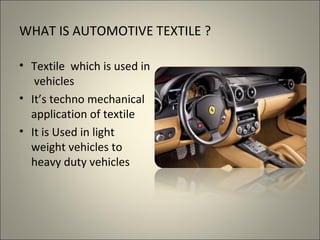

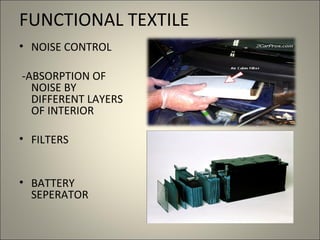

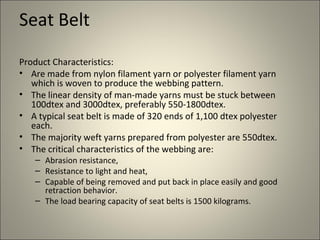

This document discusses various types of automotive textiles including seat covers, sun visors, seat belts, interior carpets, air bags, insulating felts, nylon tyre cord fabric, and headliners. It describes the functions and characteristics of each textile. Seat covers are made from various fabrics and provide comfort. Sun visors block sunlight from the windshield. Seat belts are woven from high strength fibers to secure passengers during collisions. Air bags are made from nylon or polyester fabrics and protect the head and chest in crashes. Insulating felts provide noise and thermal insulation. Nylon tyre cord fabric provides strength to tires. Headliners are non-woven materials used as lightweight roof