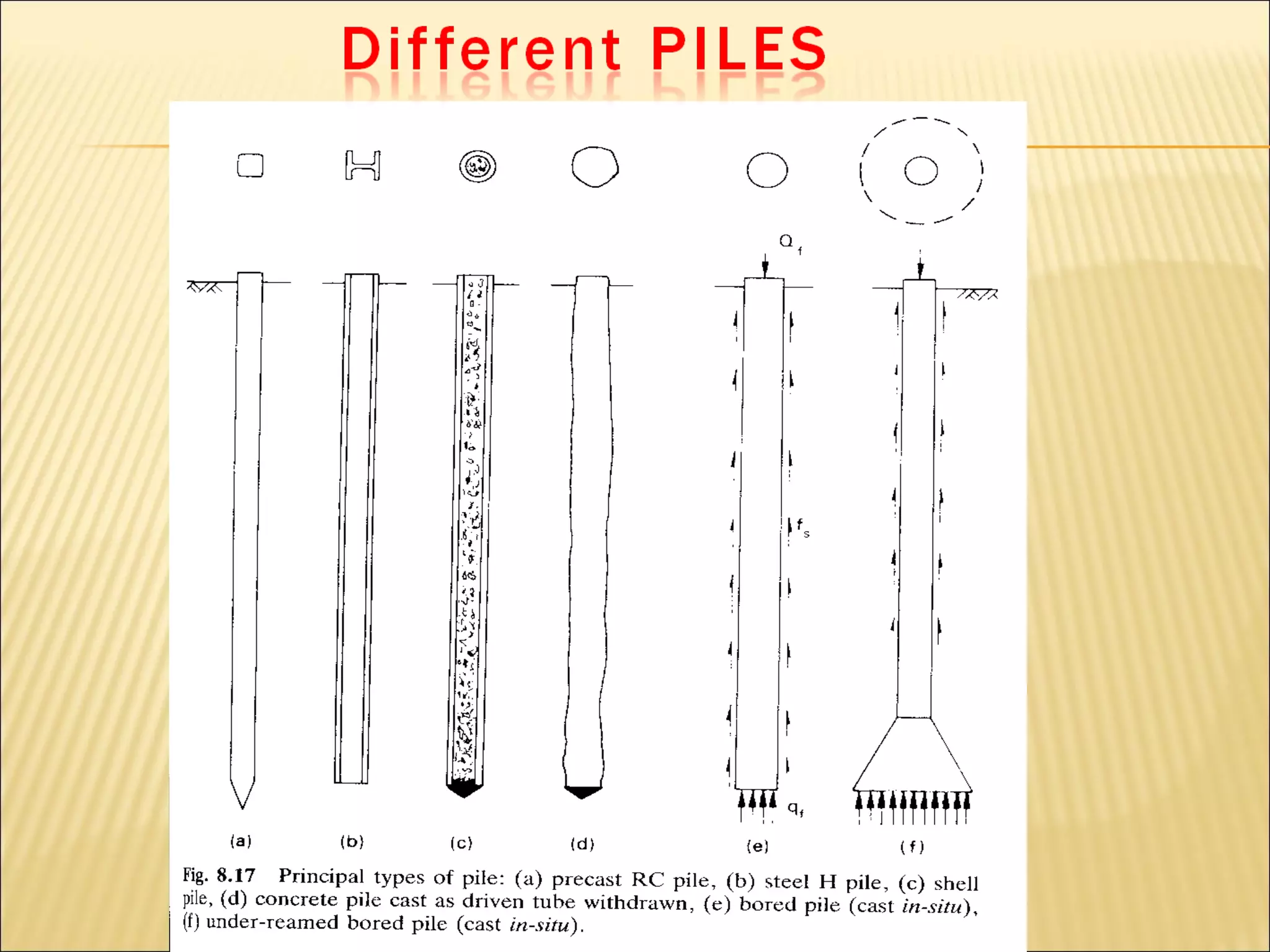

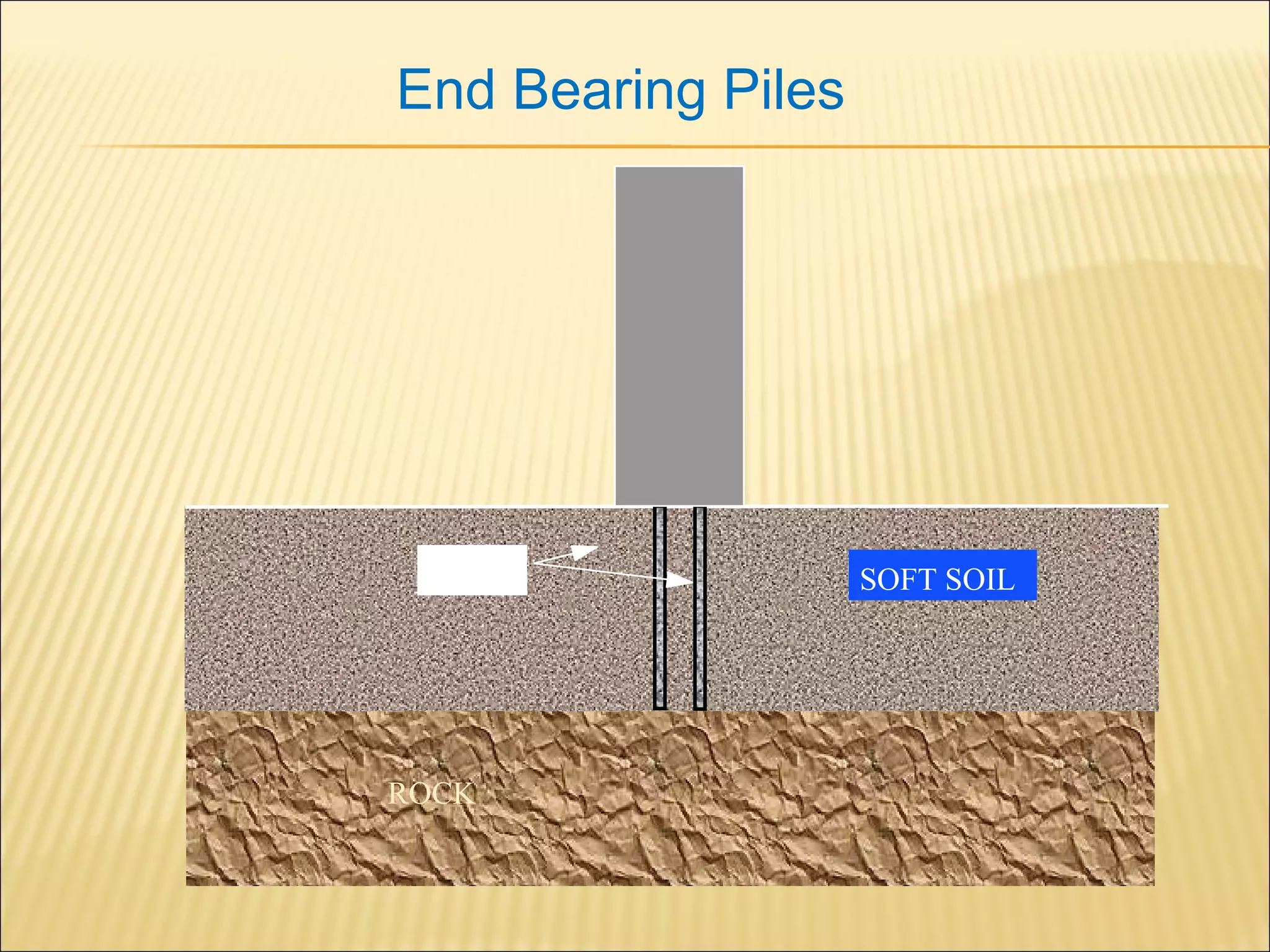

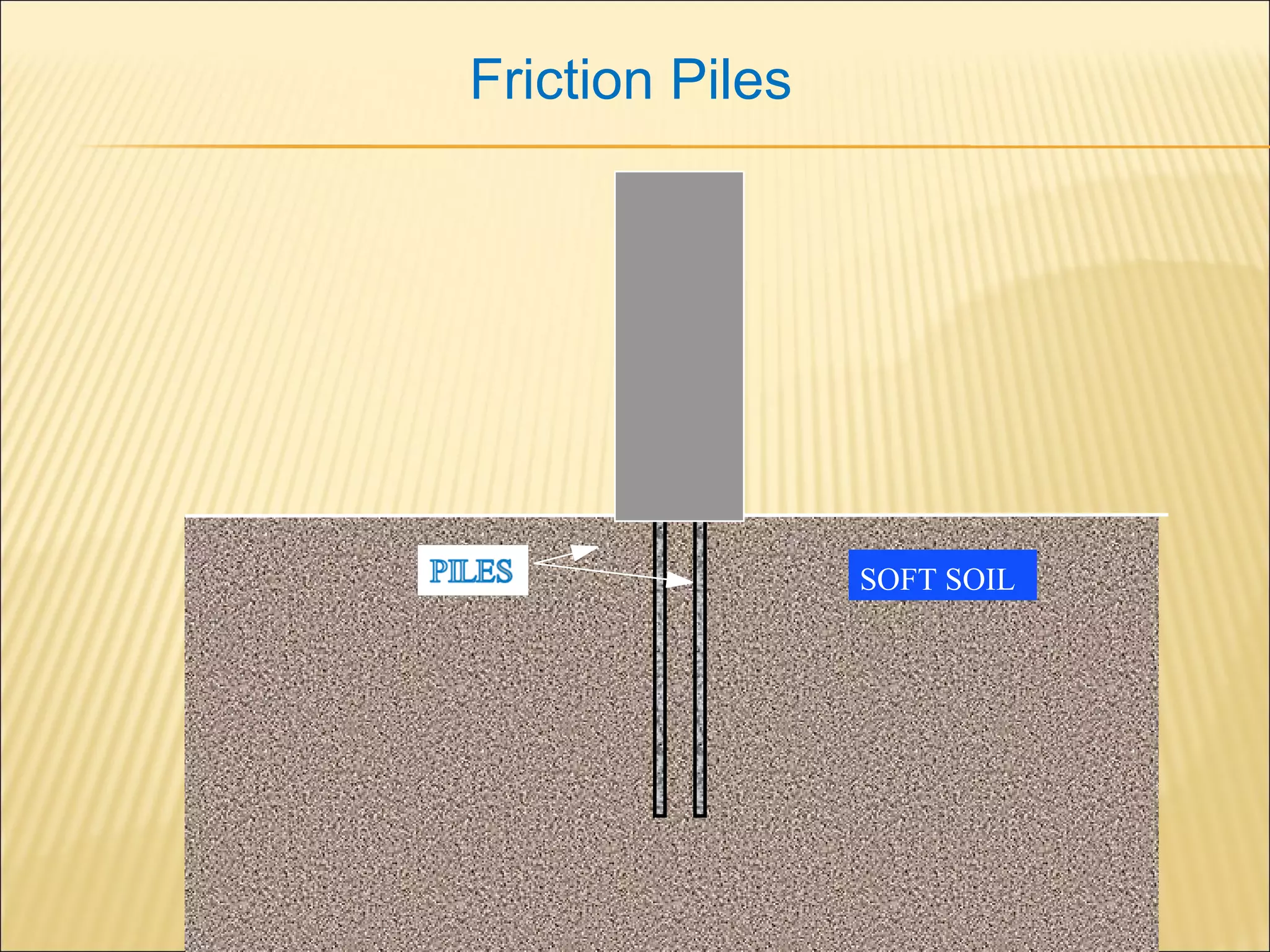

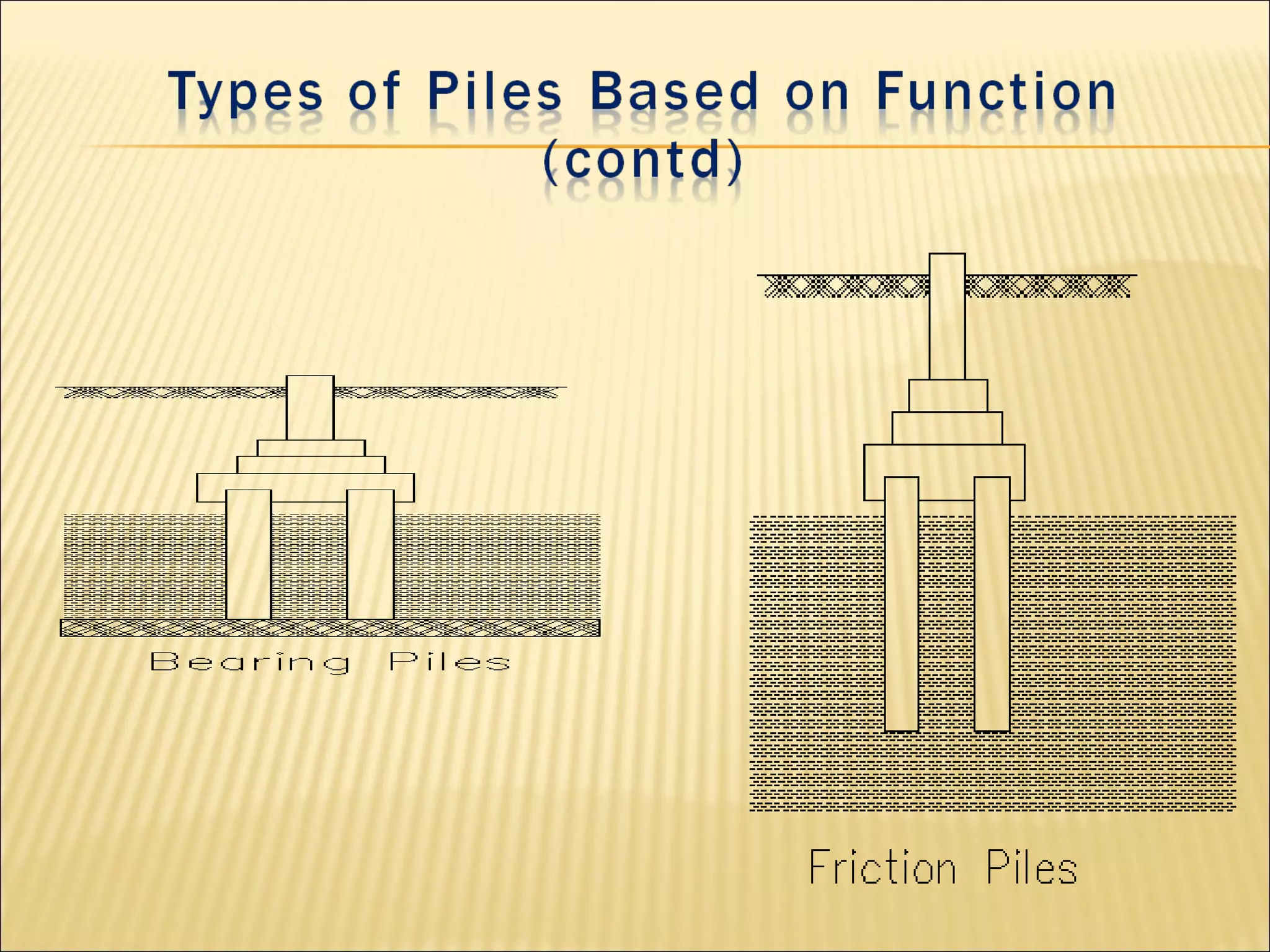

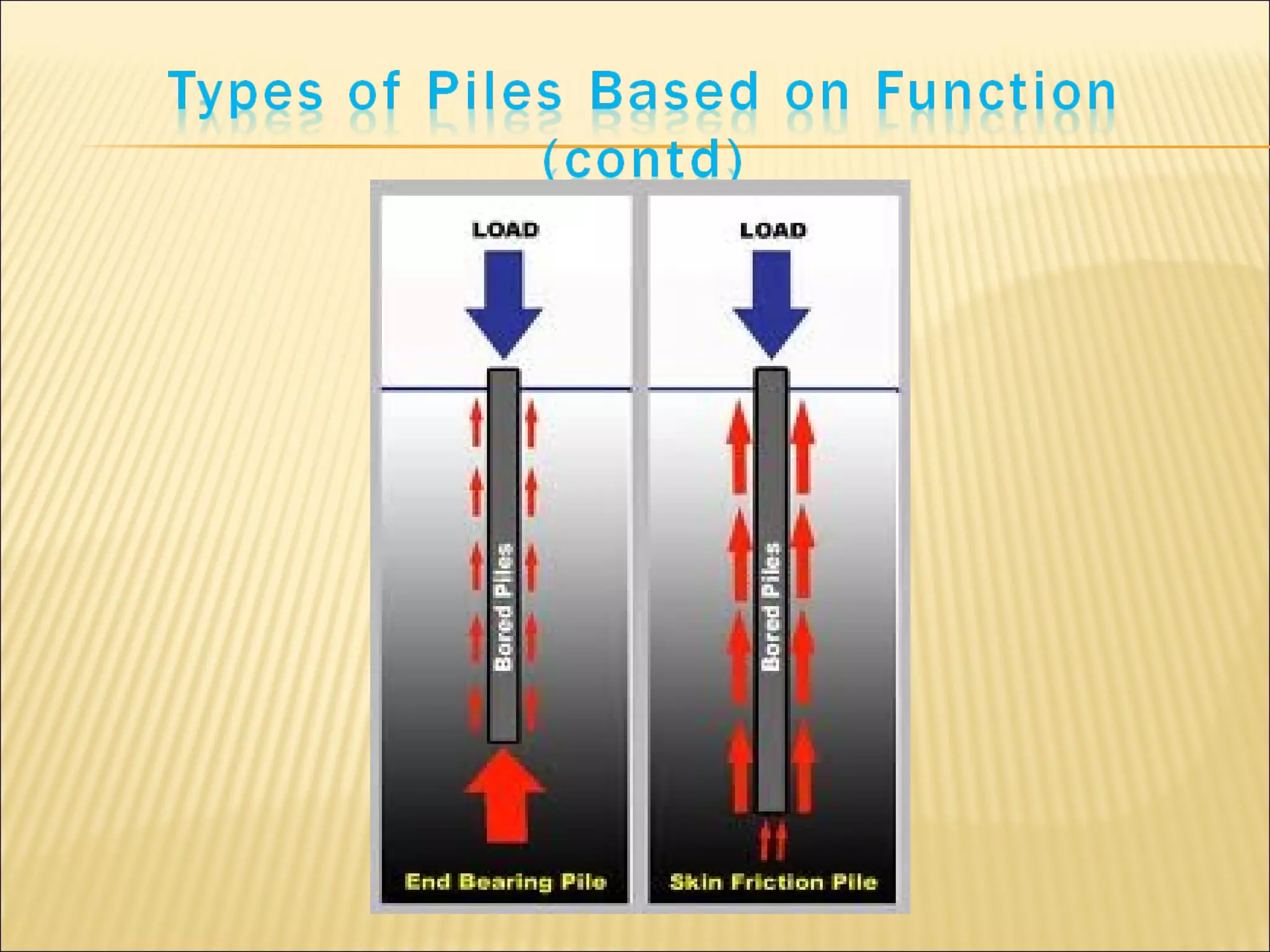

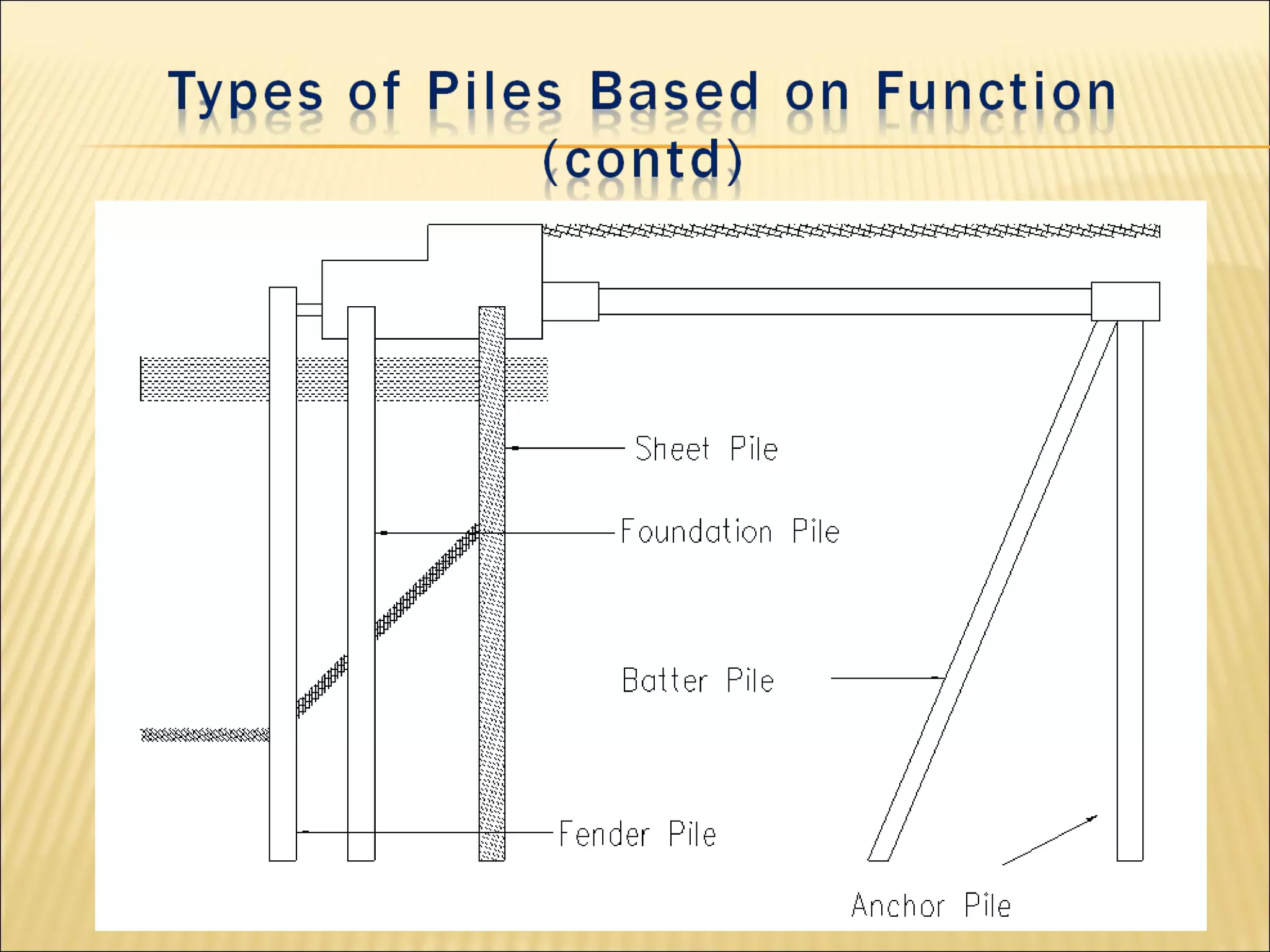

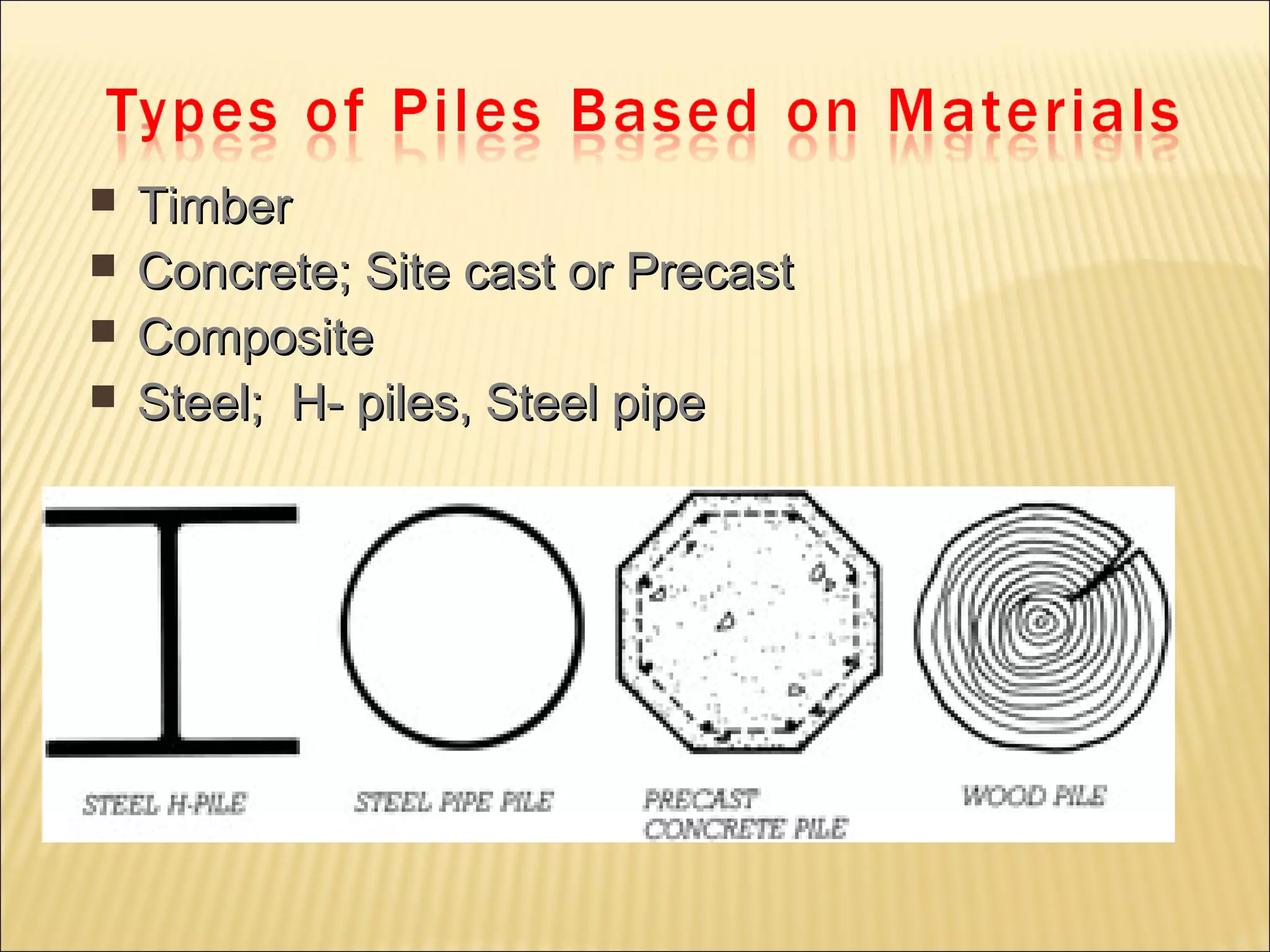

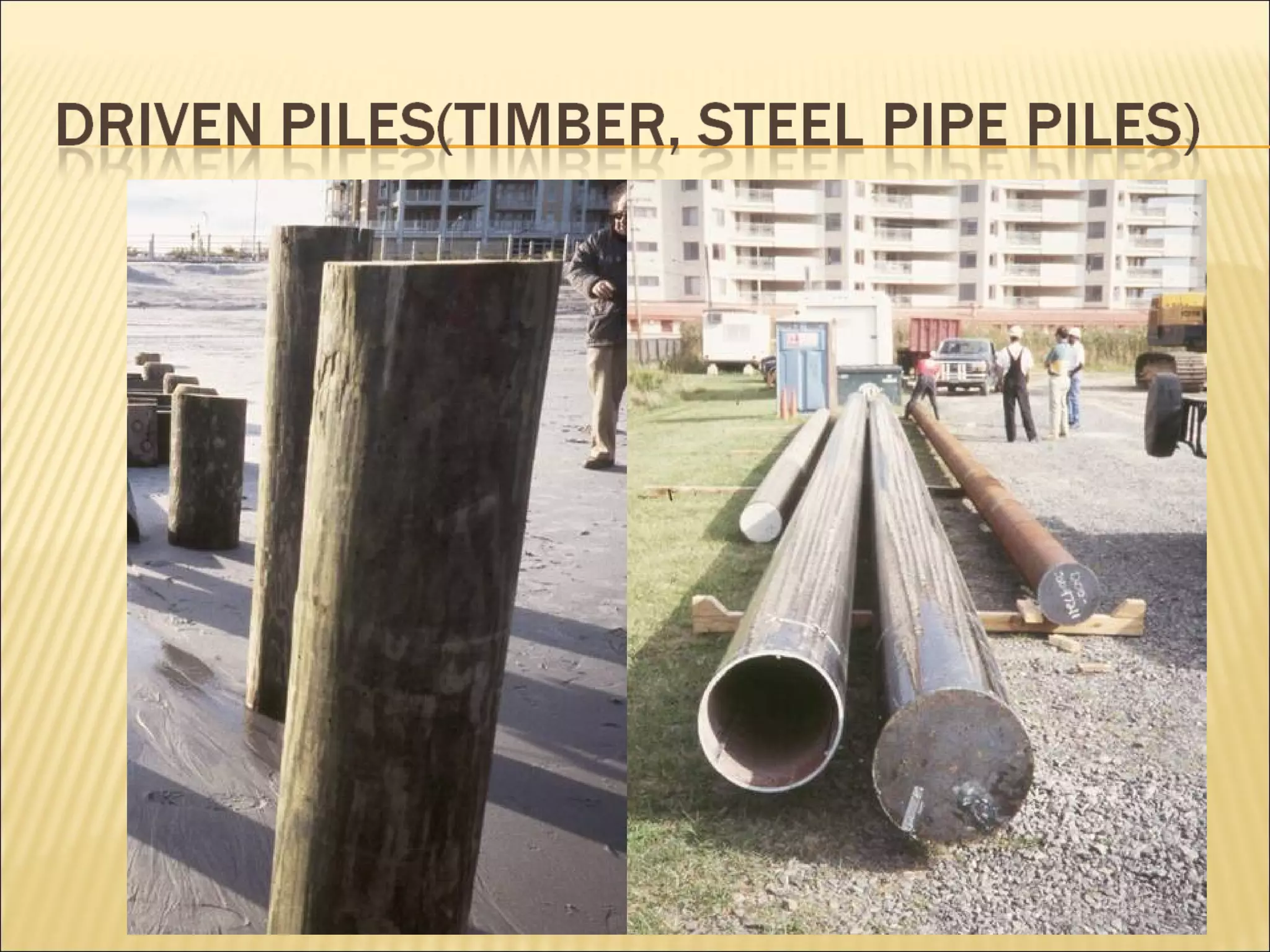

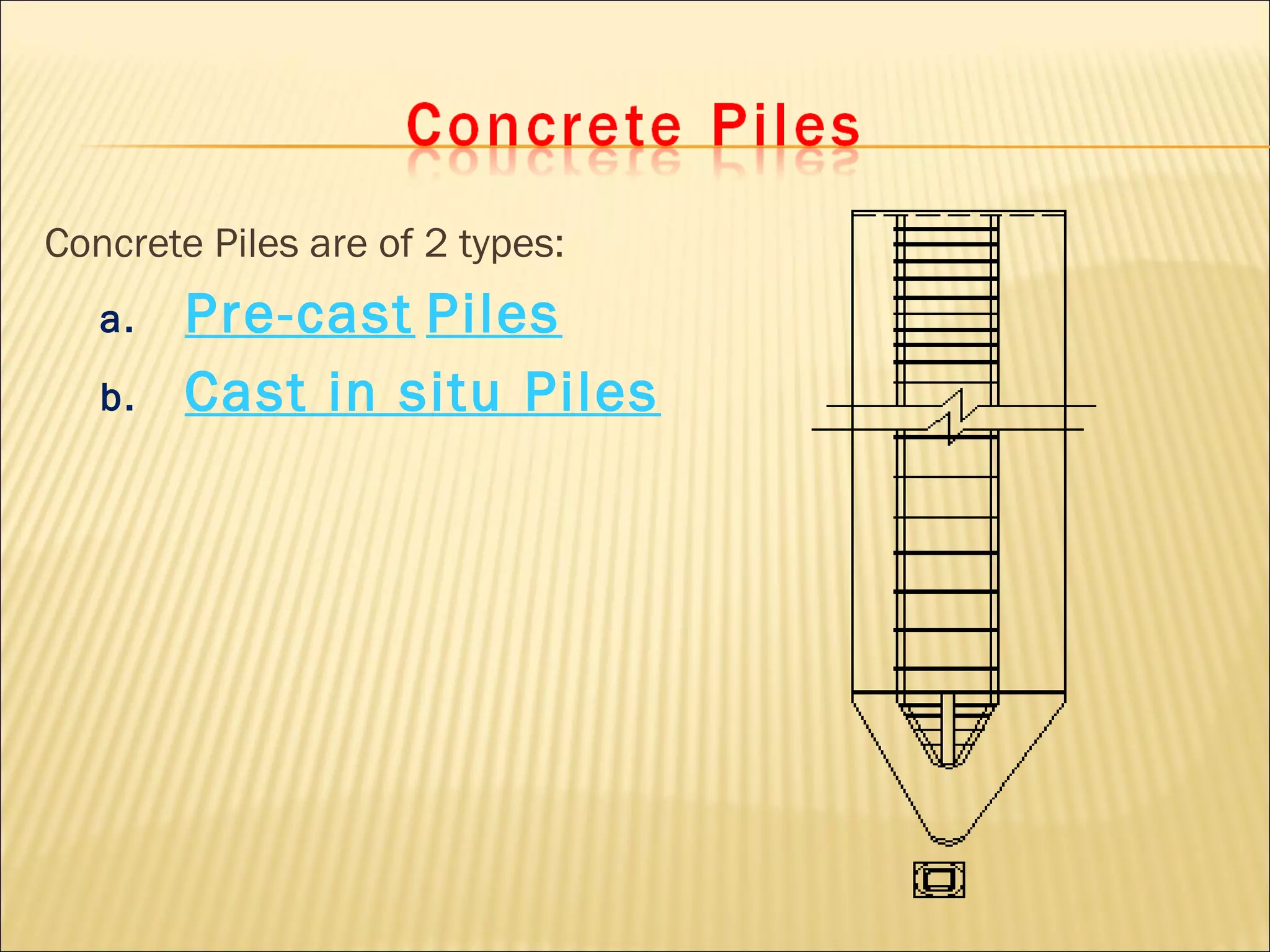

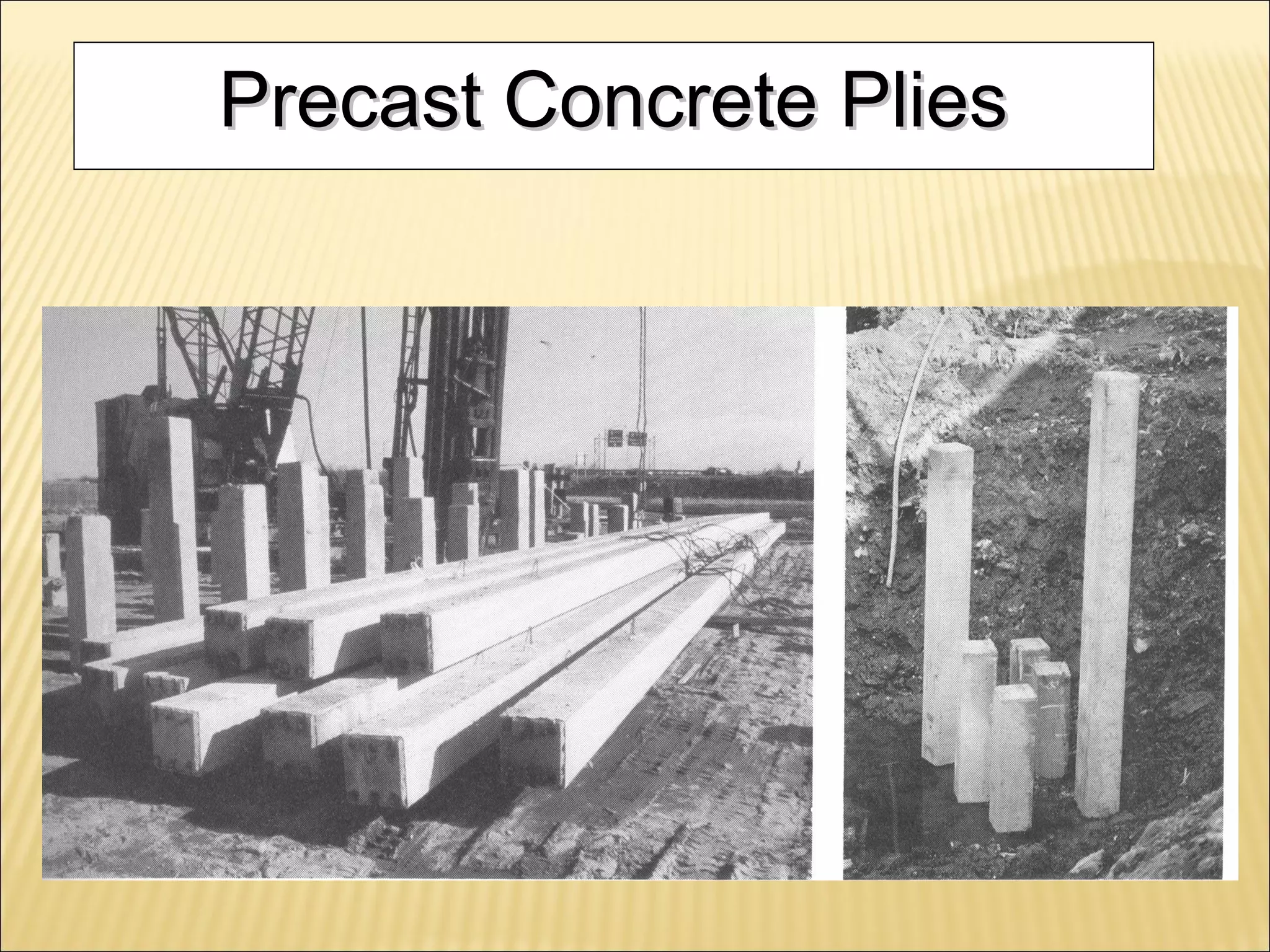

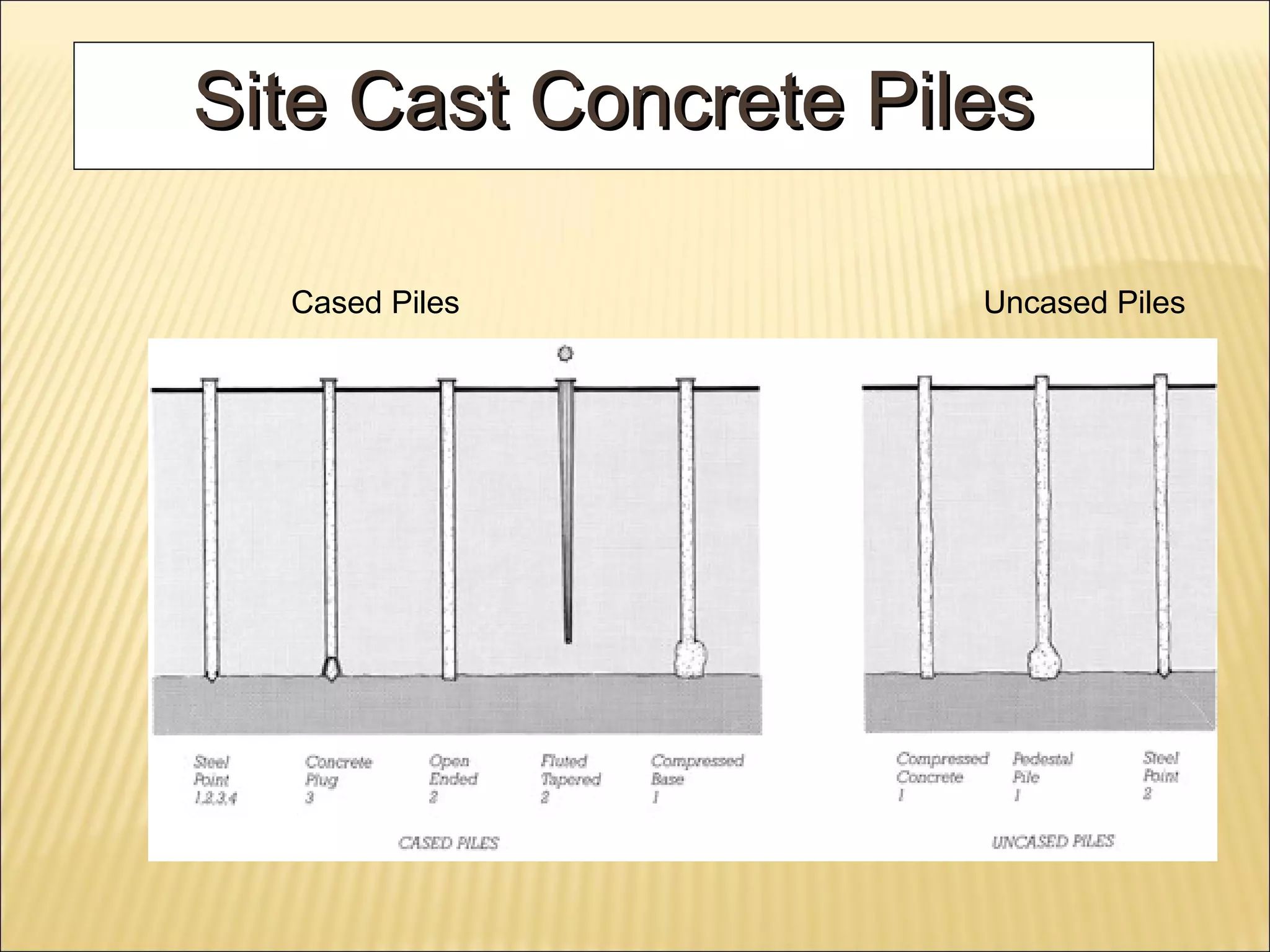

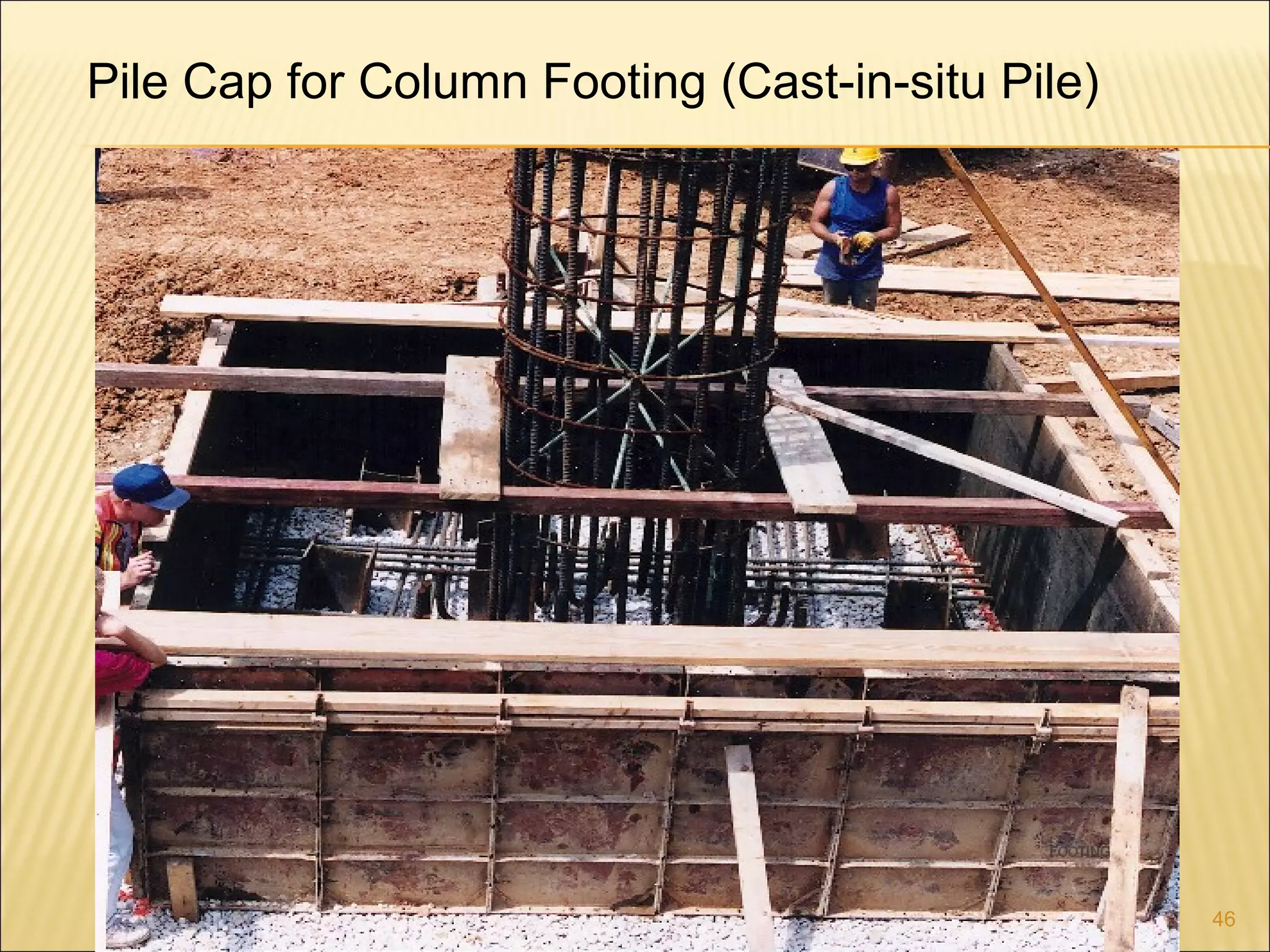

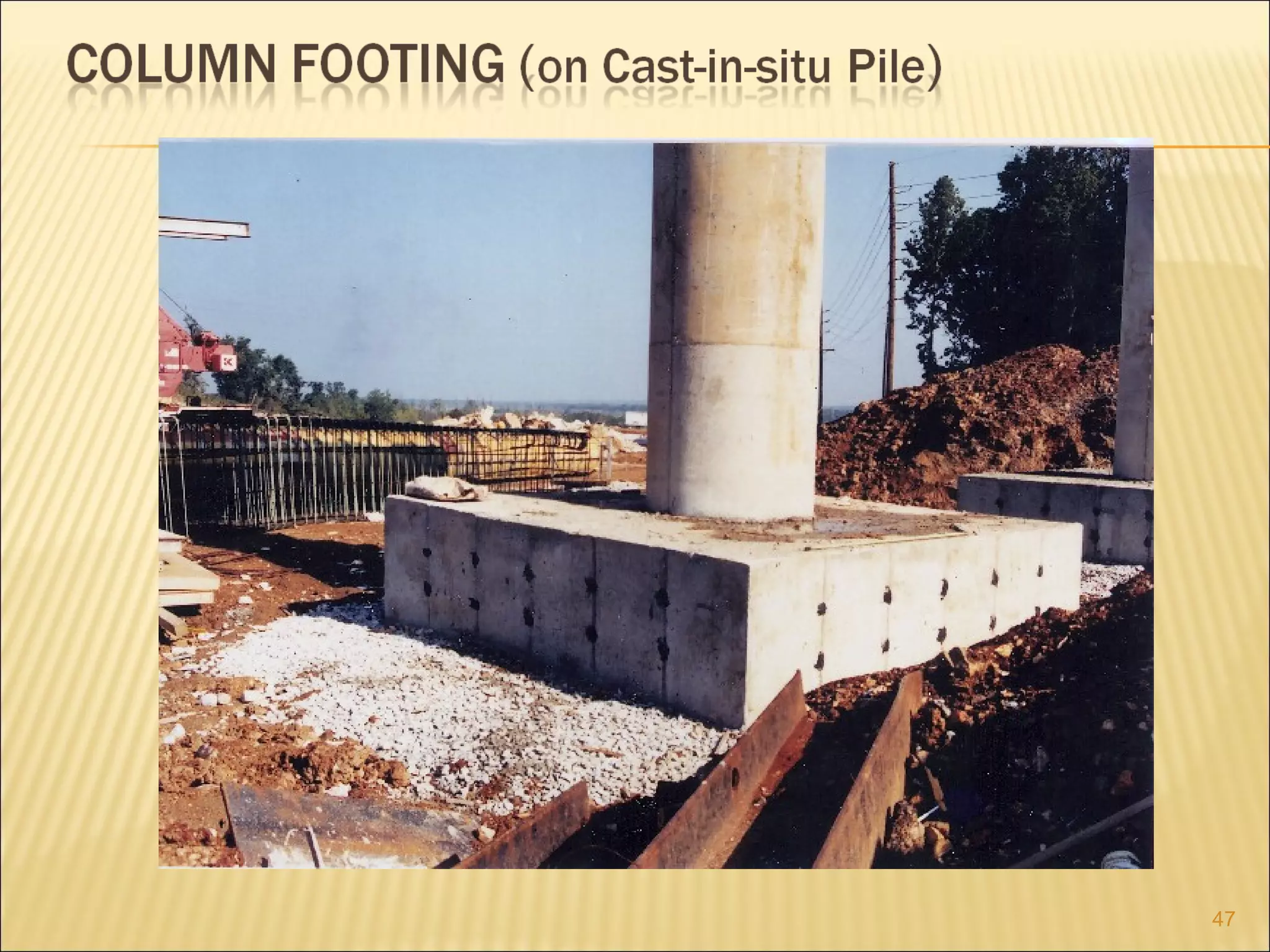

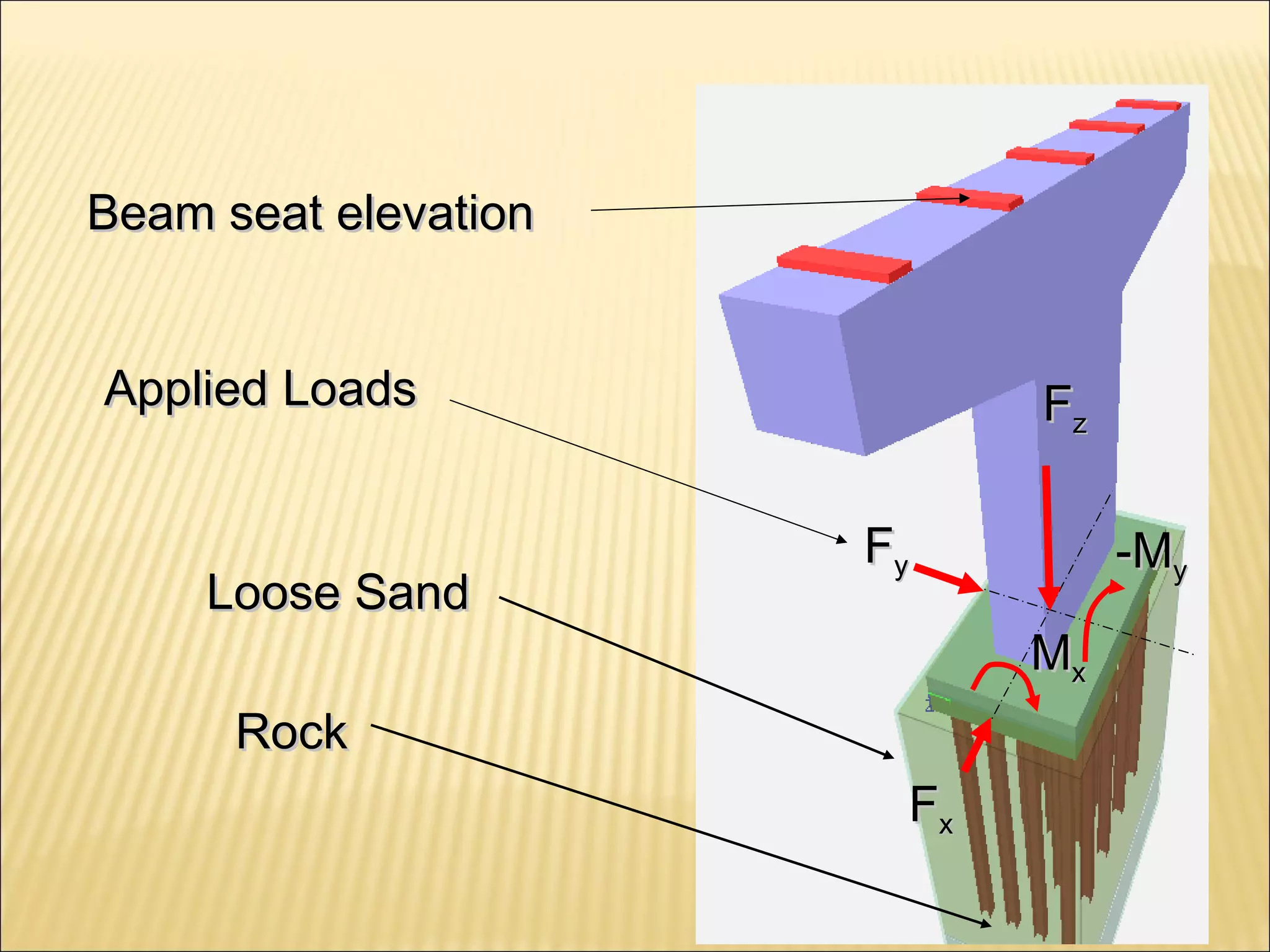

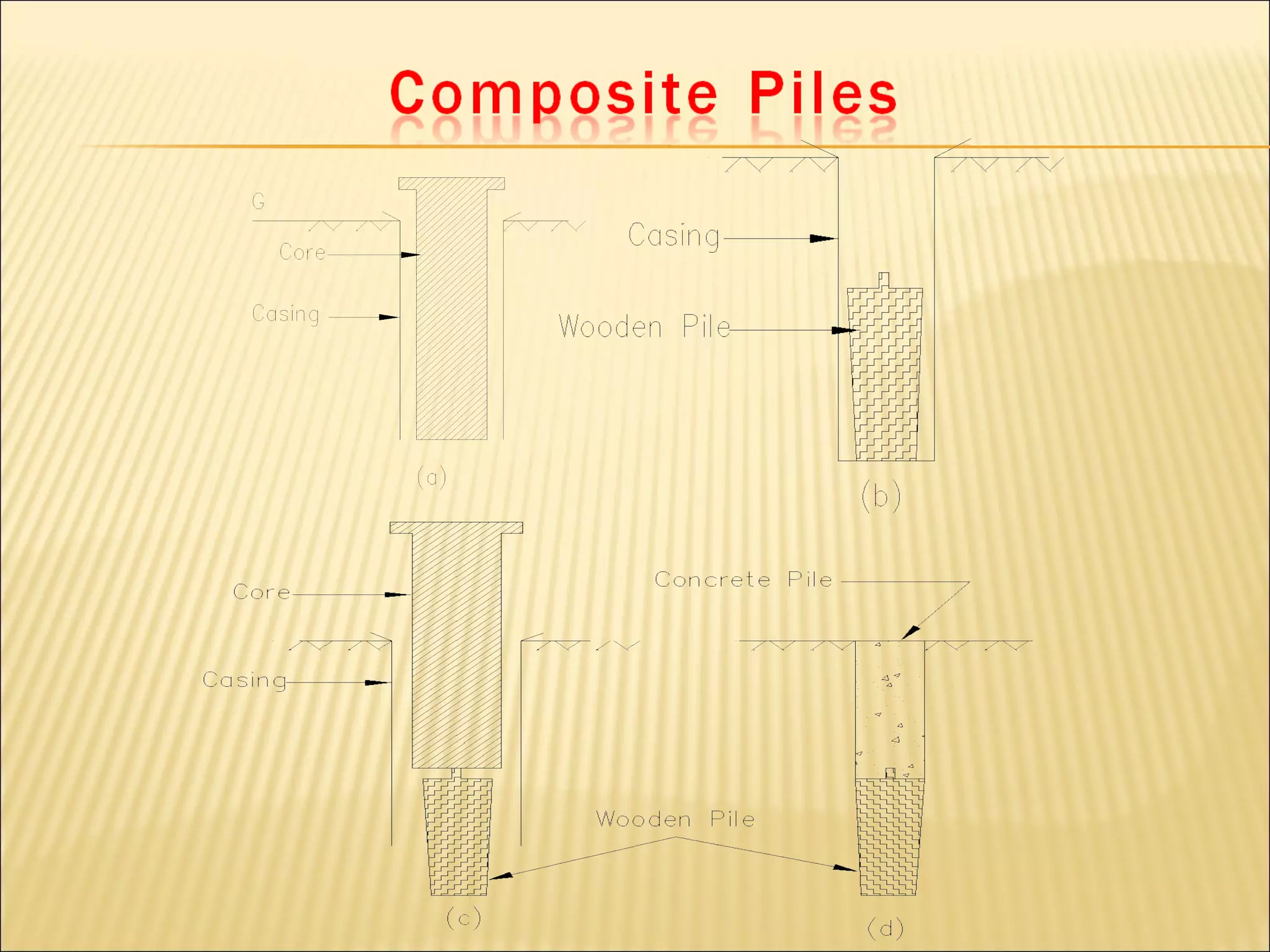

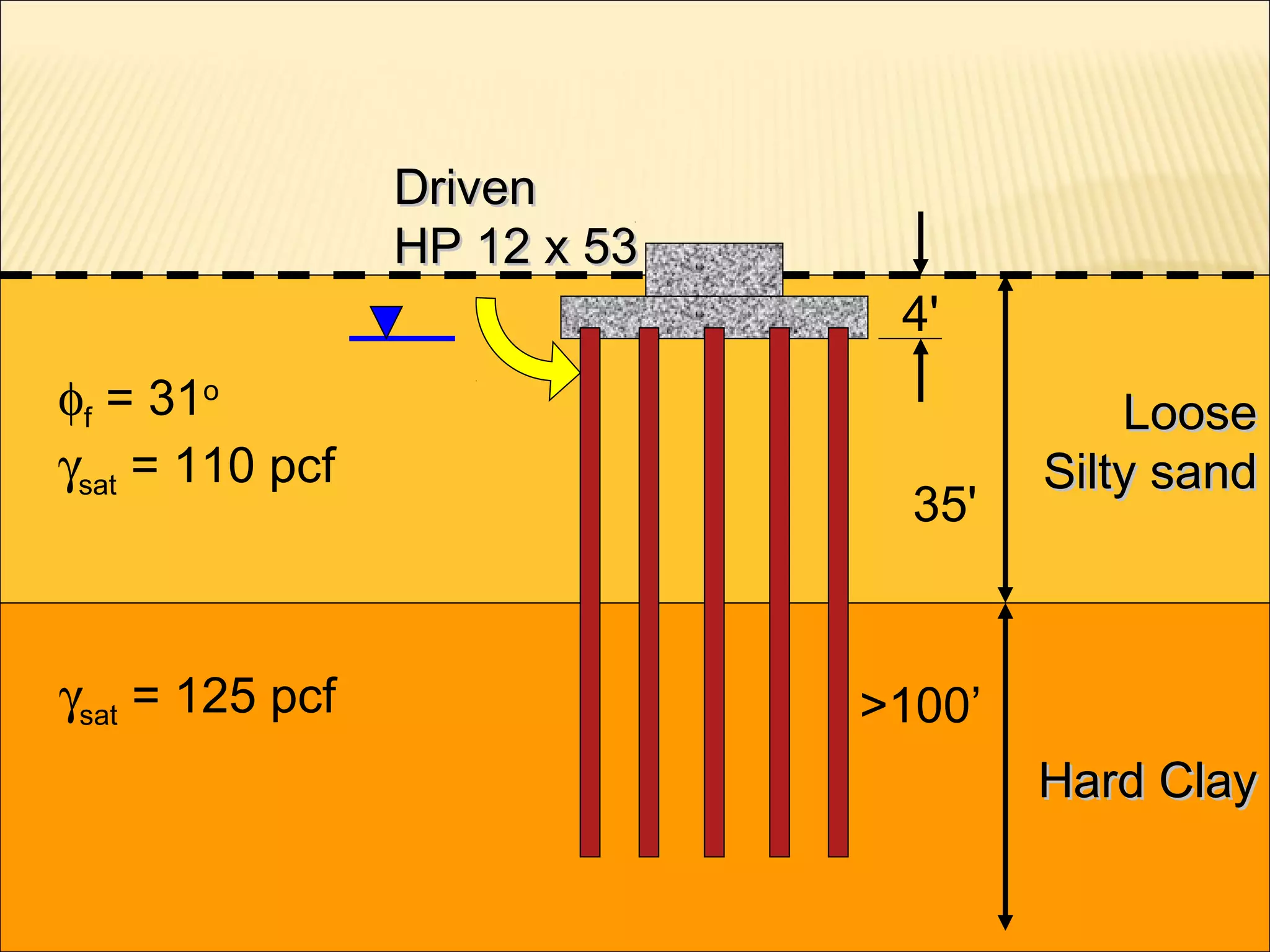

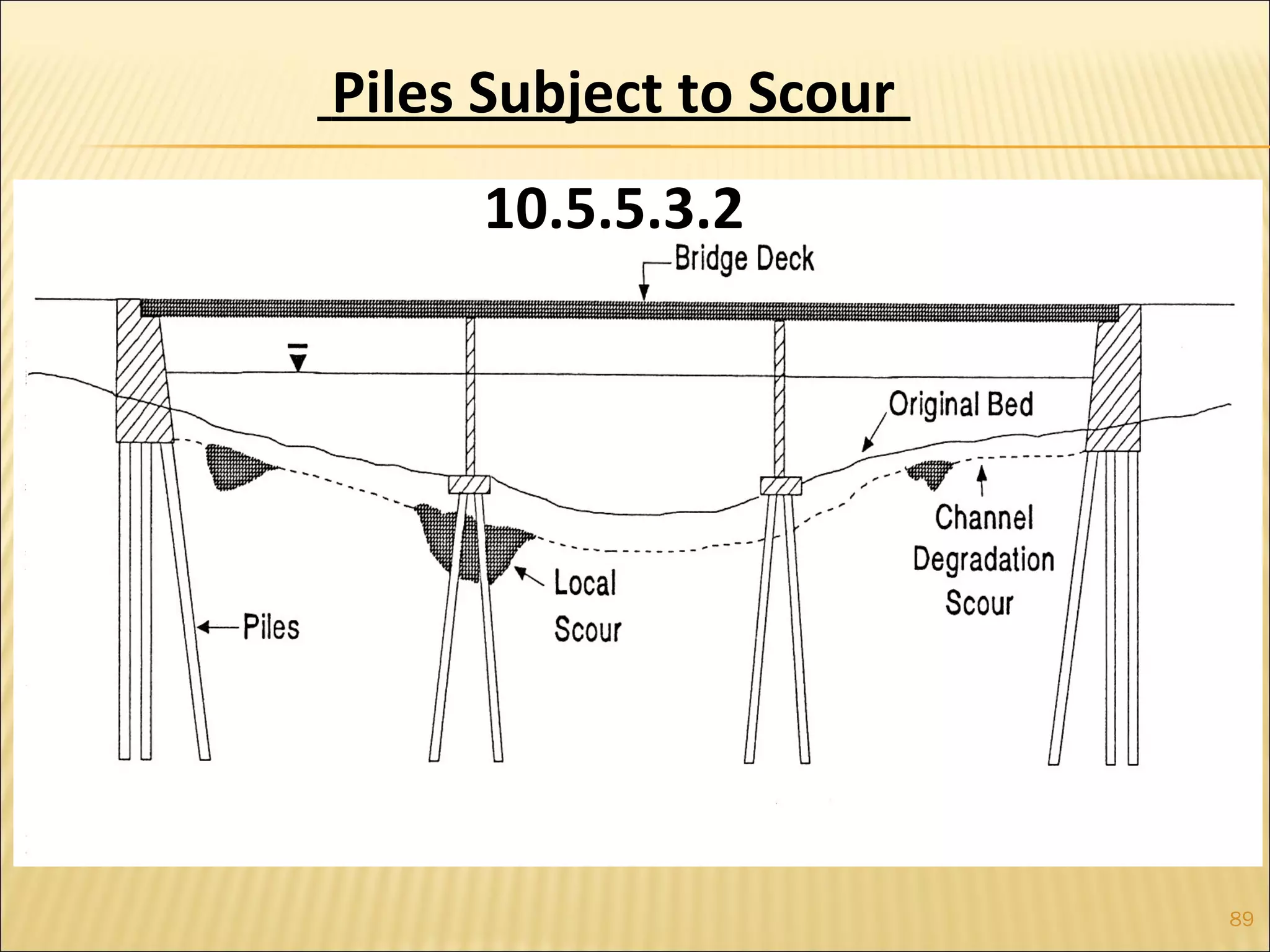

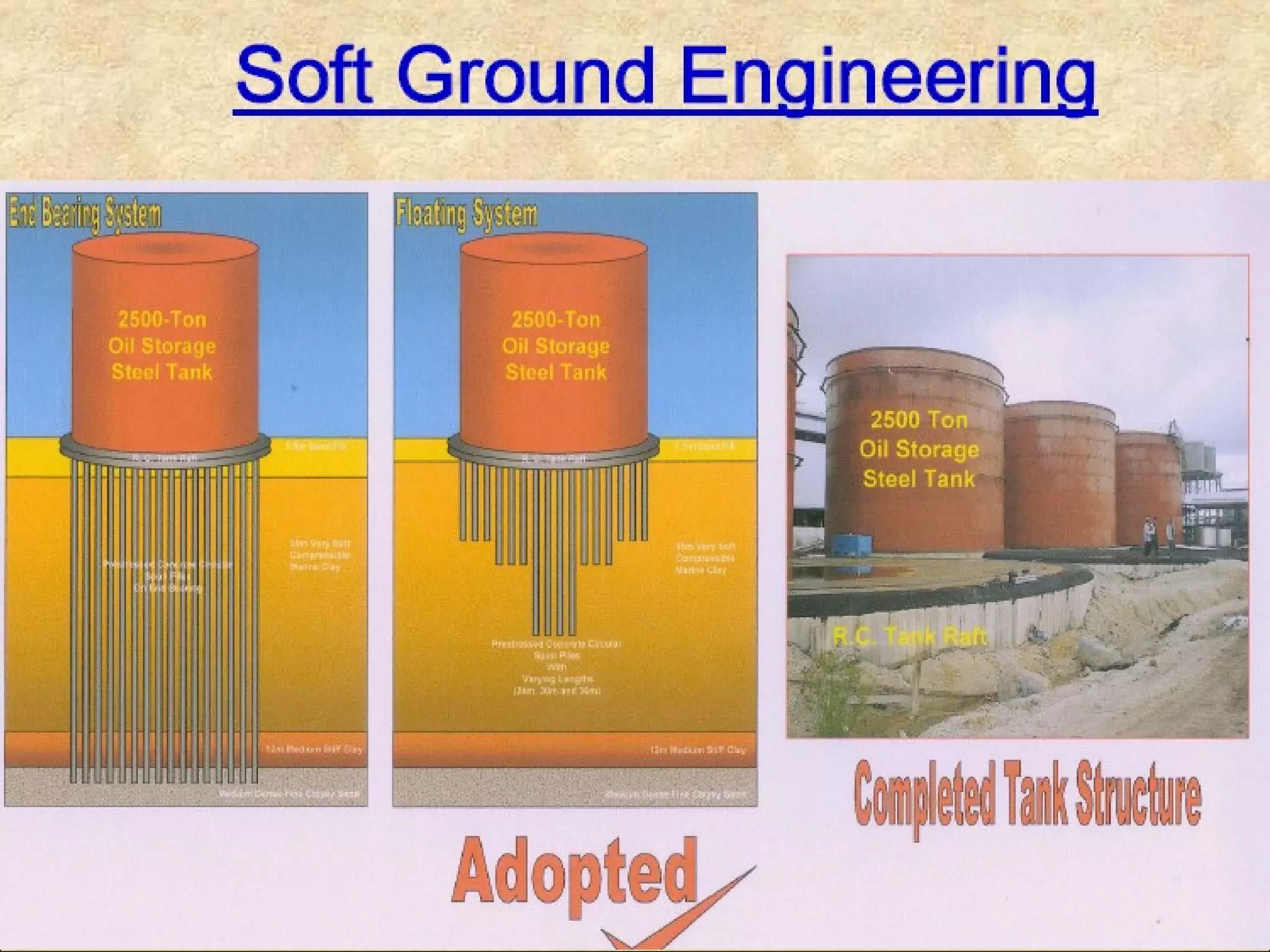

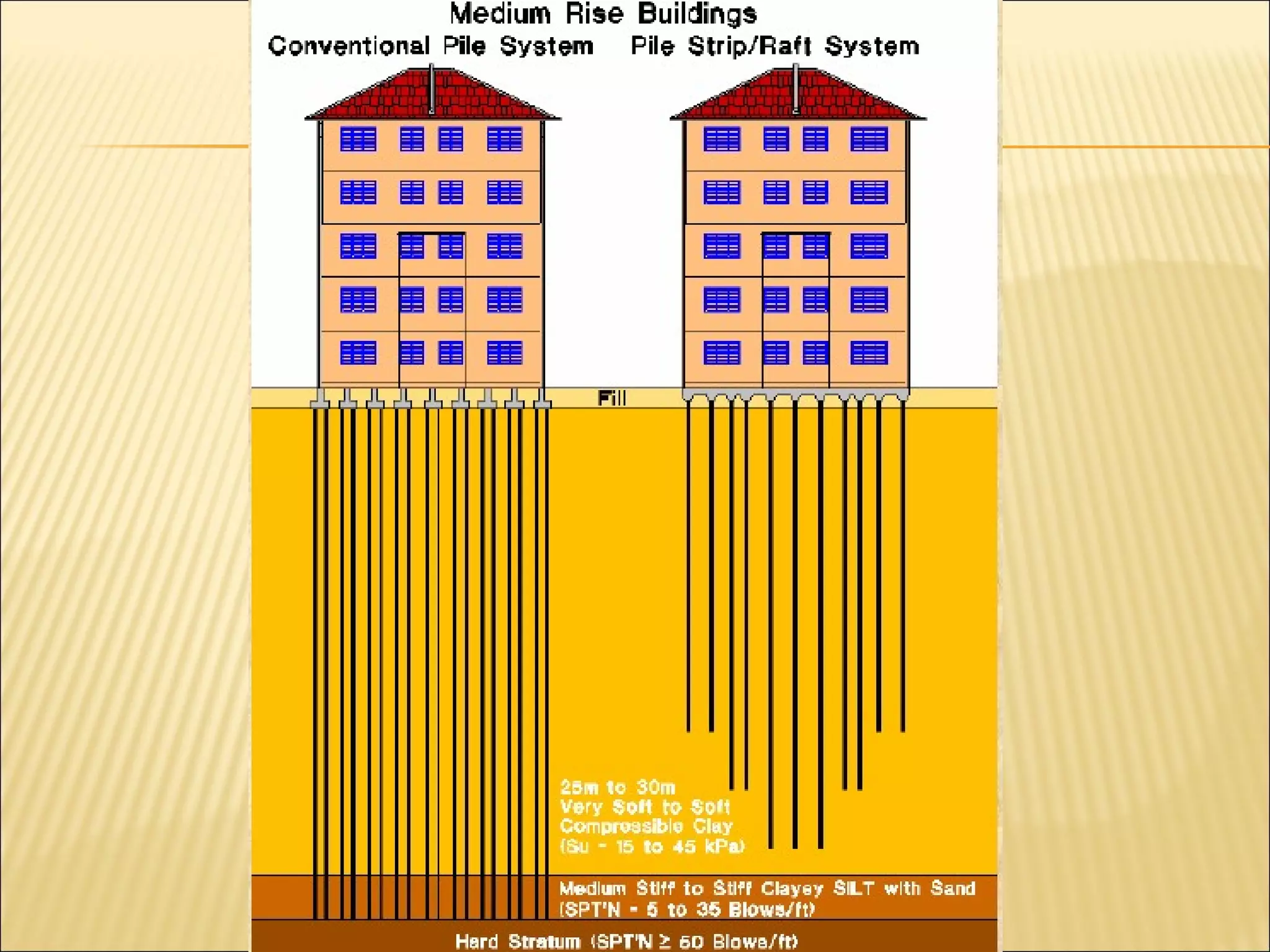

Pile foundations are used when the bearing capacity of soil is low or uneven and the soil is located at a greater depth. Piles transfer structural loads directly to the soil layer below by end bearing or side friction. Common pile types include timber, concrete, steel, and composite piles which are classified based on function, material, and installation method. Pile foundations provide solutions for difficult soil conditions like compressible, waterlogged, or made ground and are widely used for bridges, buildings, and marine structures.