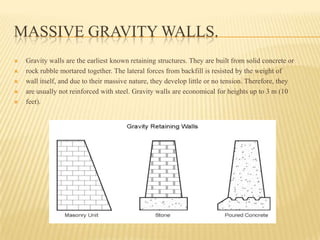

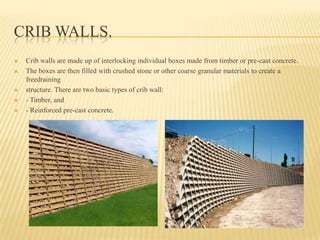

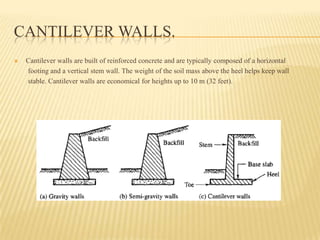

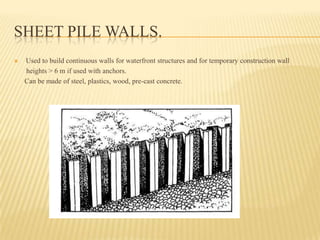

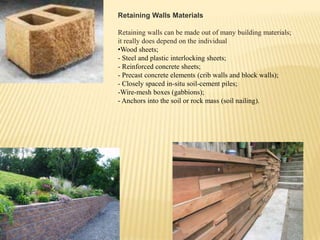

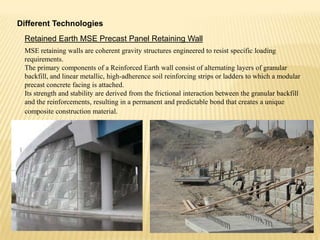

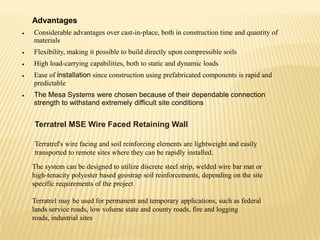

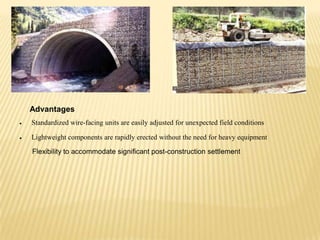

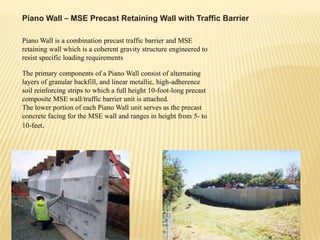

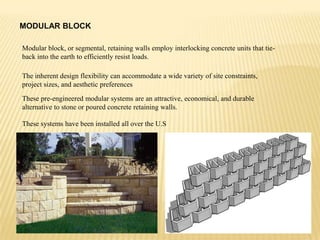

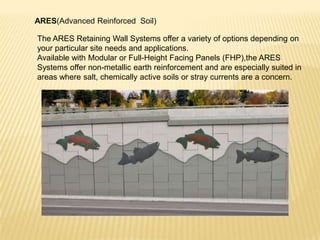

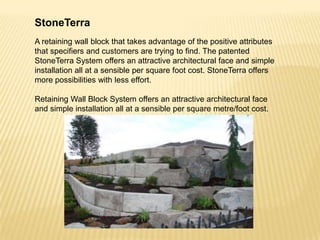

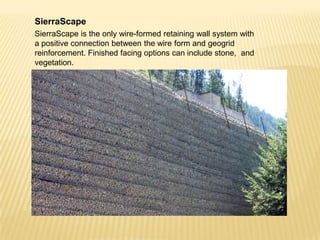

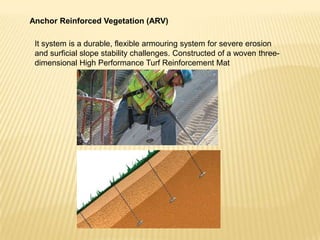

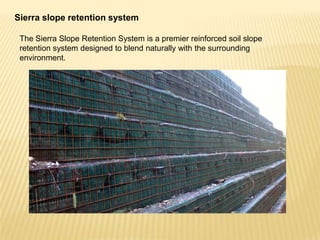

This document provides information on various retaining wall technologies. It discusses gravity walls, crib walls, gabion walls, cantilever walls, sheet pile walls, and types of materials that can be used for retaining walls like wood, steel, concrete. It also summarizes different retaining wall systems like MSE walls, precast panel walls, counterfort walls, modular block walls, and vegetated soil bioengineering systems. The document highlights the advantages of each technology which include fast construction, flexibility, durability, and cost-effectiveness.