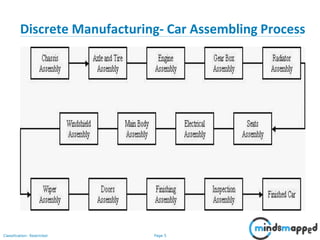

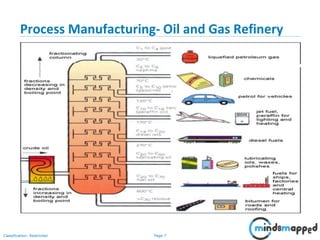

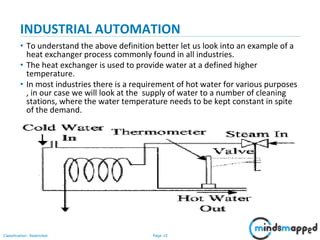

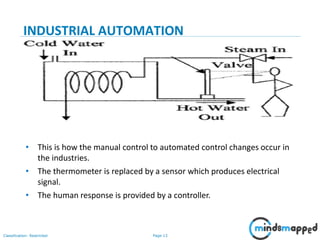

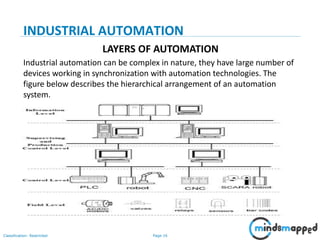

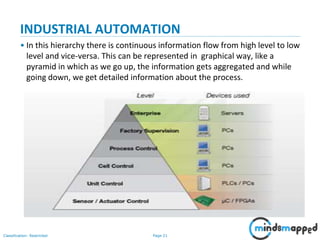

This document provides an overview of industrial automation and control systems. It begins with an agenda that covers industries and classifications, introduction to industrial automation, and examples of process and discrete manufacturing. It then defines process and discrete industries, and provides examples of a car assembly line and oil refinery. The document introduces industrial automation as using technology and automatic controls to operate industrial processes without human intervention. It covers the advantages of automation including higher productivity, quality and safety. Finally, it describes the layers of an automation system including the field, control, supervisory and production, and information levels.