and durability, while nylon is used for seat belts and airbags due to its high tensile strength.

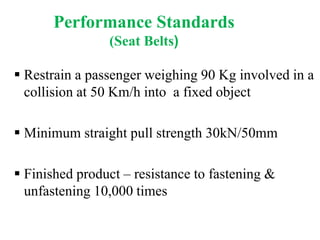

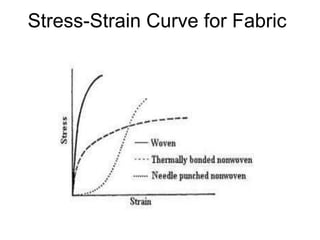

3) Automotive textiles must meet stringent performance standards regarding properties like strength, abrasion and heat resistance, flame retardancy, and durability