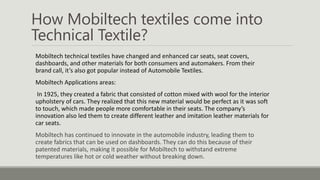

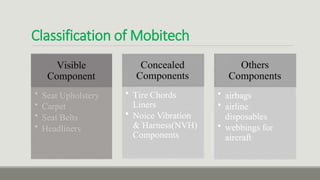

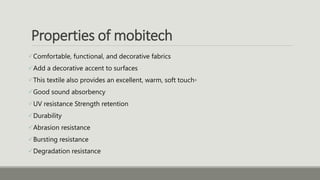

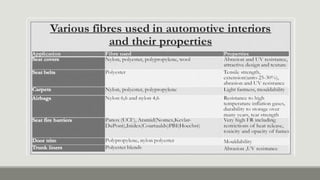

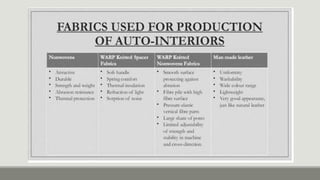

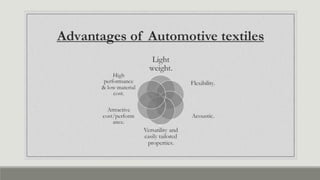

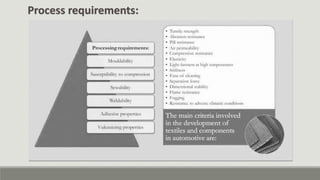

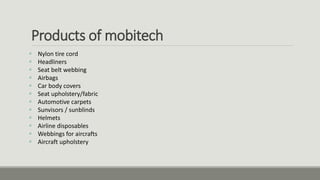

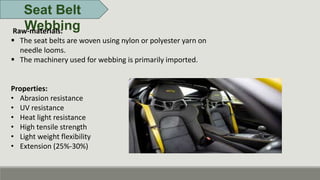

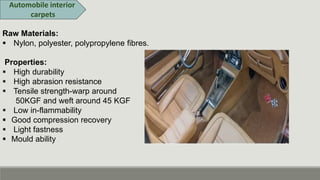

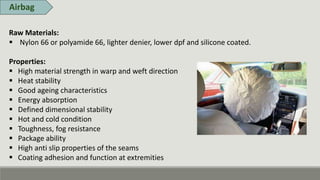

Mobiltech refers to technical textiles used in the automotive and transportation sectors. It includes a wide range of applications and covers comfort, style, isolation, and protection. Common products include seat belts, airbags, headliners, tires, and carpets. Mobiltech textiles must meet important properties like durability, strength, and abrasion resistance. The industry is growing due to rising automobile production and adoption of technical textiles in new automotive applications.