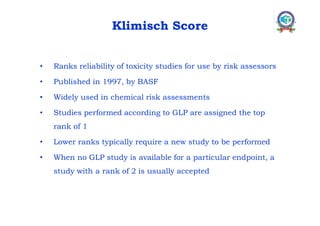

GLP (Good Laboratory Practice) is a quality system for non-clinical health and environmental safety studies. It aims to ensure quality, uniformity, consistency, reproducibility, traceability, reliability and integrity of test data. Key aspects of GLP include standardized procedures for conducting studies, recording and reporting data, and archiving records and materials. GLP was established after fraud was discovered in toxicology lab data submitted to regulators. Adherence to GLP helps ensure the reliability and integrity of non-clinical safety studies.