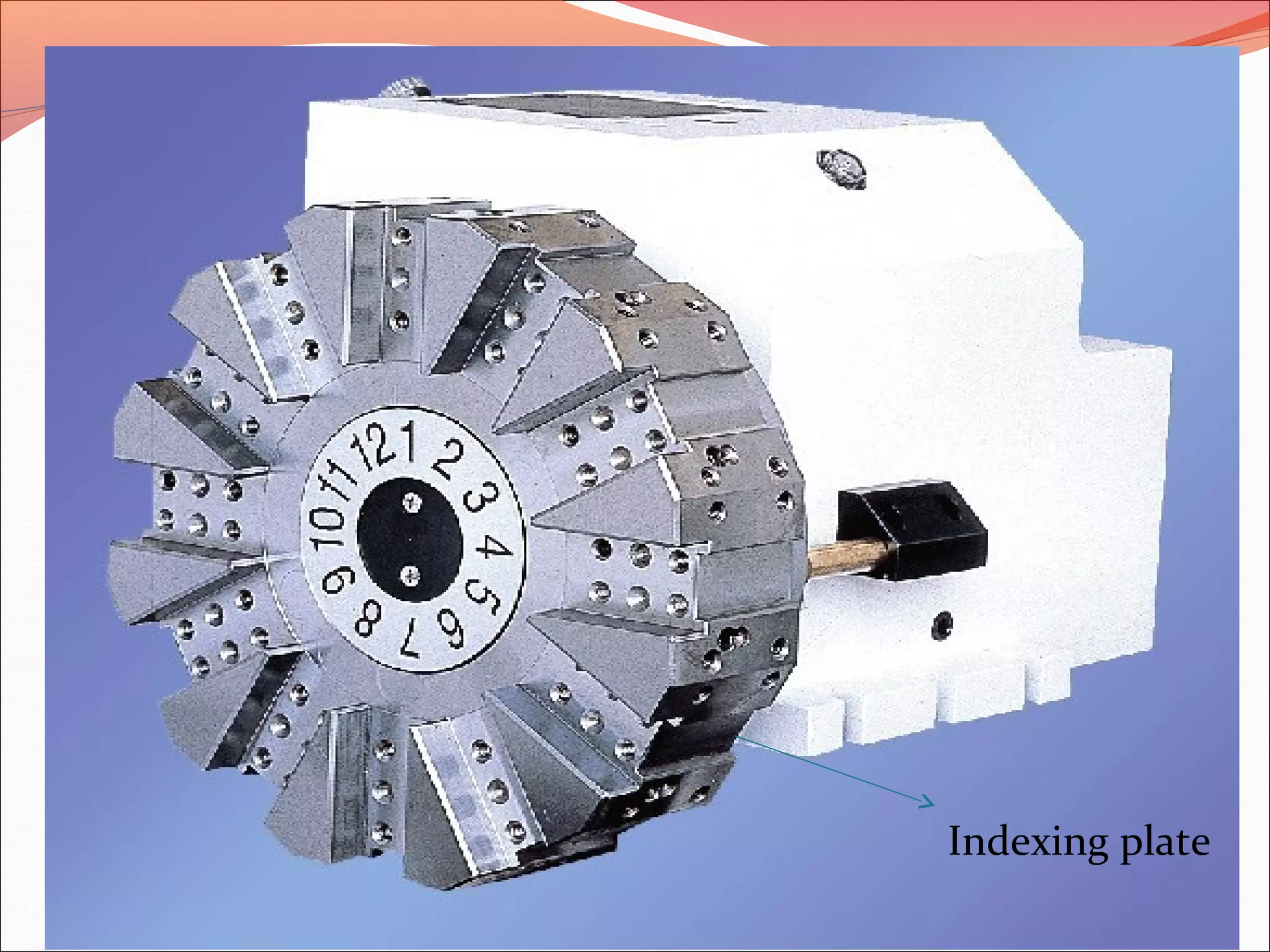

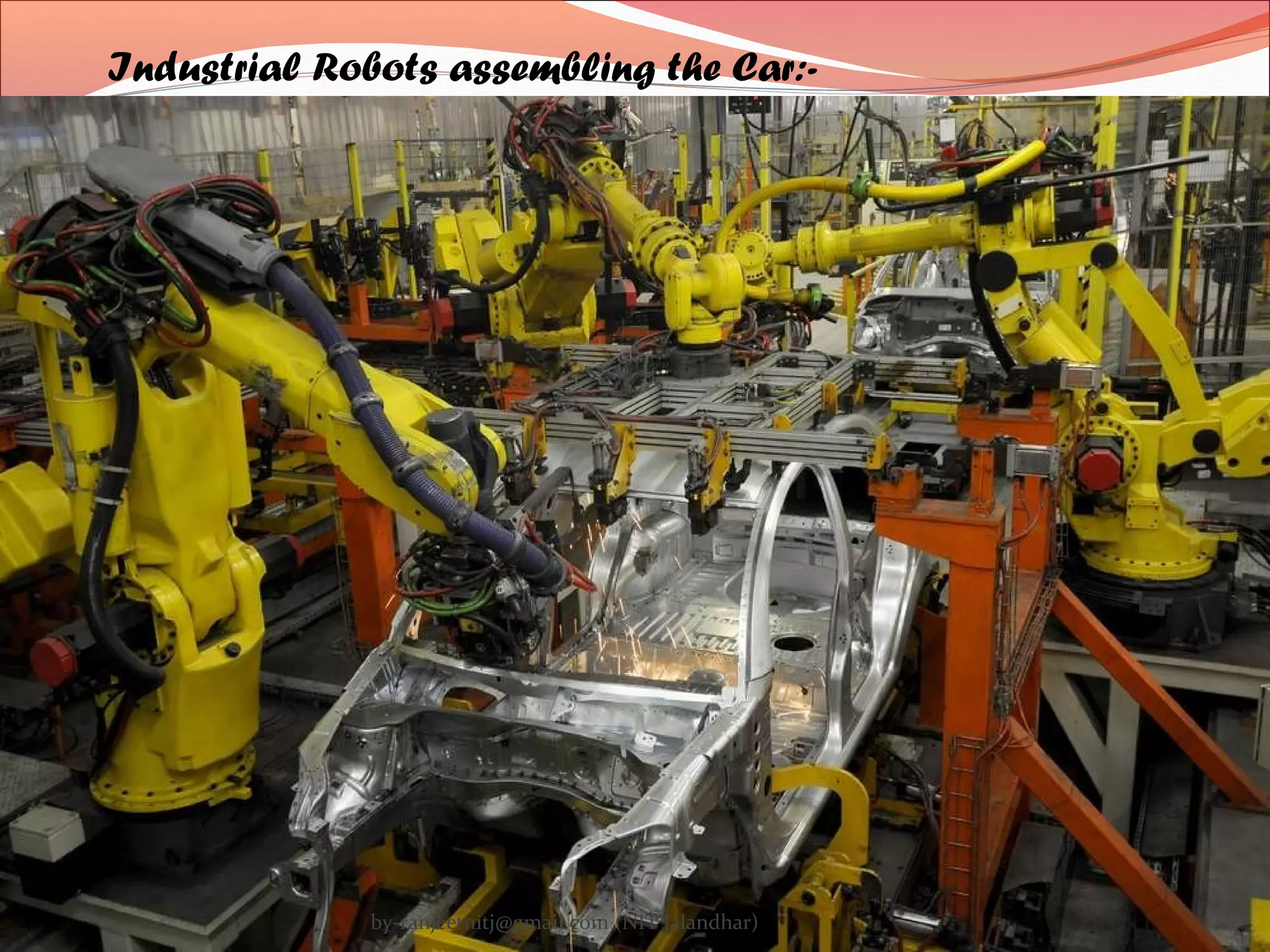

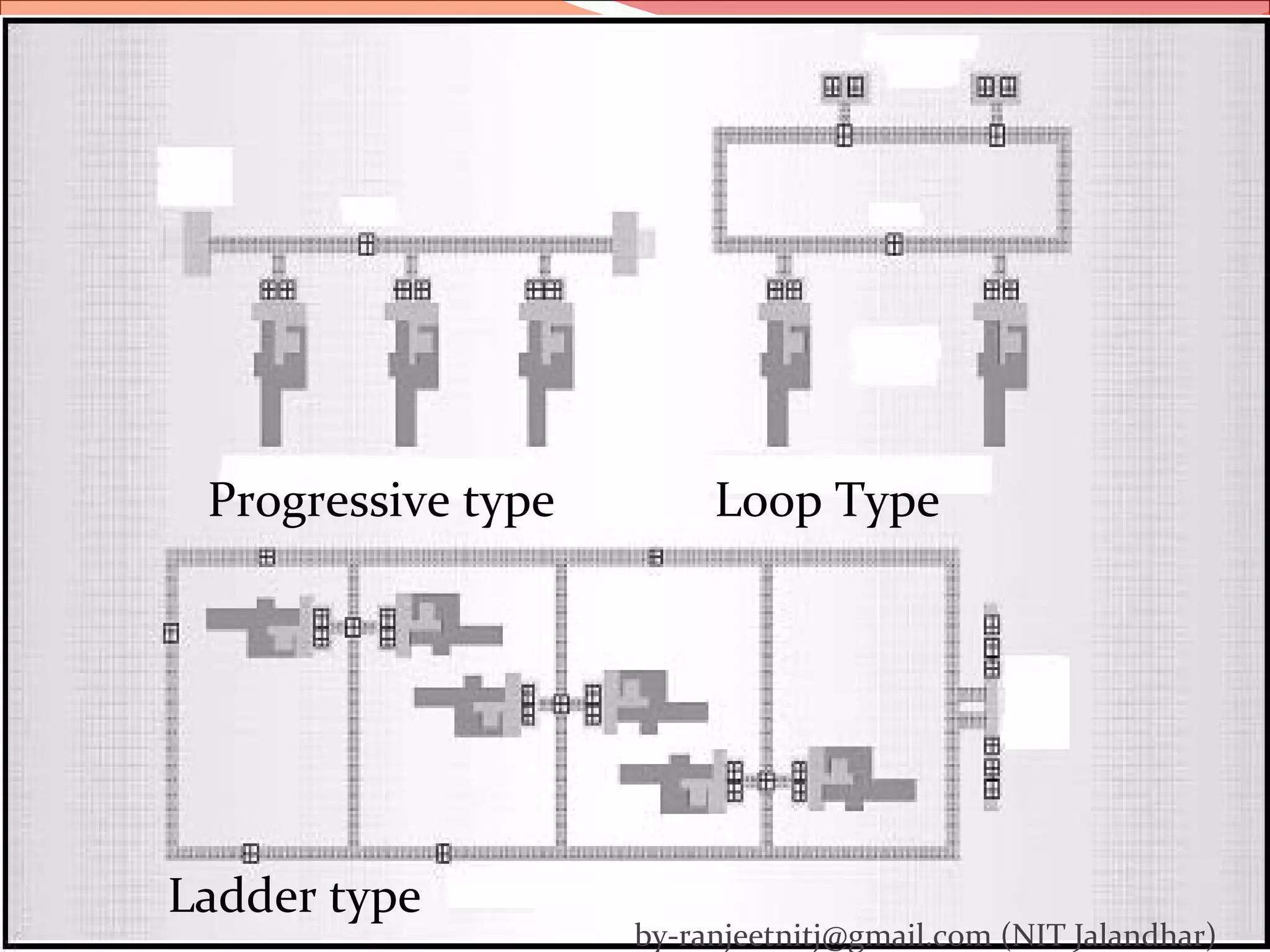

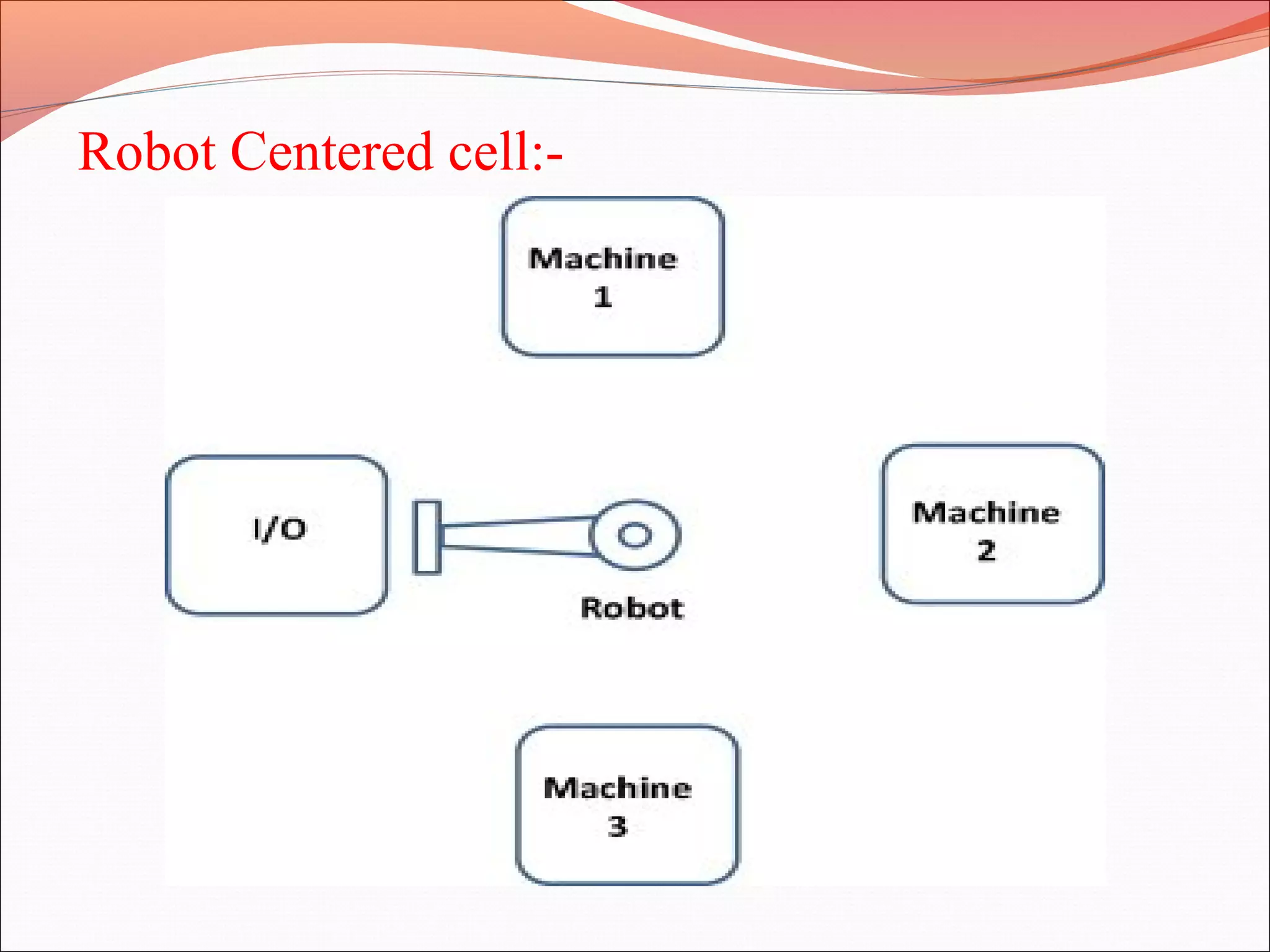

A flexible manufacturing system (FMS) consists of processing stations like CNC machines interconnected by an automated material handling system and controlled by an integrated computer system. It allows for some amount of flexibility in production, including the capability to produce different parts with minimal retooling. The key components of an FMS are workstations, automated material handling using vehicles like AGVs, and a computer control system. FMS layouts can be progressive, loop, ladder, open field, or robot-centered depending on the configuration of the workstations and material flow.