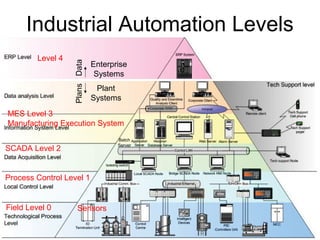

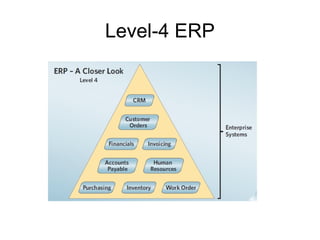

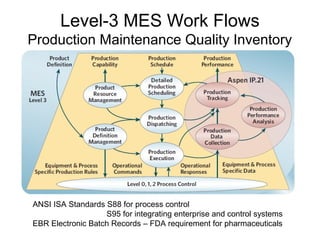

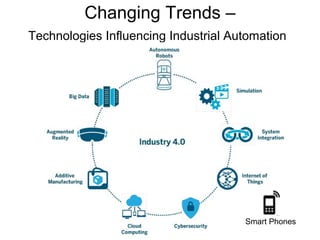

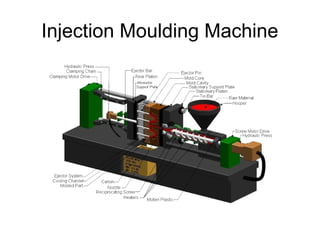

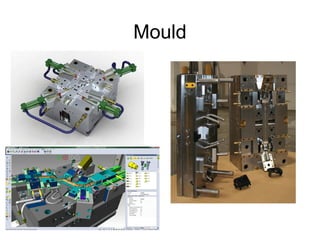

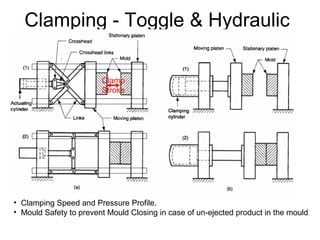

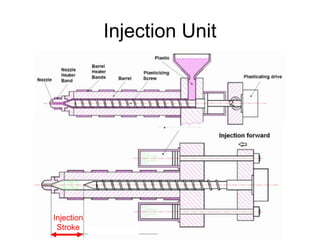

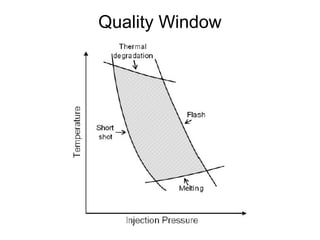

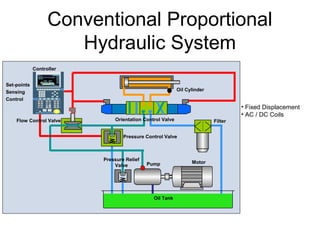

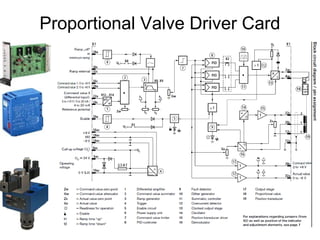

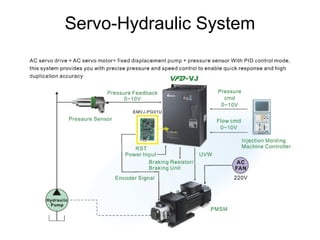

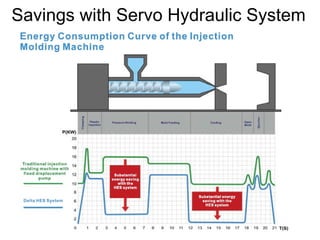

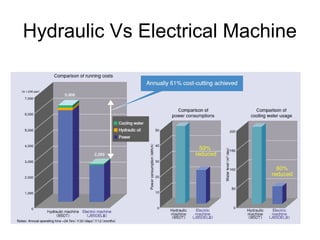

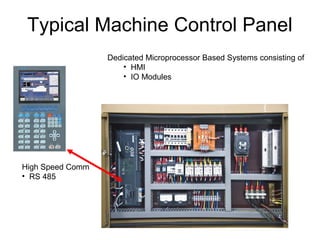

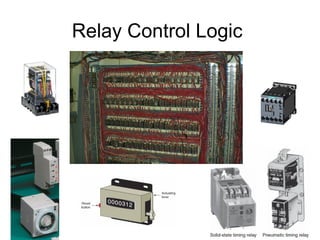

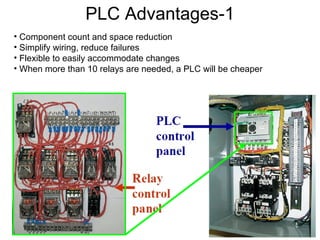

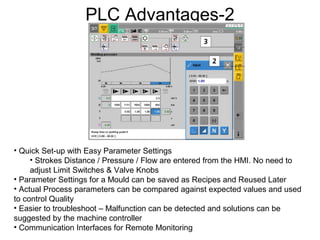

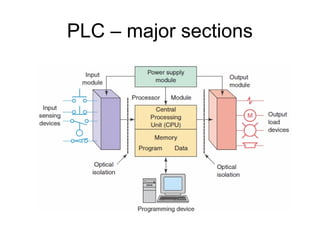

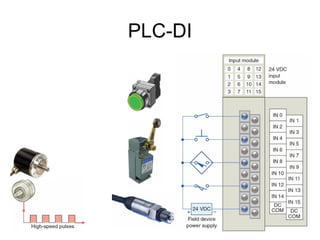

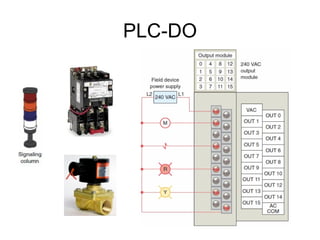

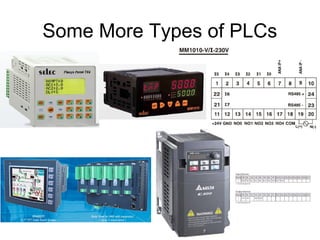

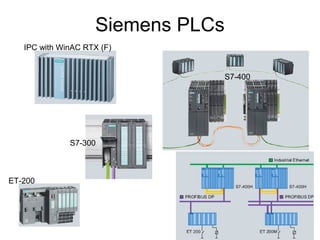

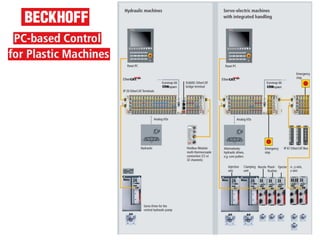

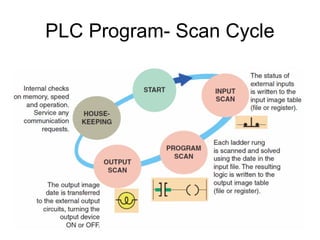

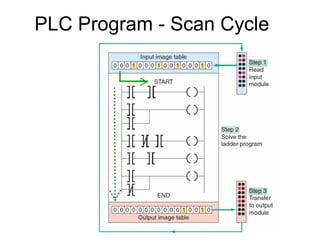

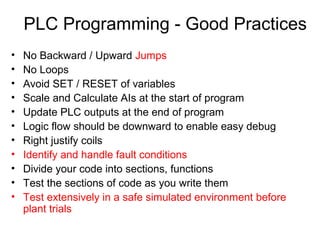

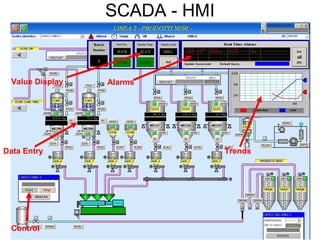

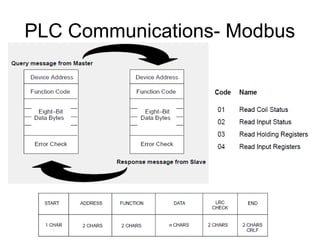

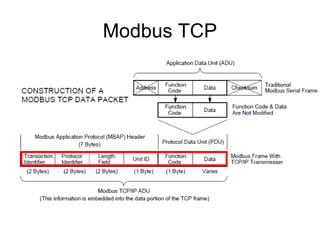

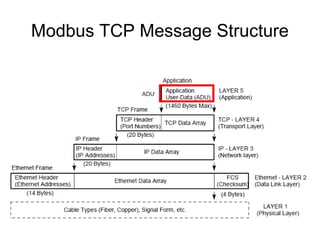

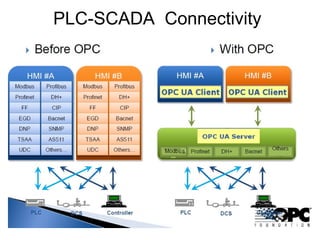

The document discusses machine automation and industrial automation as applied to injection moulding machines. It covers the mechanical, hydraulic, electrical, and electronic systems used in machine automation, including clamping systems, injection units, and hydraulic and servo-hydraulic systems. It also discusses industrial automation hierarchy and trends, including PLCs, HMIs, communications protocols, and the different levels of industrial automation from enterprise systems down to field devices and sensors.

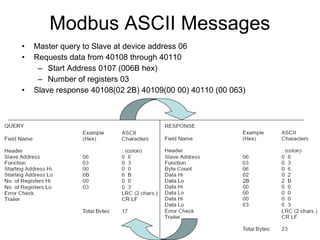

![OPC UA Subscription & Call-backs

Client Server PLC1

10.2.68.1

Create Subscription1 (PLC1@1s)

Subscription1 Handle

Add Subscription1.Item1 (40108)

Item1 Handle

Read Req (10.2.68.1 03 0107)

OPC UA Modbus TCP

Read Res (03 0000)

PLC1

10.2.68.1

Item1 Update (VTQ) [ INITIAL]

Read Res (03 0000)

Read Req (10.2.68.1 03 0107)

Read Res (03 0001)

Read Req (10.2.68.1 03 0107)

Item1 Update (VTQ) [ VALUE CHANGE]

Remove Item1

Delete Subscription1

1s](https://image.slidesharecdn.com/mechatronics-190316084004/85/Mechatronics-and-the-Injection-Moulding-Machine-48-320.jpg)