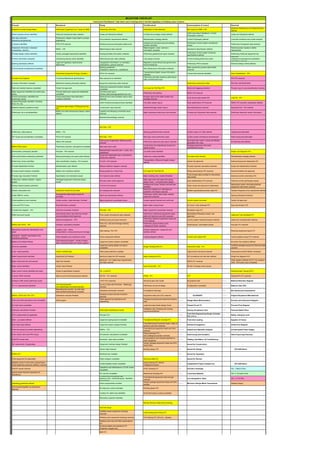

This document outlines the key milestones and deliverables in a process plant design project from conceptual design through detailed design and construction. It includes milestones for various disciplines like process, mechanical, piping, civil/structural, instrumentation and control, and electrical. The milestones range from developing preliminary design criteria and equipment lists to issuing design packages, finalizing vendor data, and completing construction drawings.