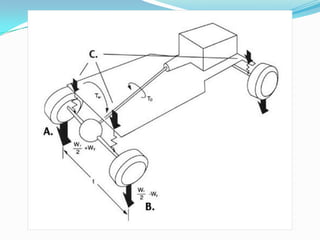

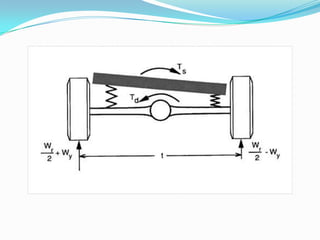

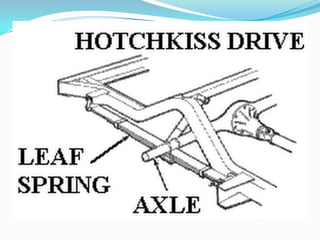

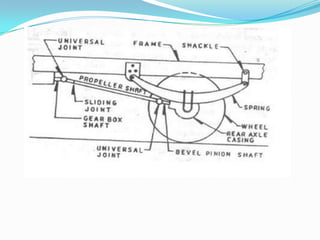

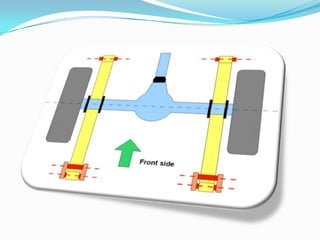

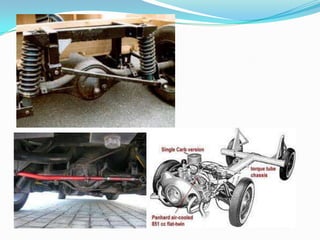

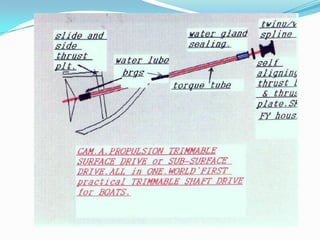

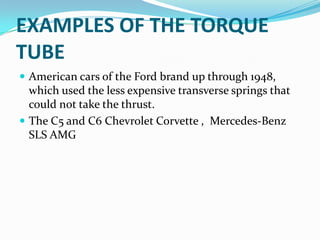

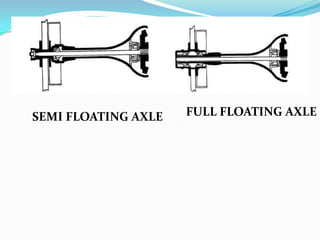

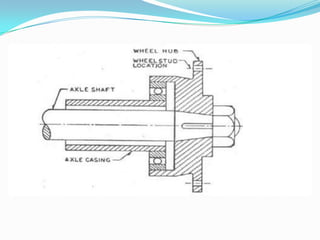

The document provides information on rear axle drives and rear axle shafts. It discusses the Hotchkiss drive system which uses leaf springs to locate the rear axle and transmit driving forces. It is a simple and inexpensive design. The document also describes torque tube drives and compares them to Hotchkiss drives. Finally, it discusses different types of rear axle shafts including semi-floating, full-floating, and three-quarter floating axles.