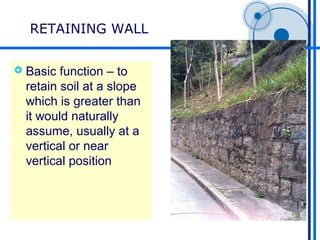

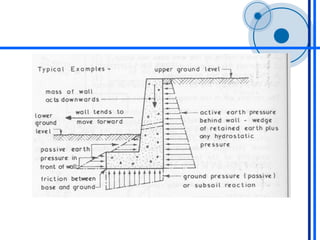

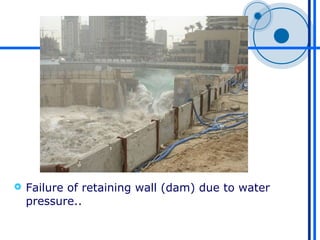

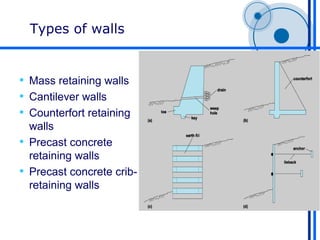

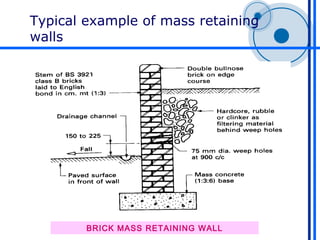

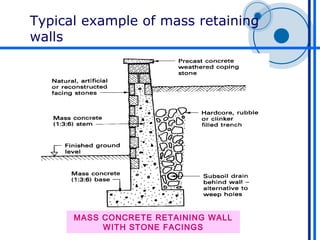

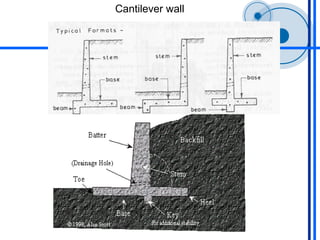

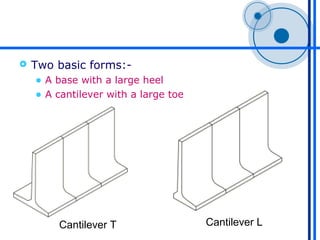

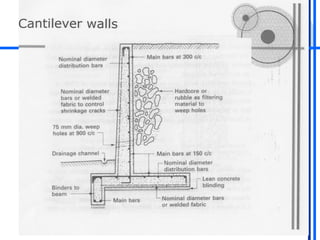

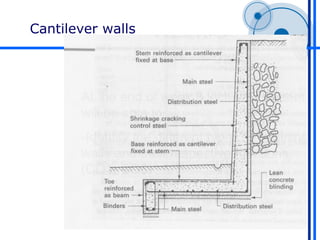

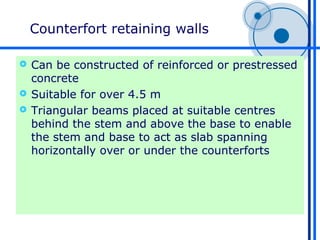

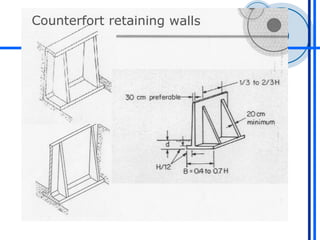

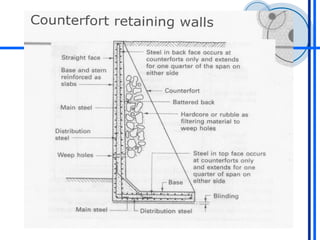

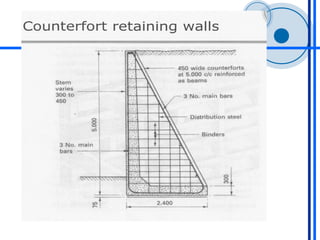

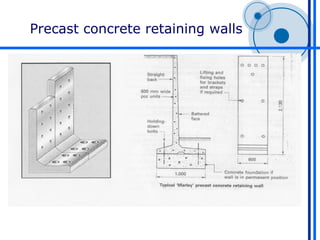

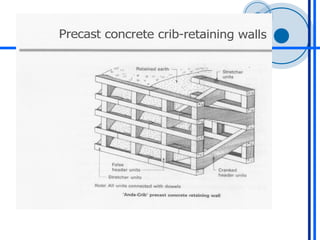

Retaining walls are designed to retain soil at an angle greater than its natural slope, usually in a near-vertical position. They work by either their own mass or through leverage to prevent overturning, sliding, or soil overload. Design considerations include the subsoil type and water table level, as they can impact bearing capacity and hydrostatic pressure. Common wall types are gravity, cantilever, counterfort, precast concrete, and precast crib walls. Proper design is needed to ensure stability based on the wall height, materials, and subsurface conditions.