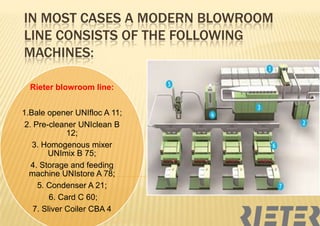

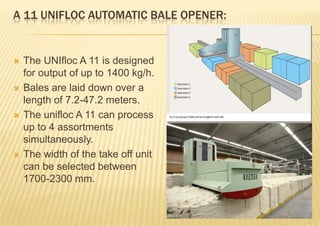

The document describes a modern blowroom line consisting of machines from Rieter, including a bale opener, pre-cleaner, homogeneous mixer, precision blender, storage and feeding machine, condenser, card, and sliver coiler. It provides details on the functions of the Rieter bale opener, pre-cleaner, mixer, blender, storage machine, and condenser and card, which work together to open, clean, blend, feed, and condense cotton fibers into sliver in the blowroom process.