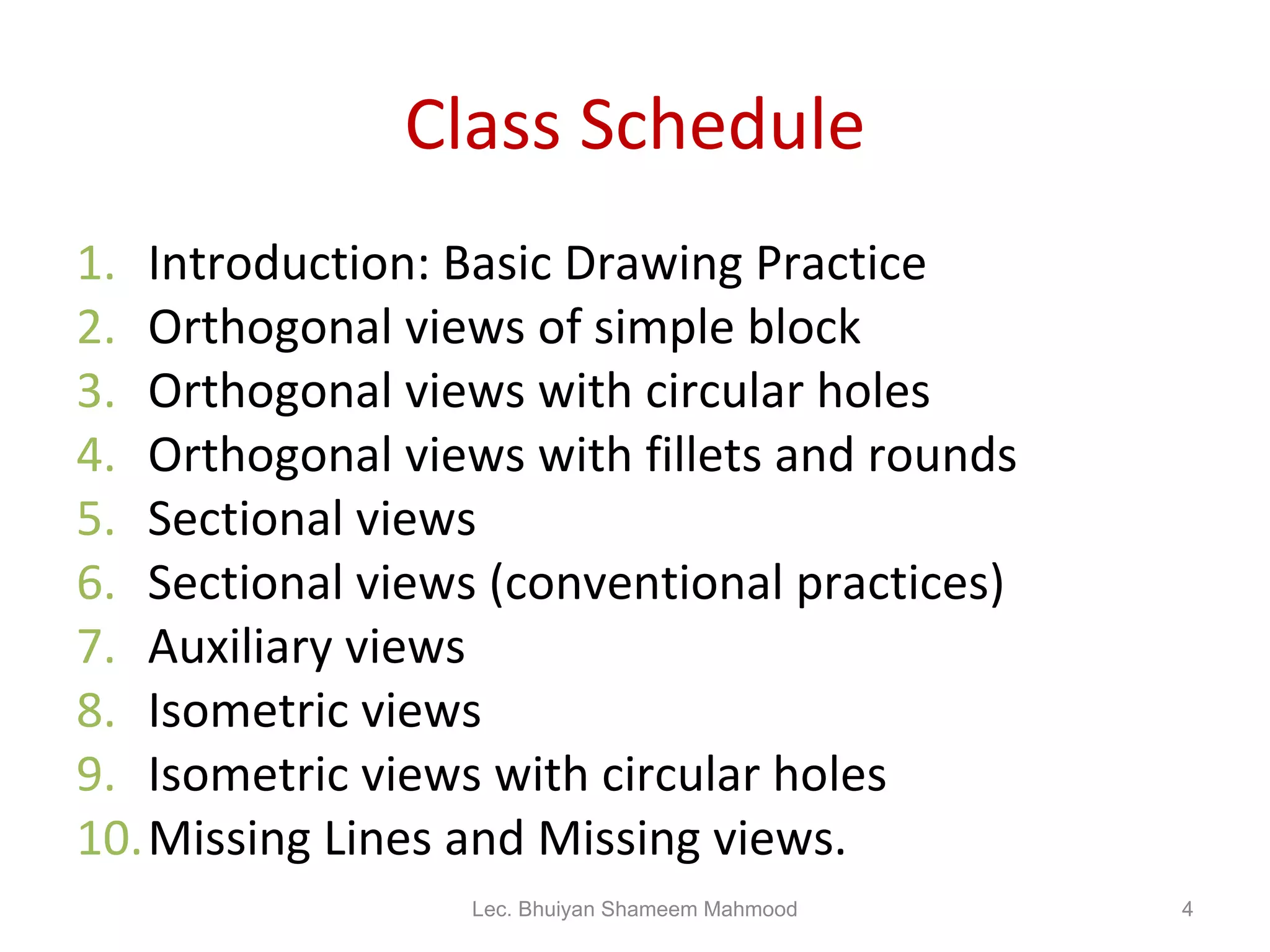

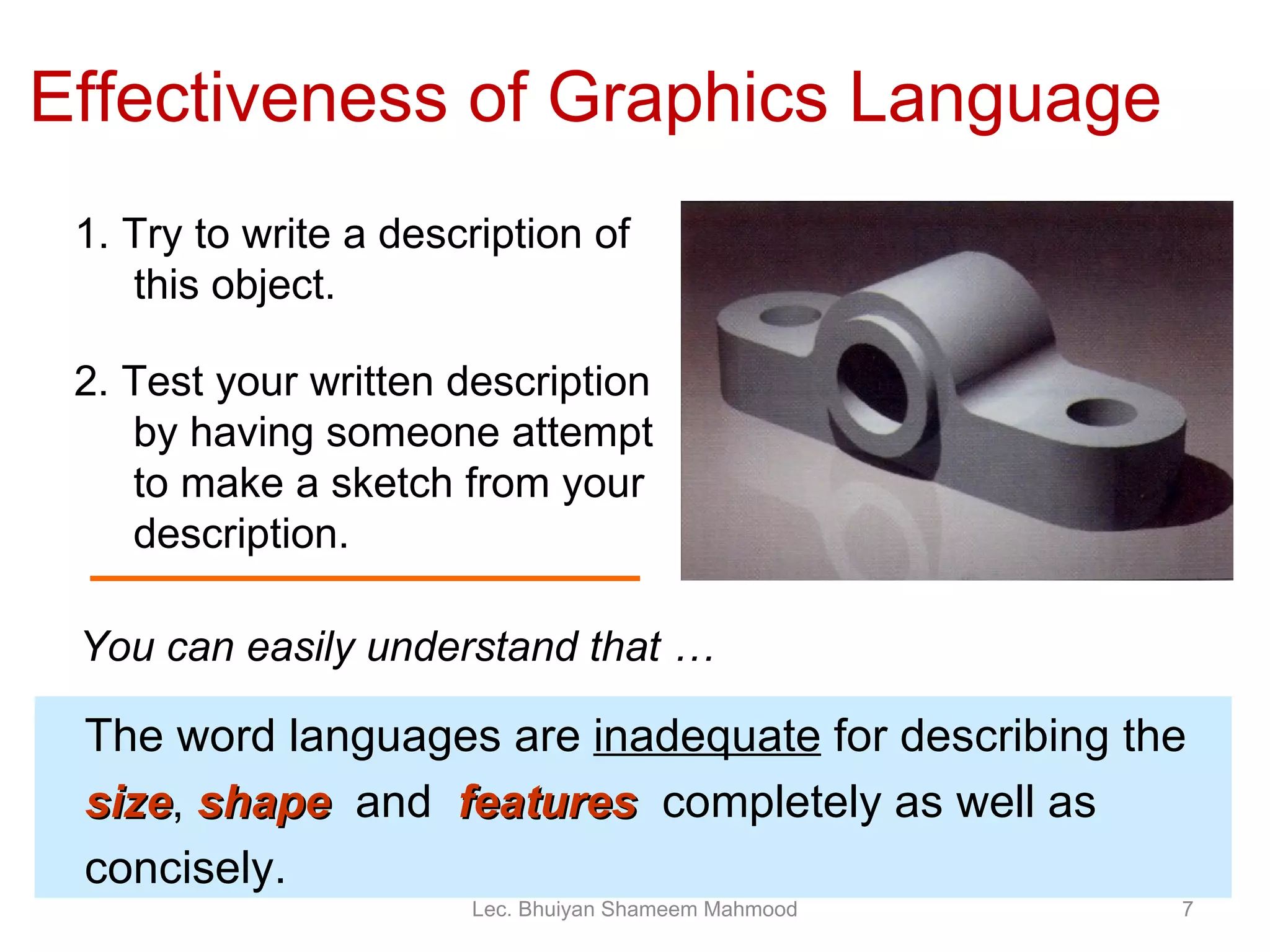

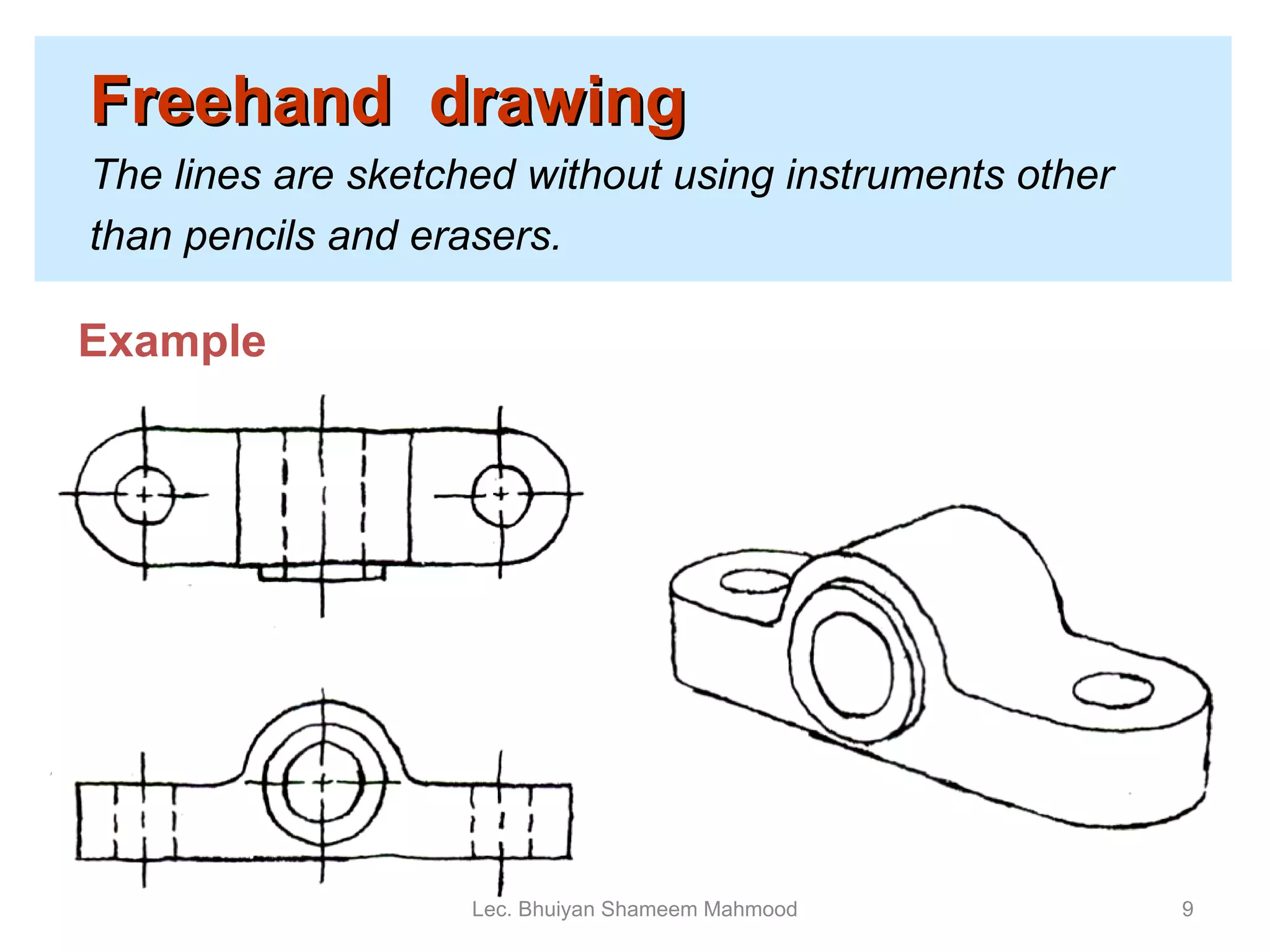

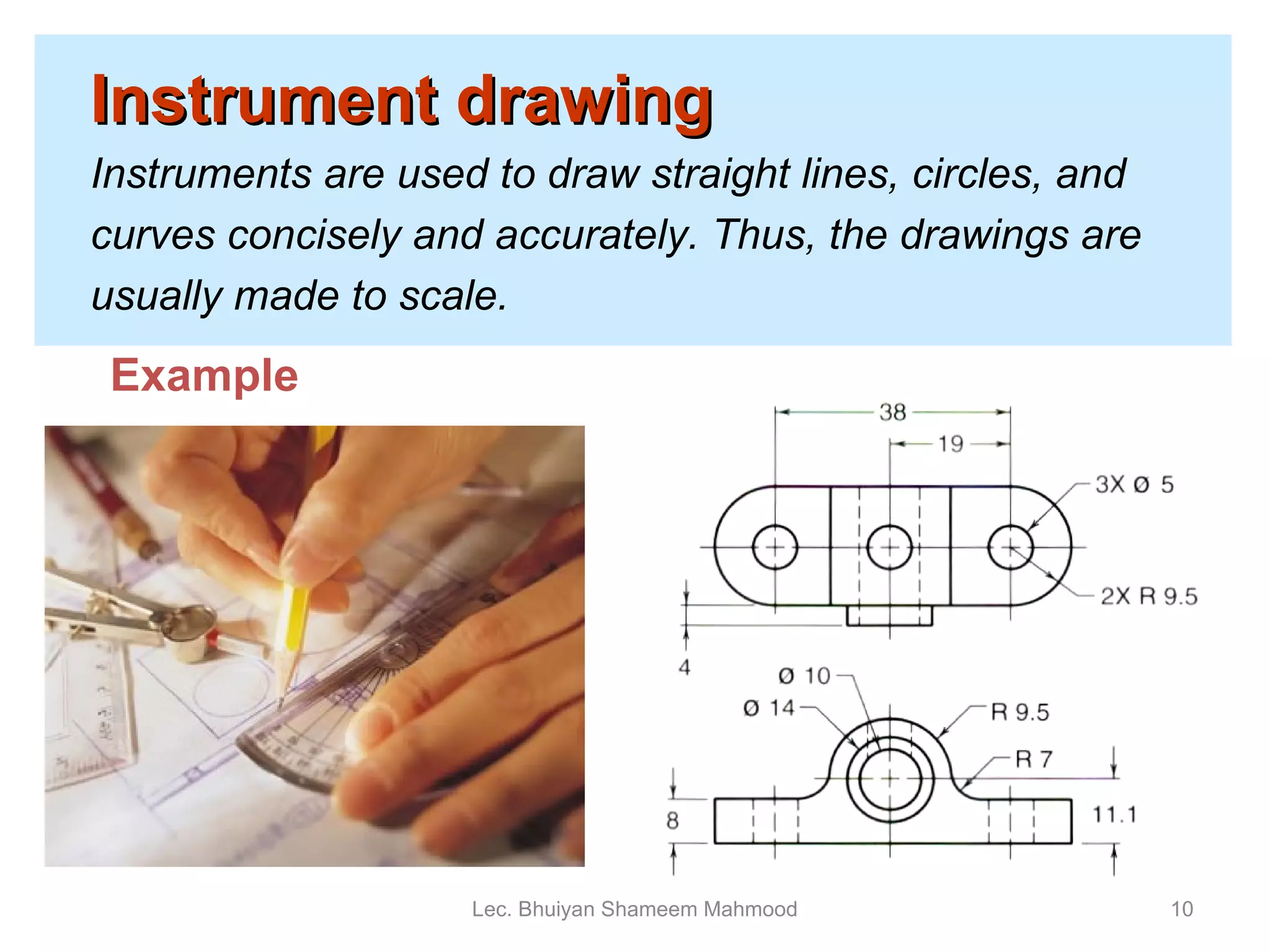

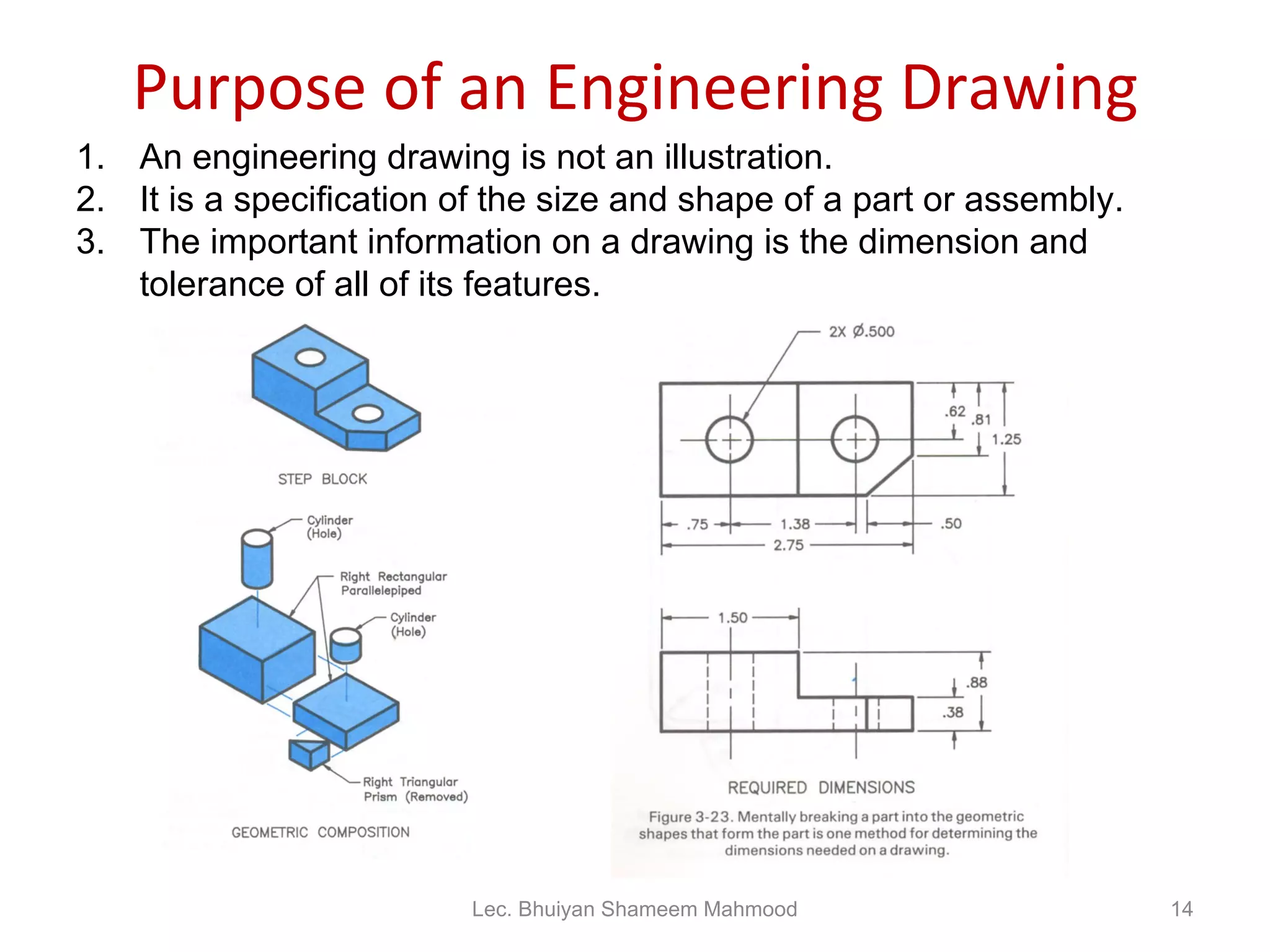

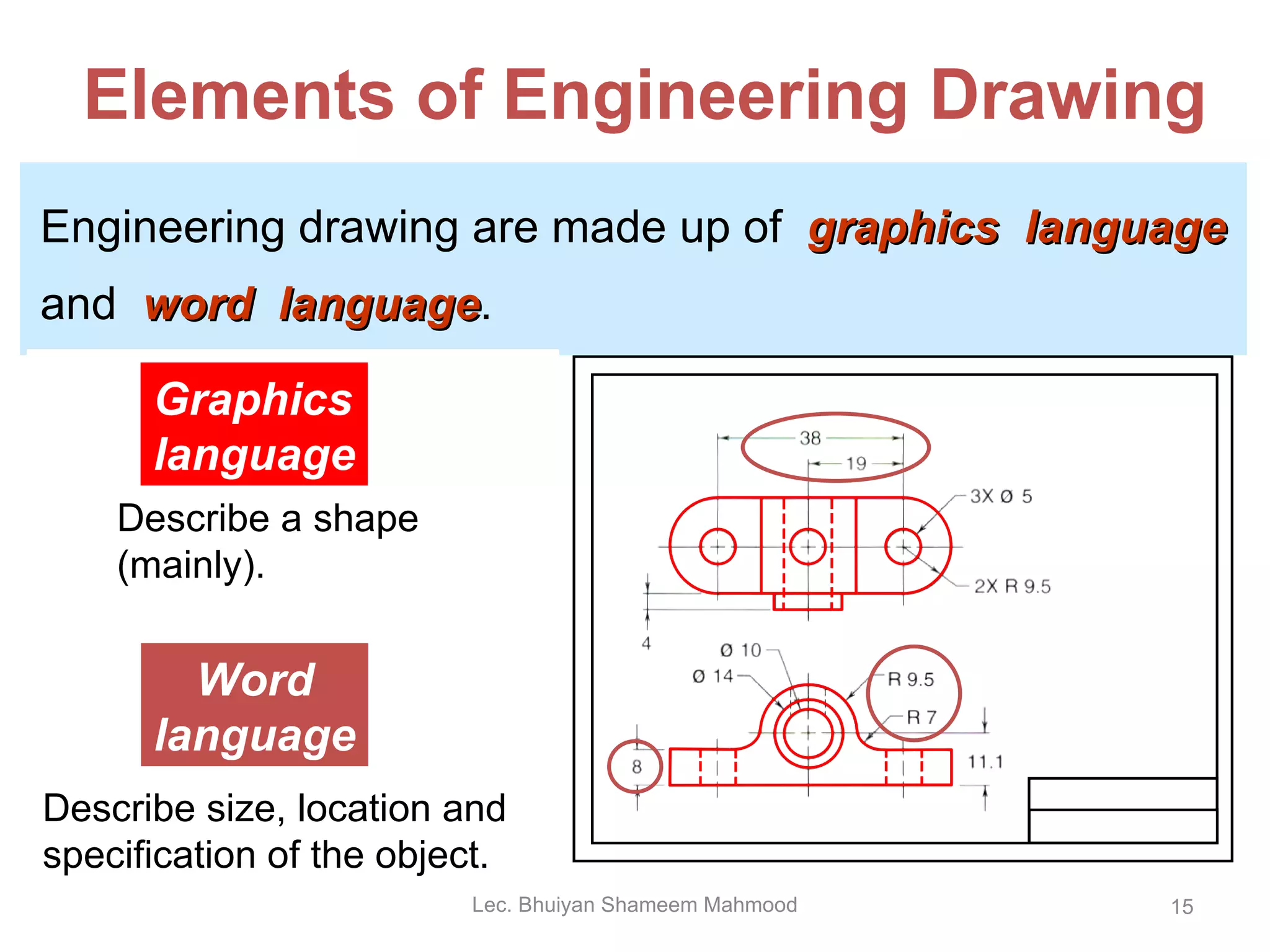

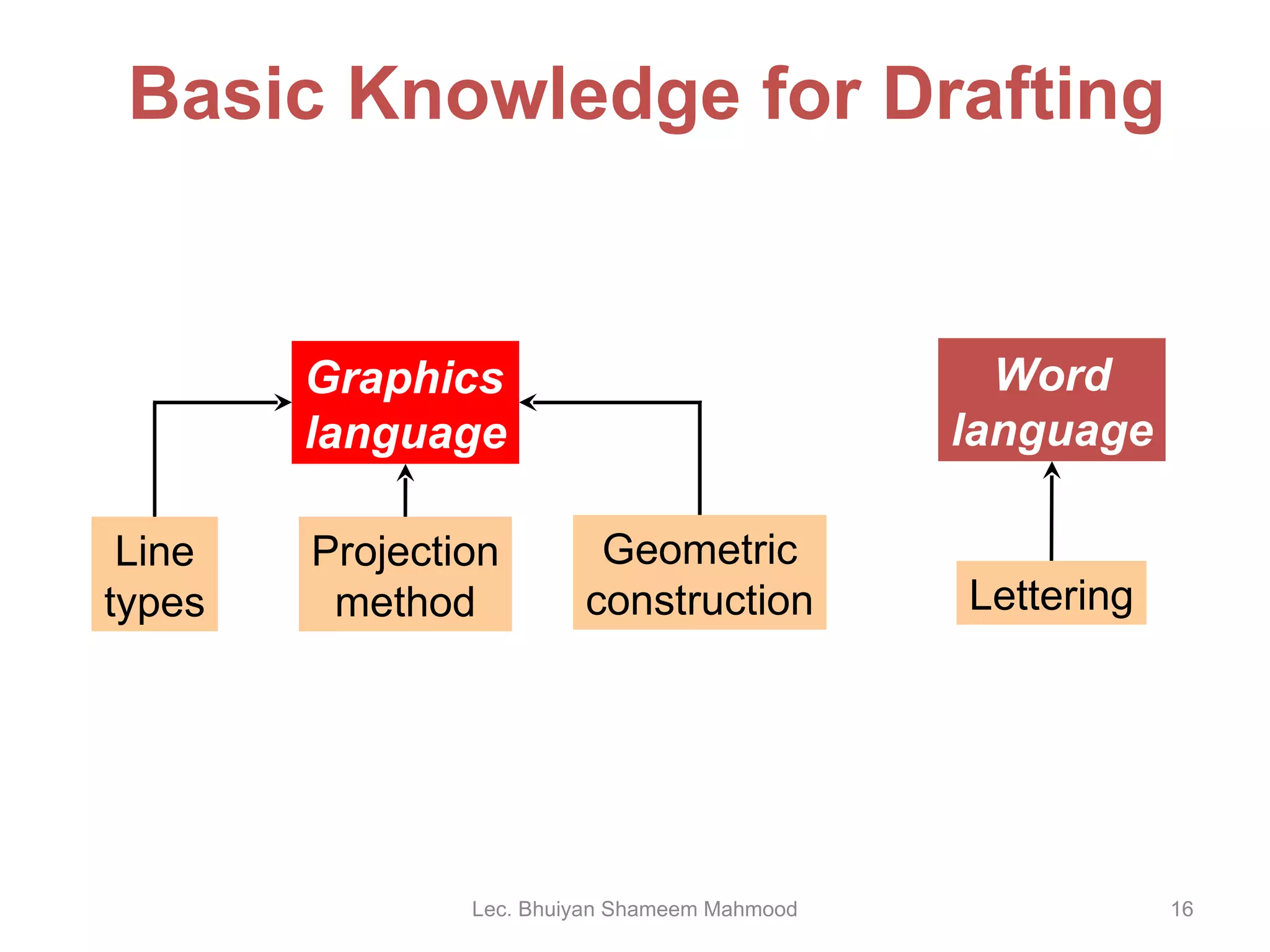

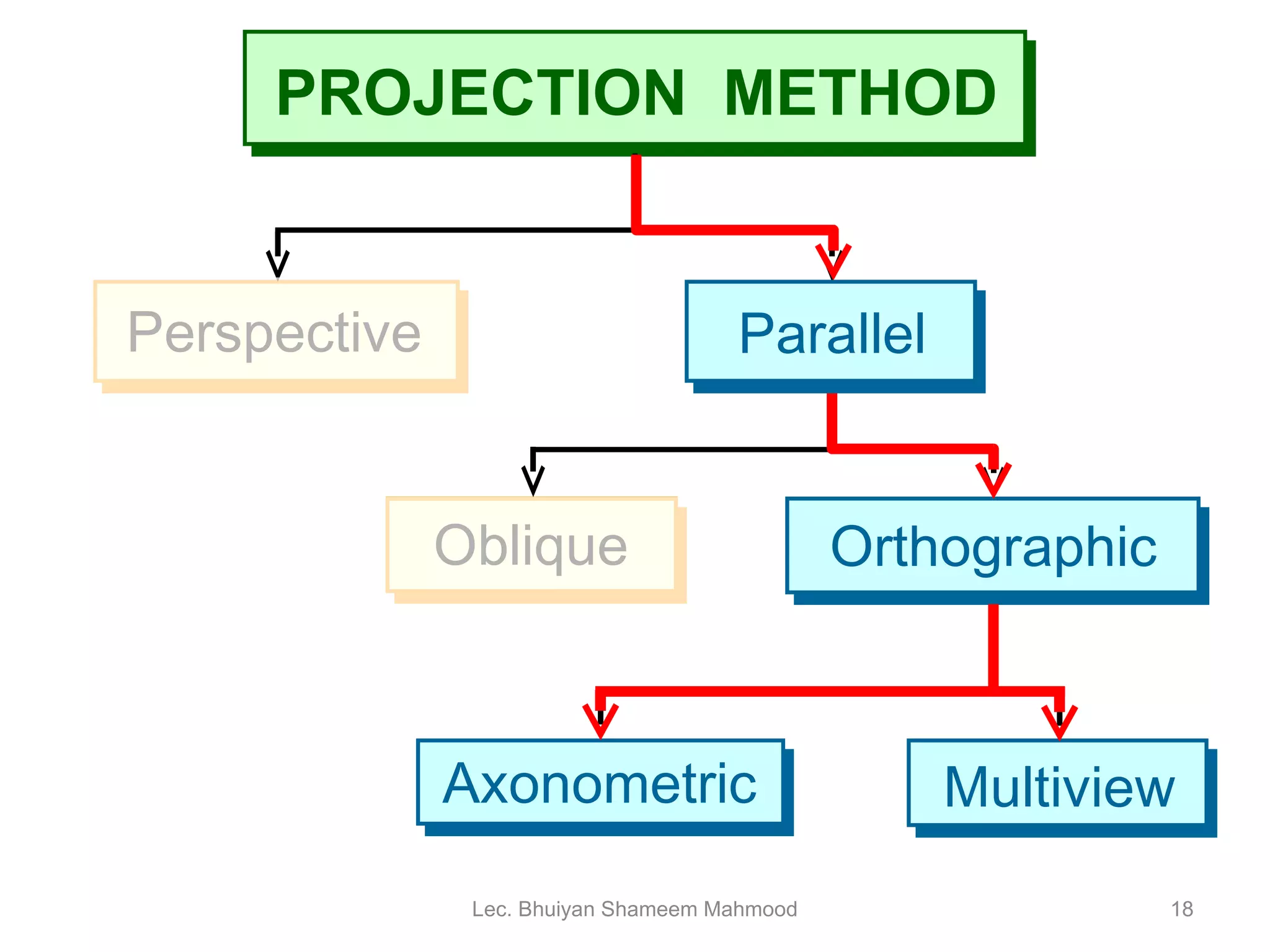

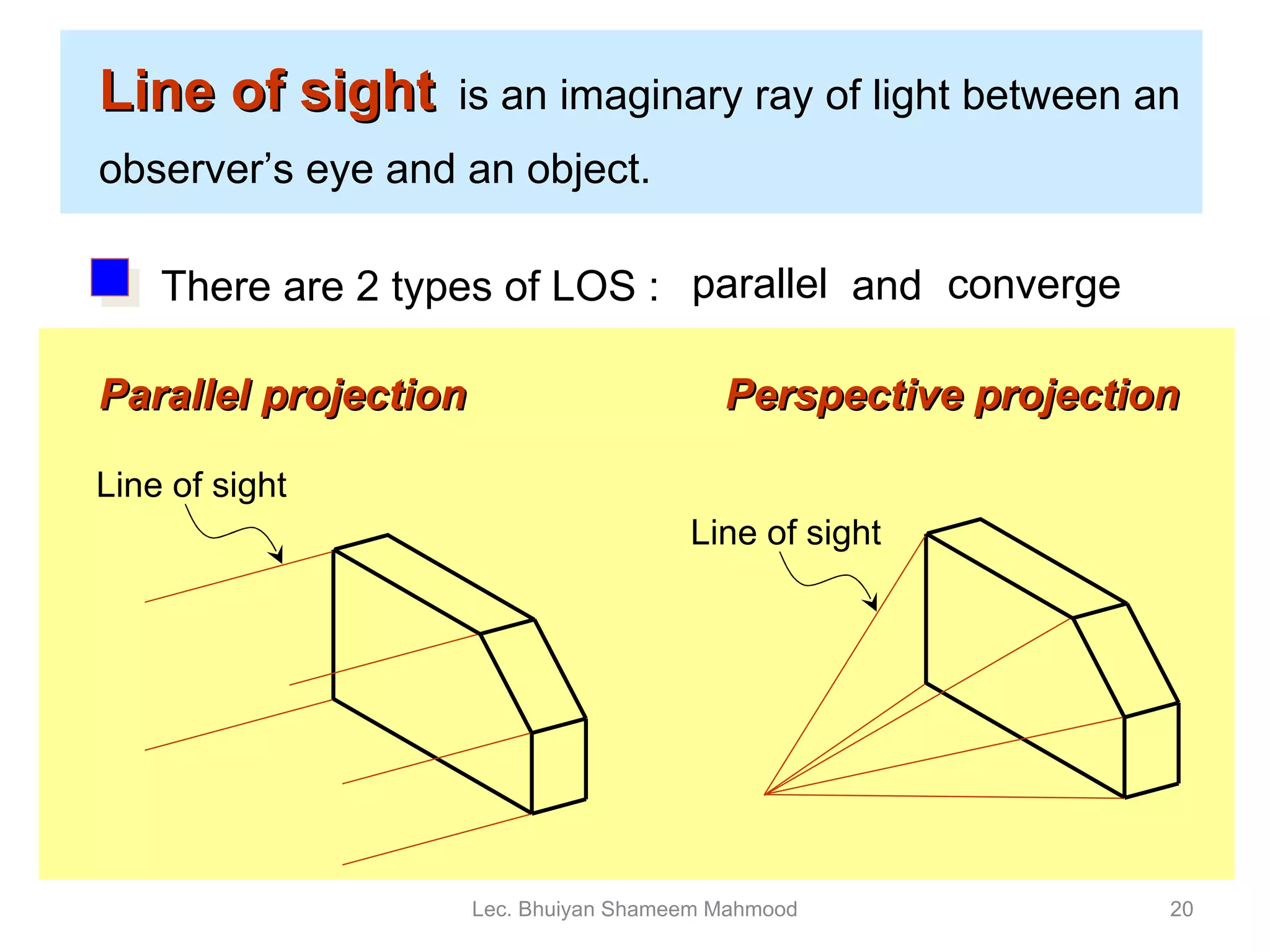

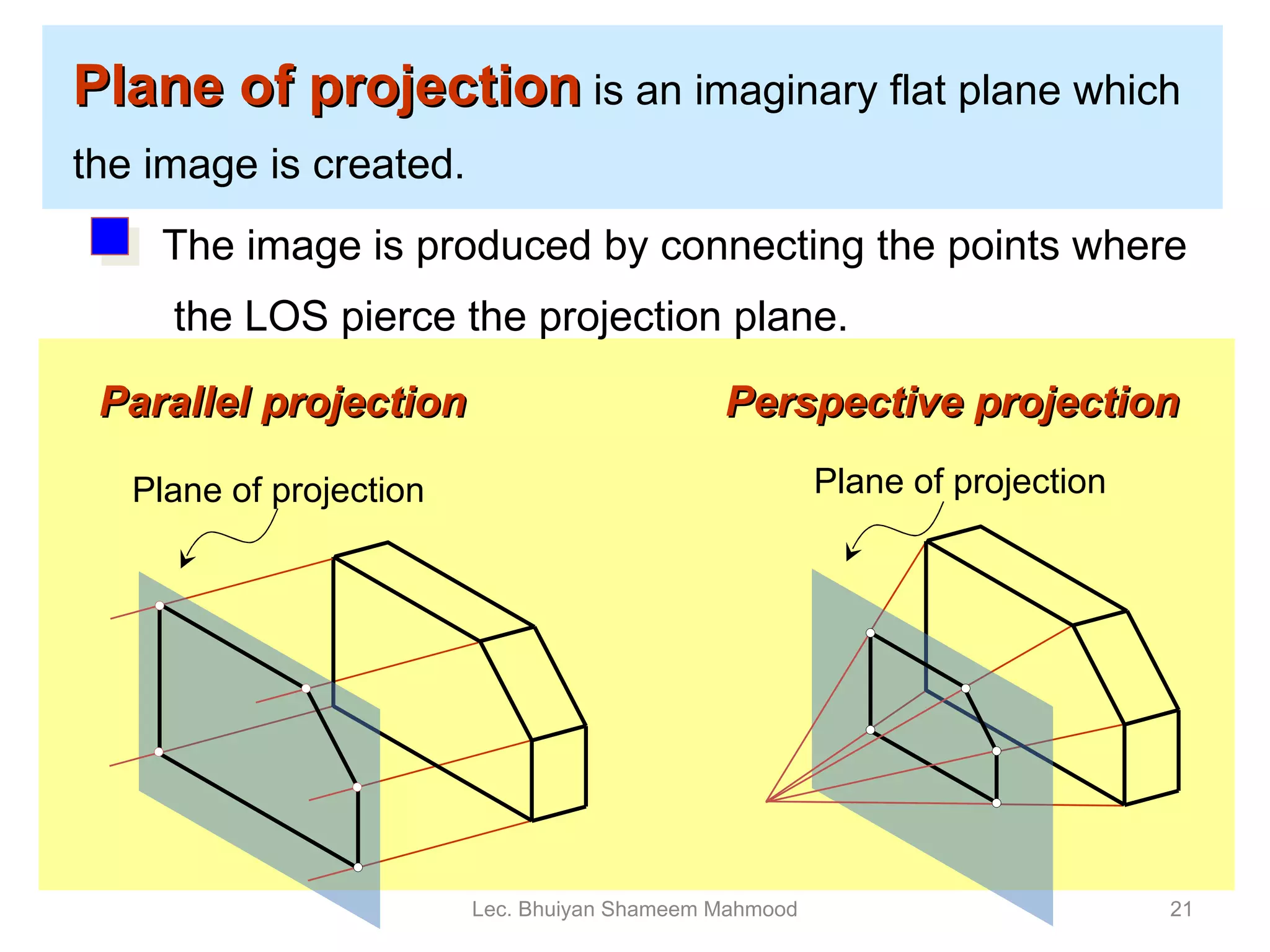

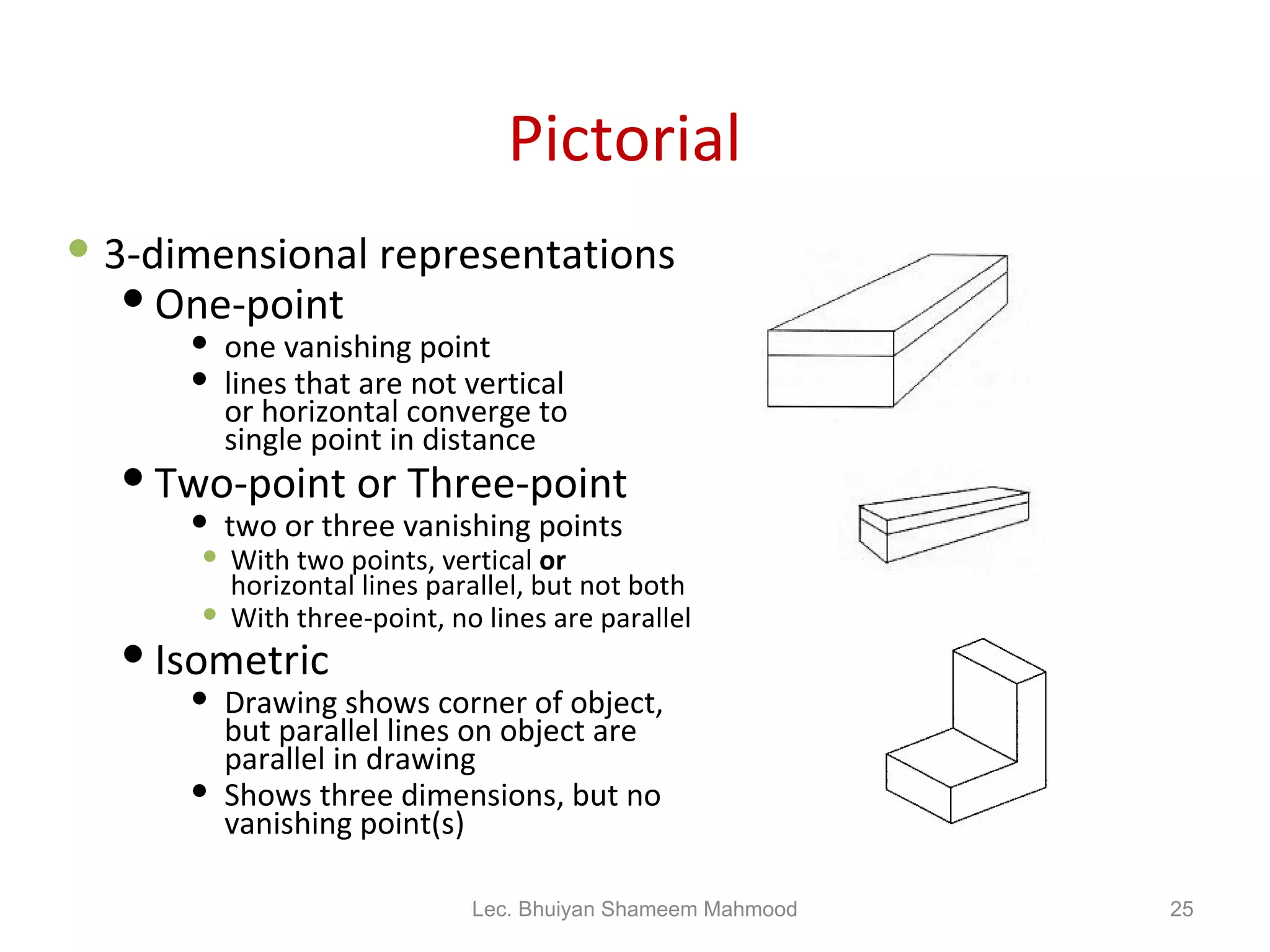

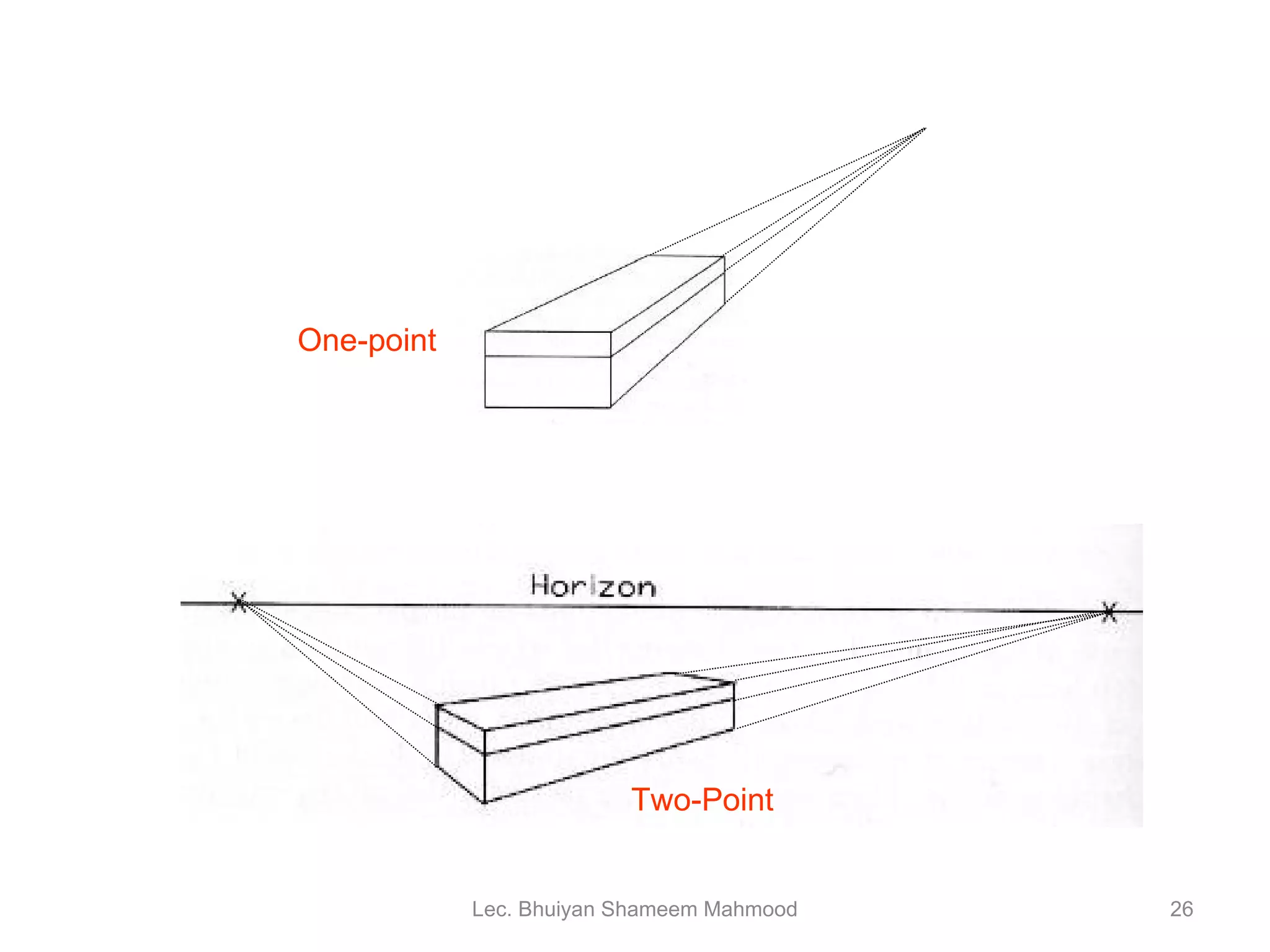

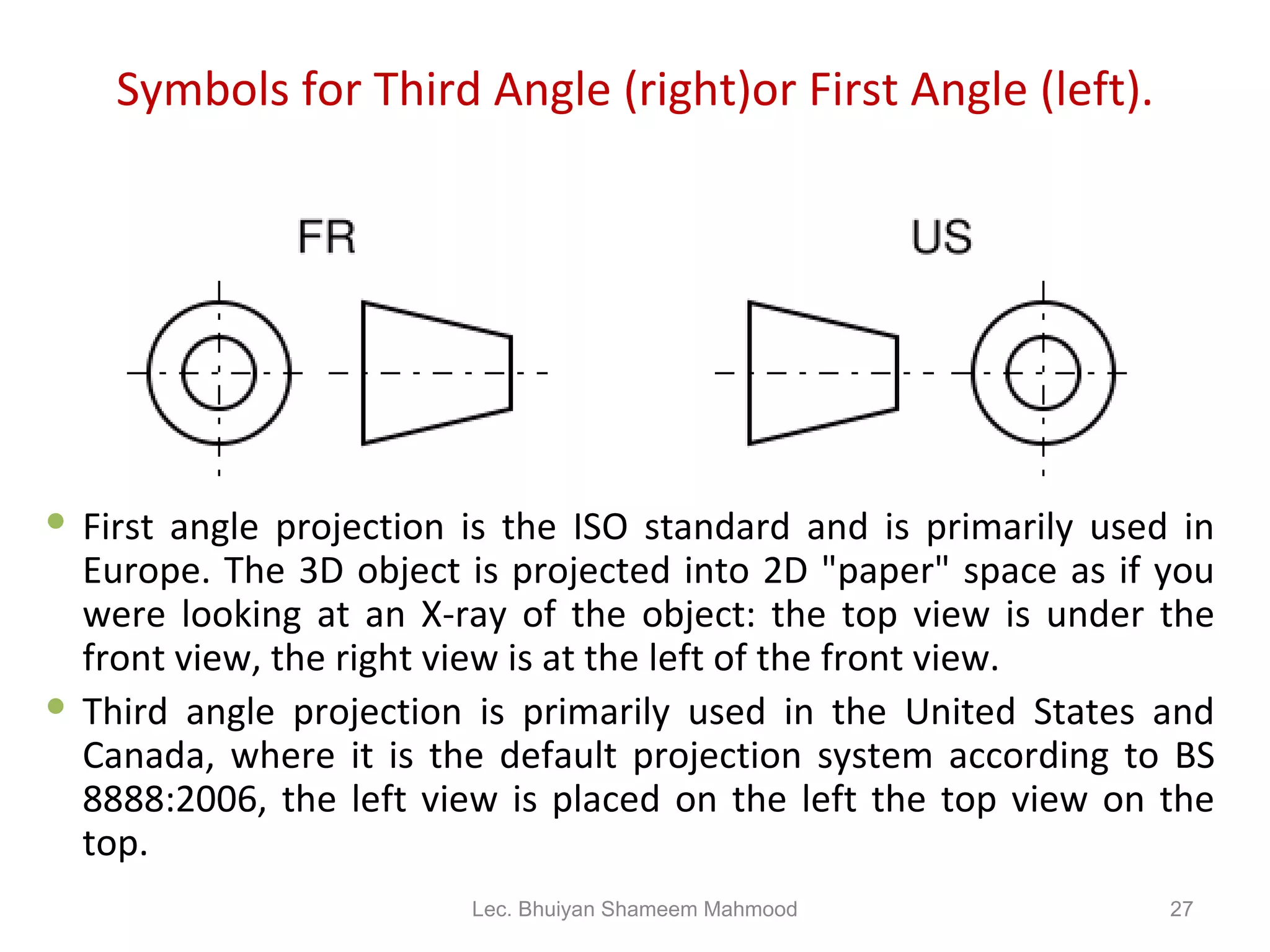

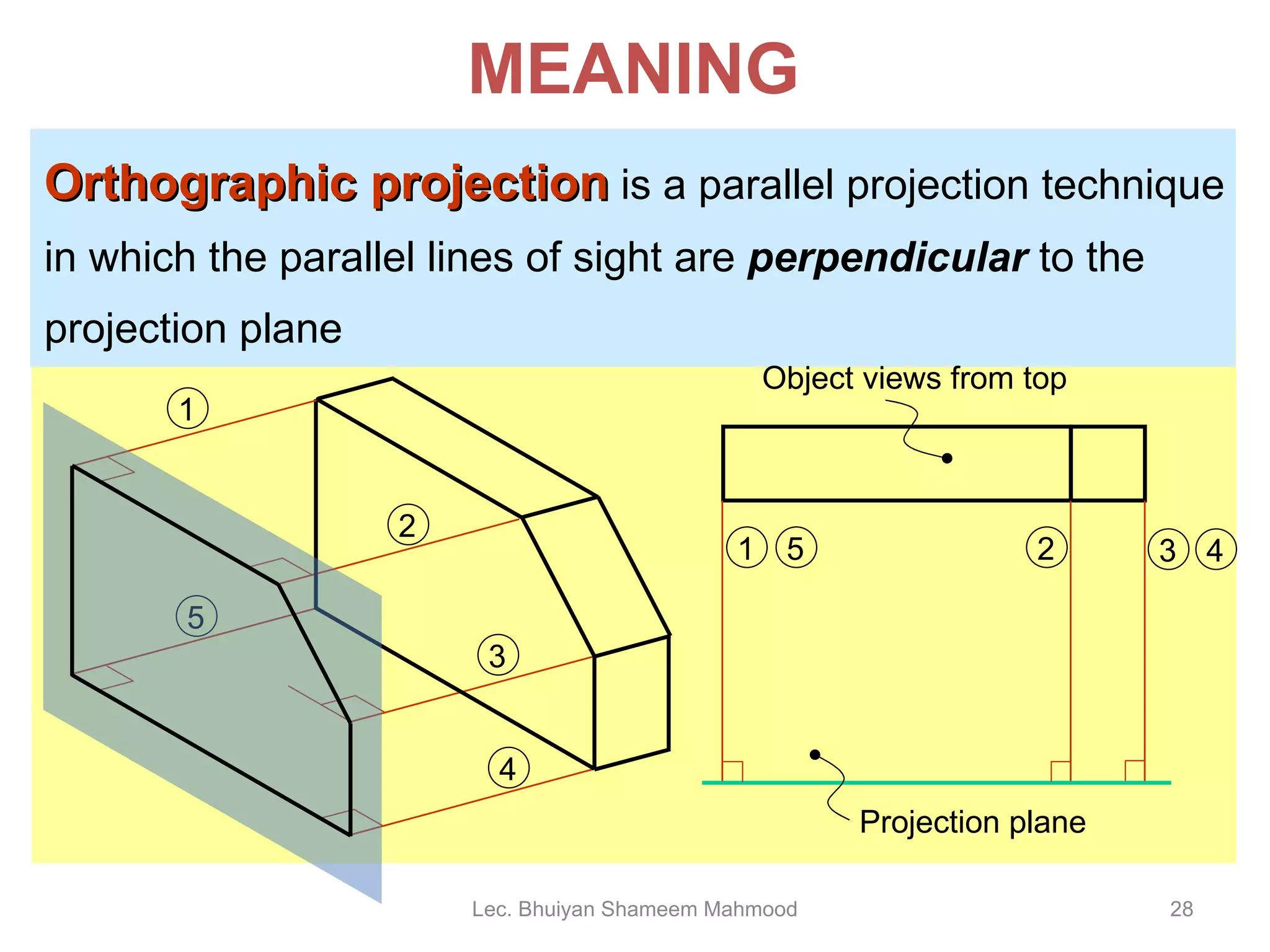

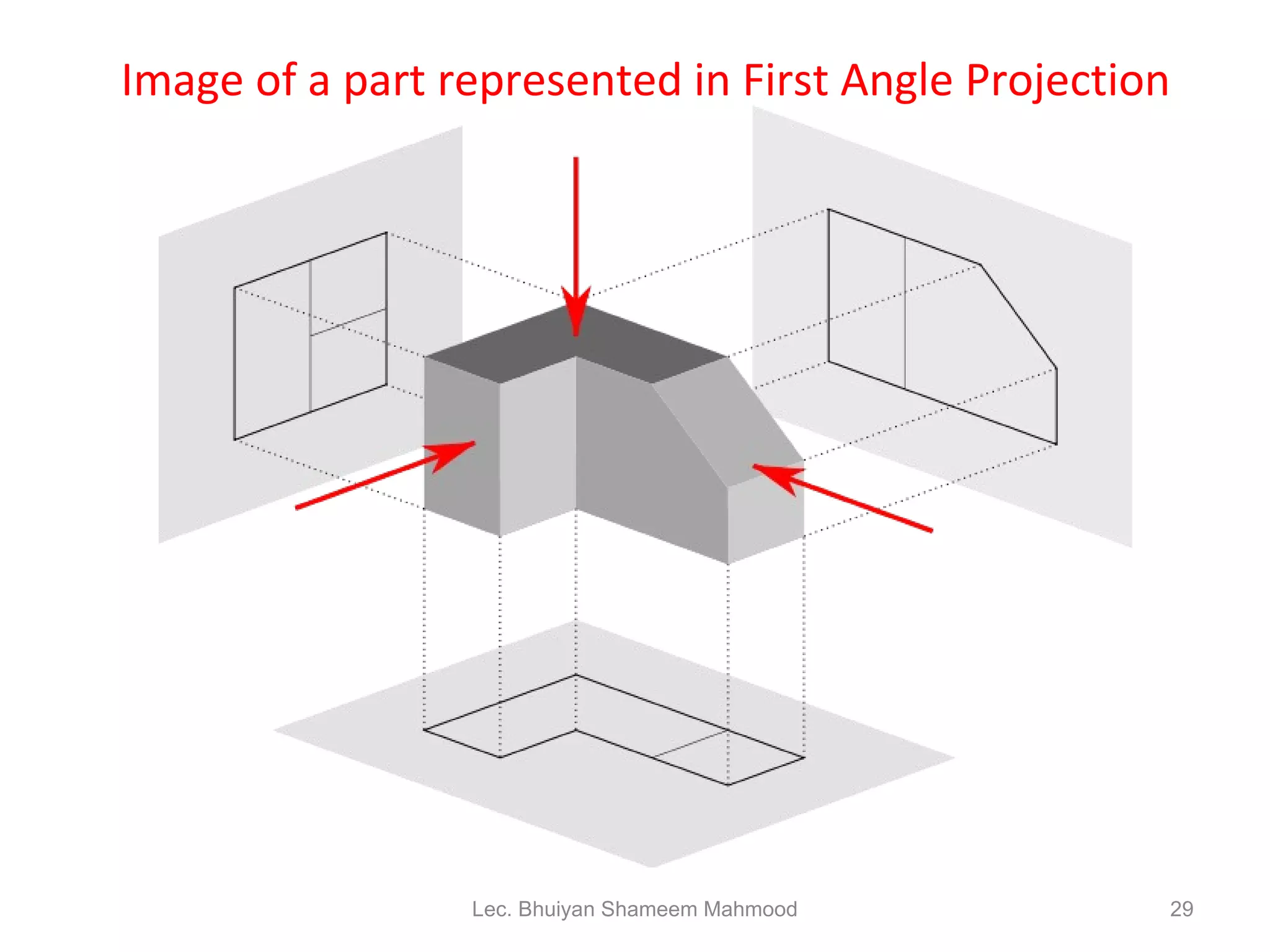

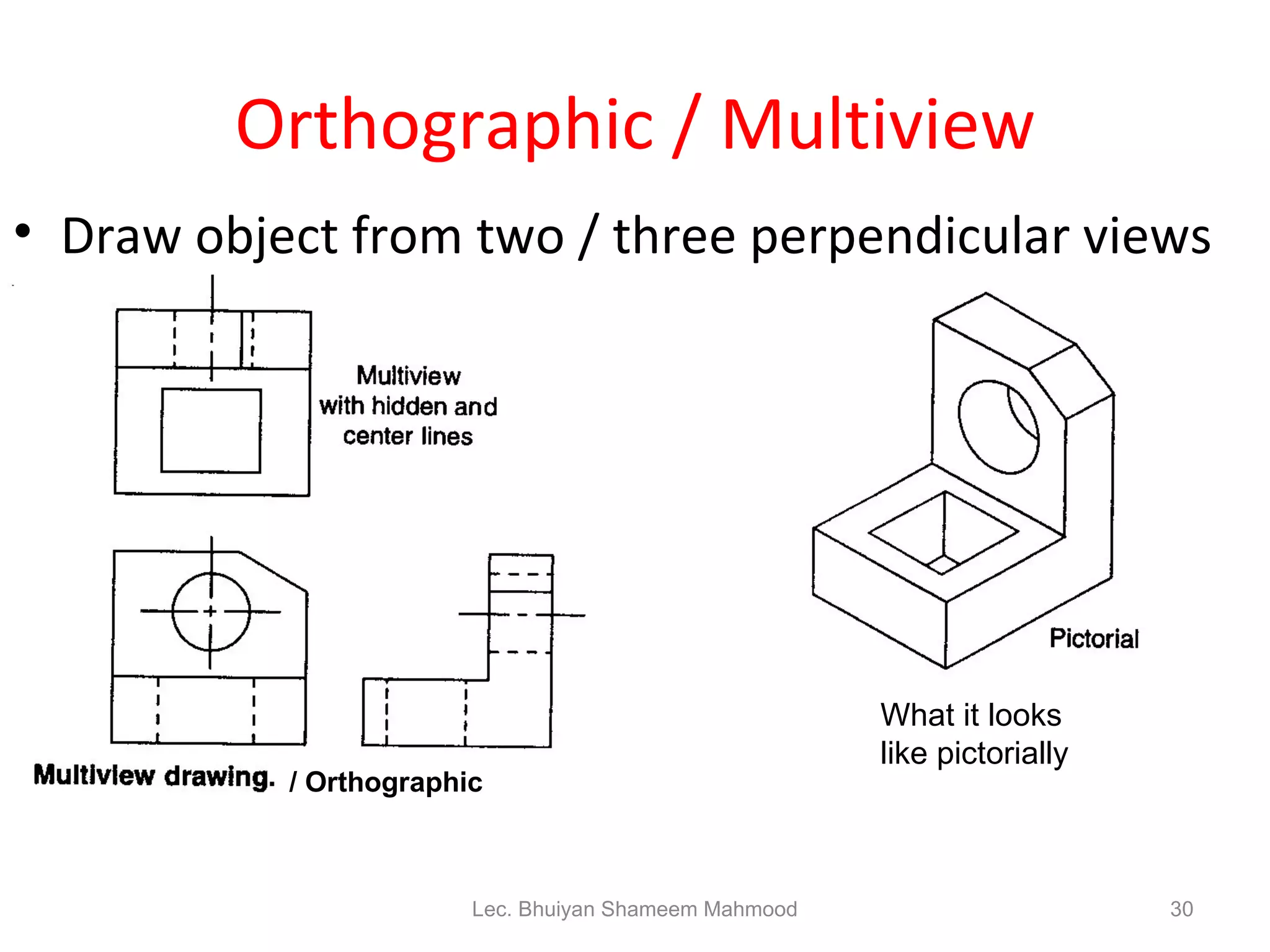

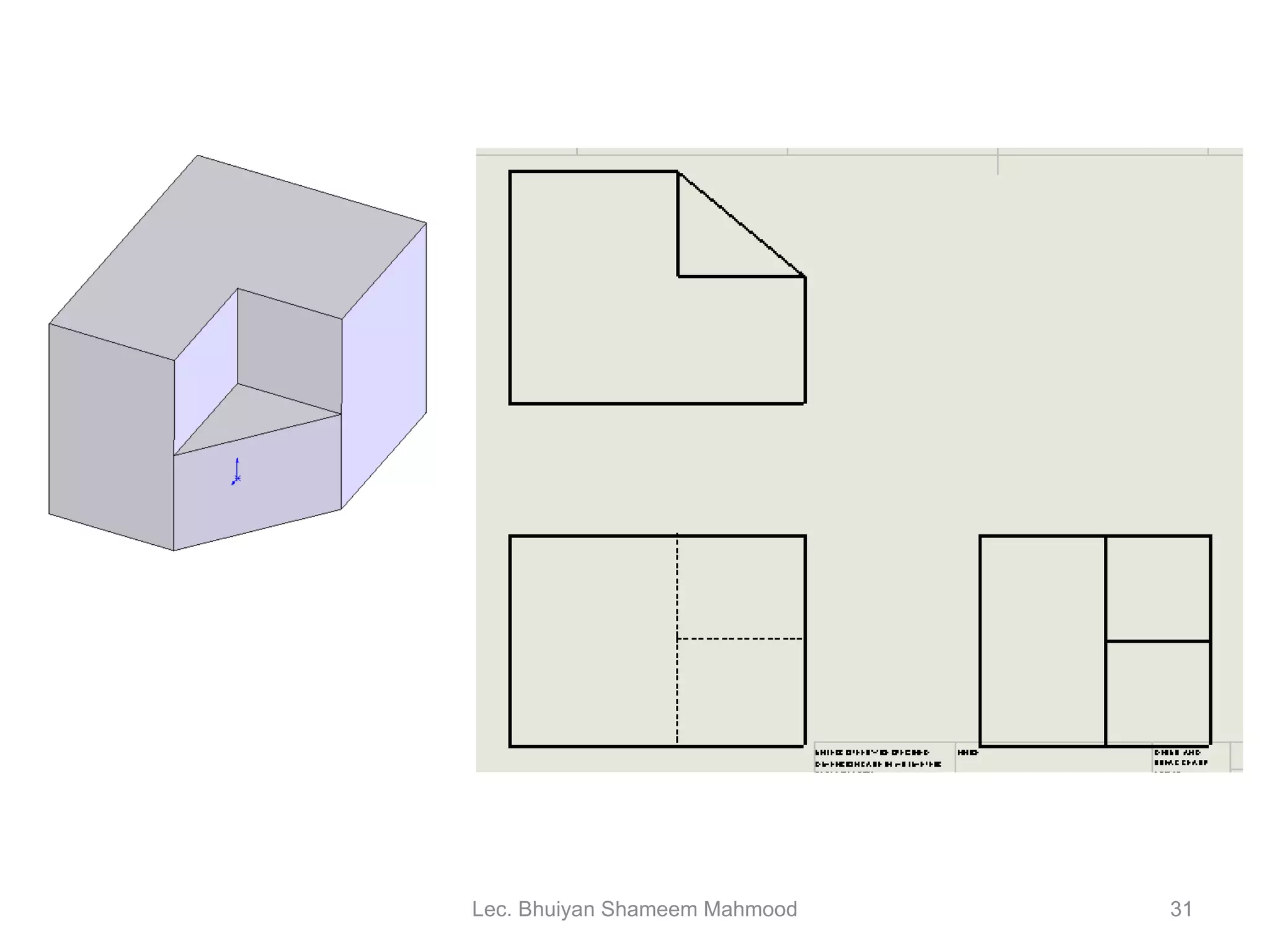

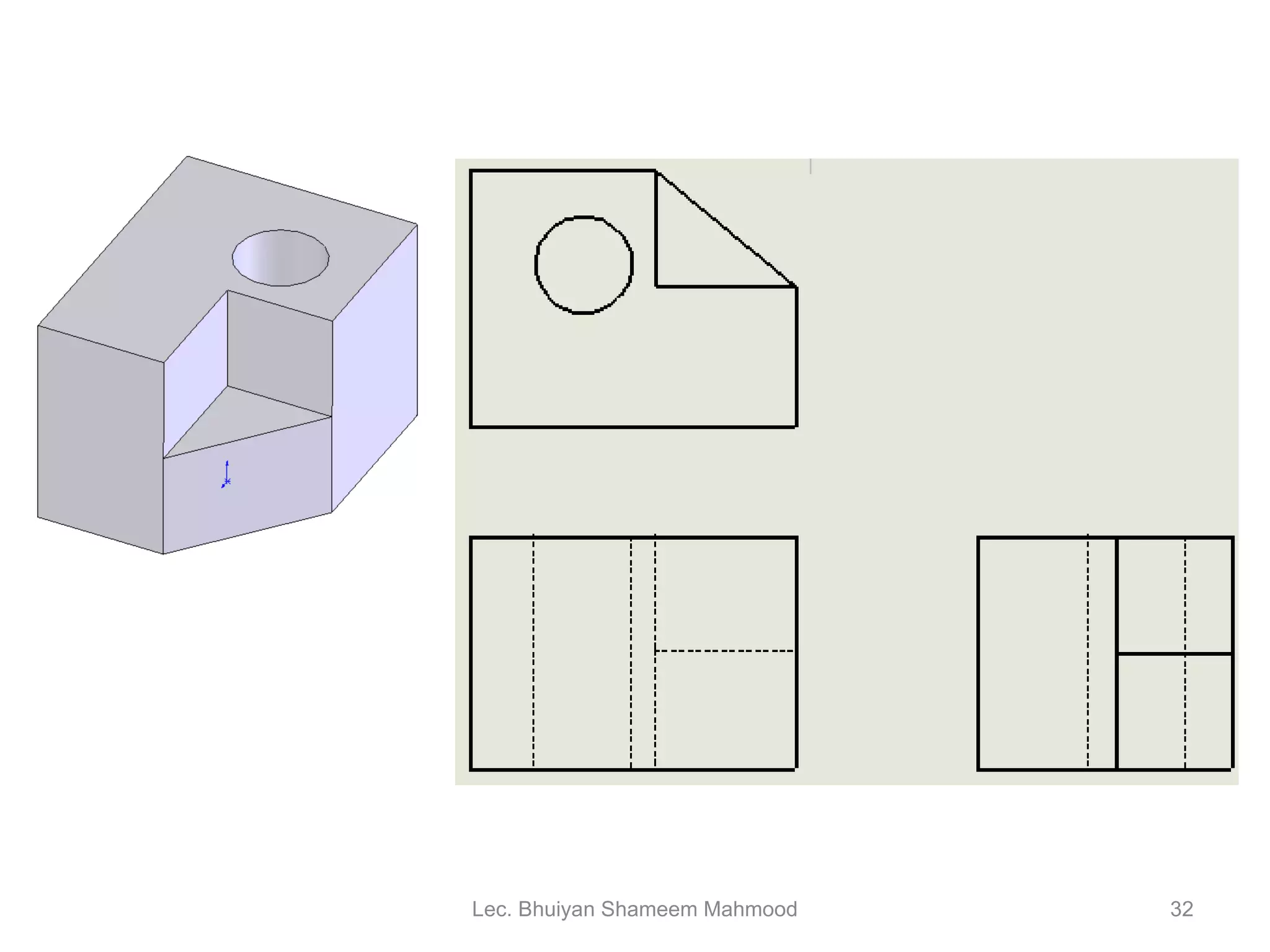

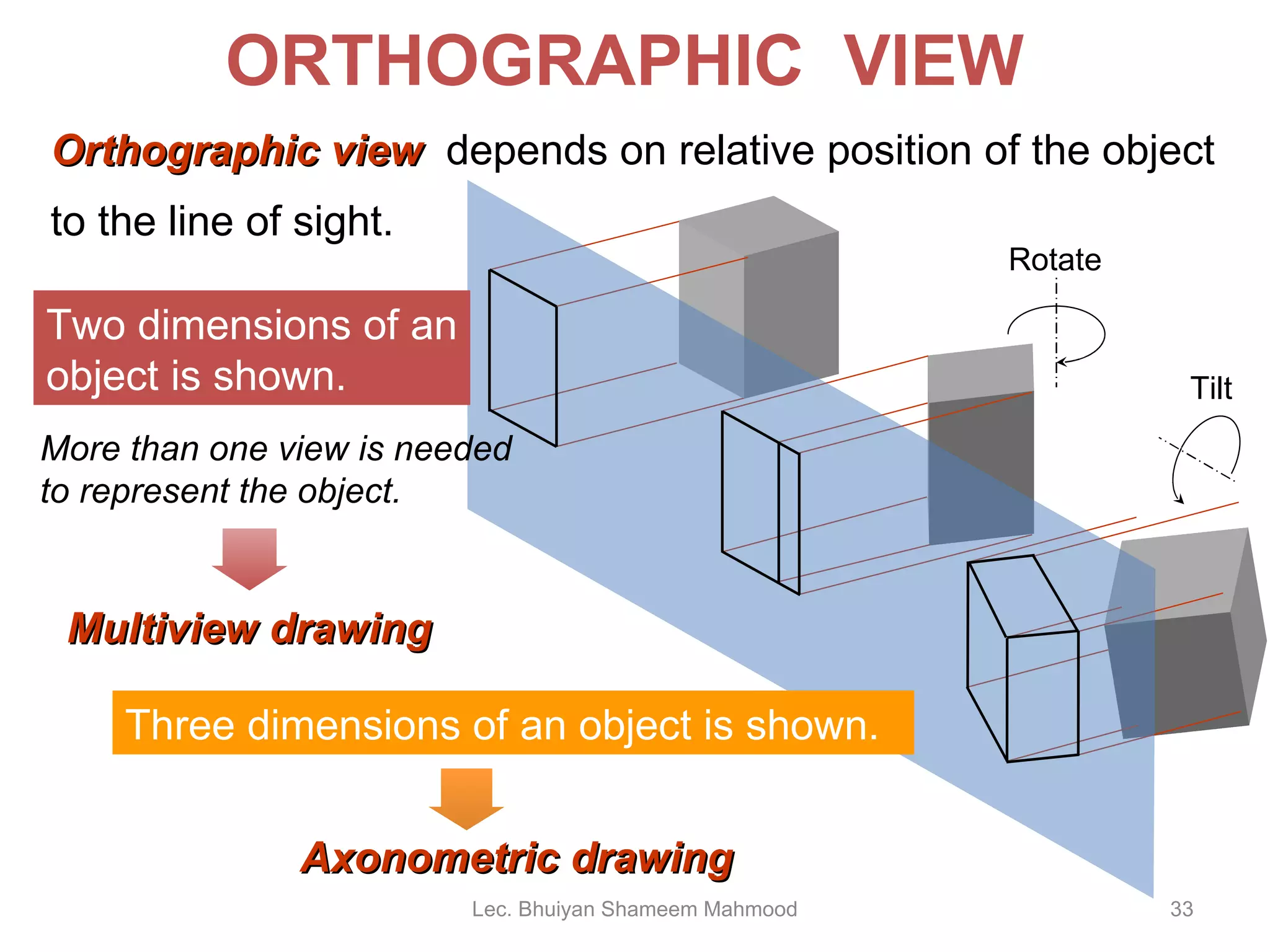

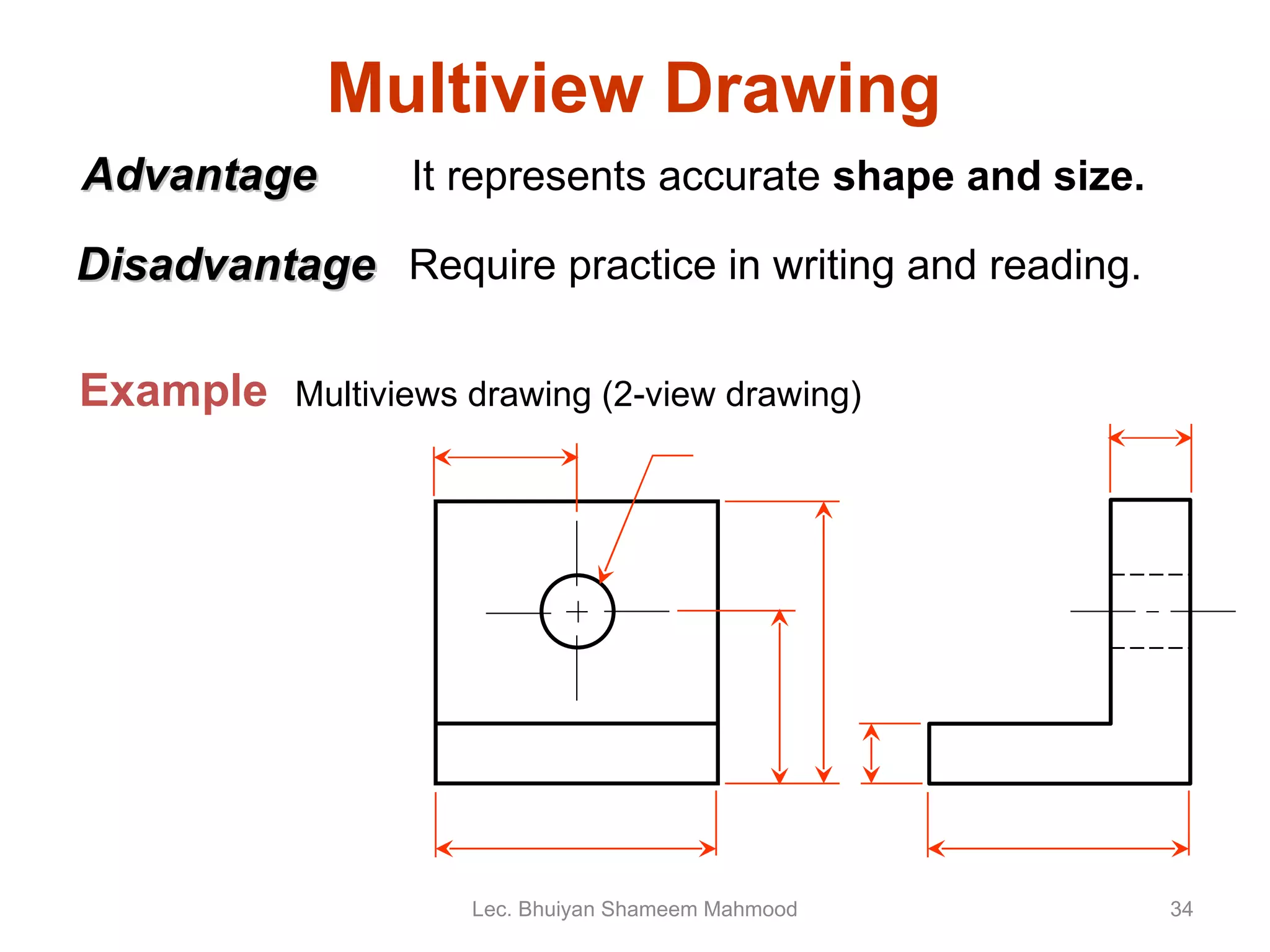

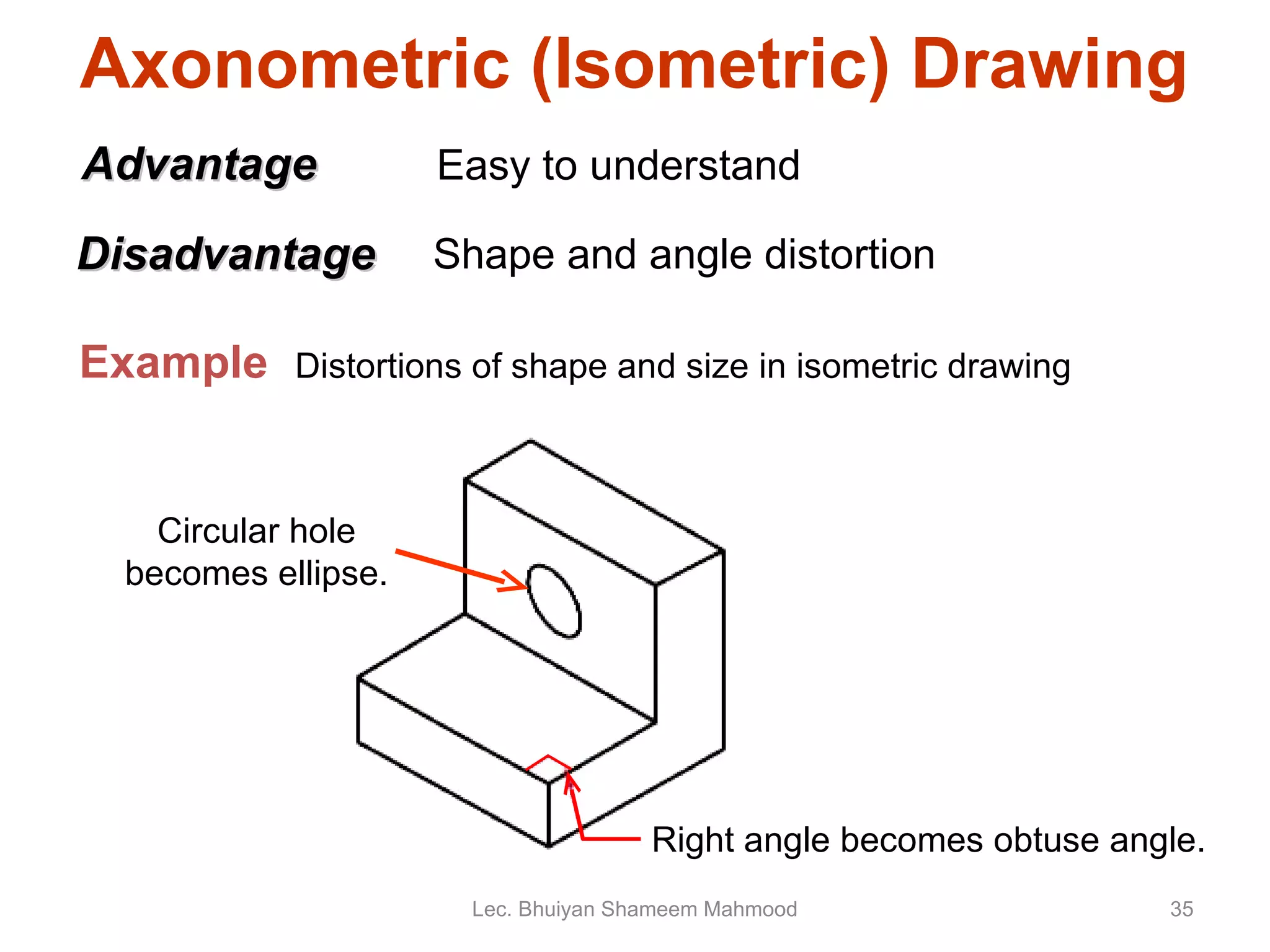

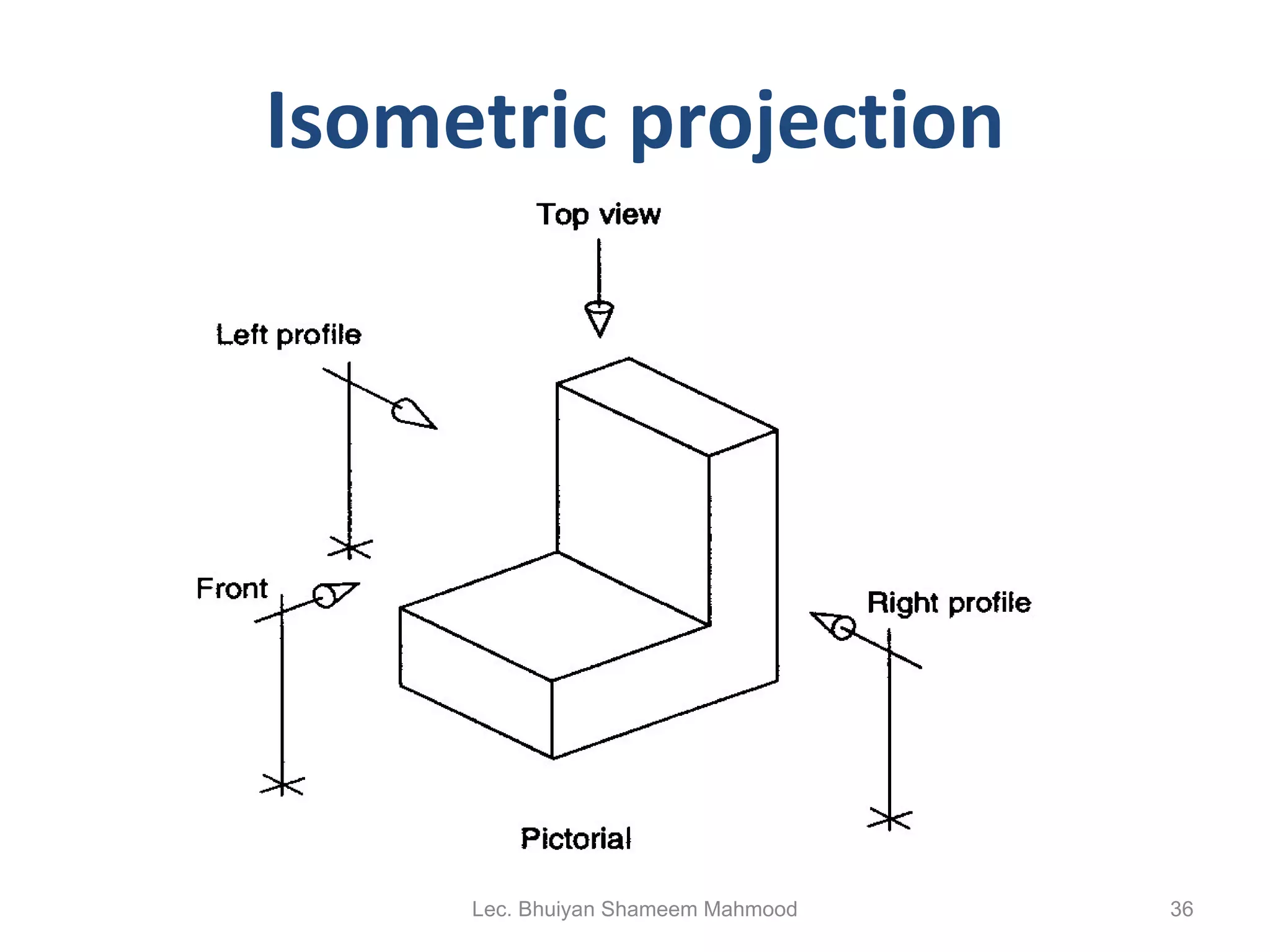

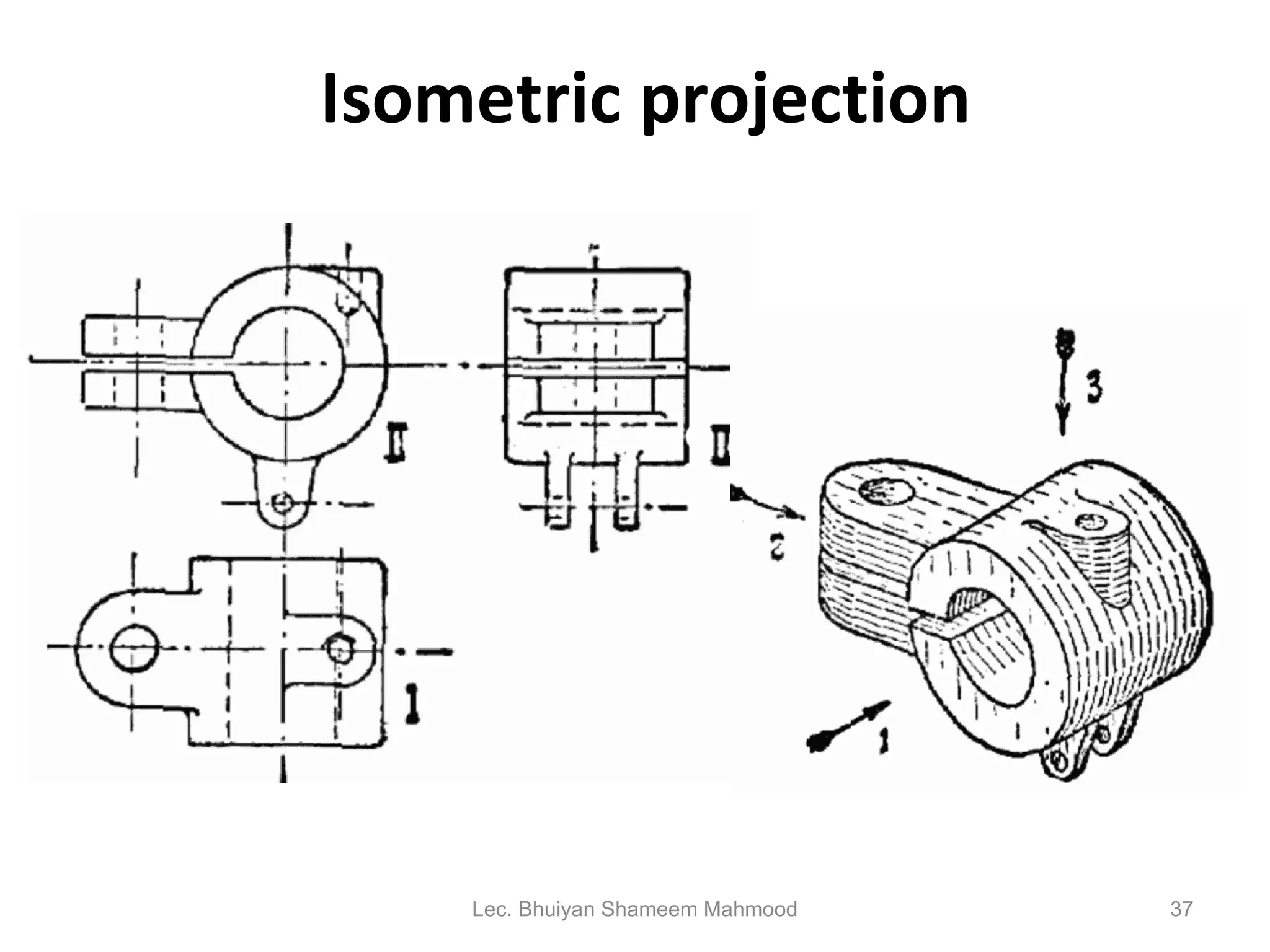

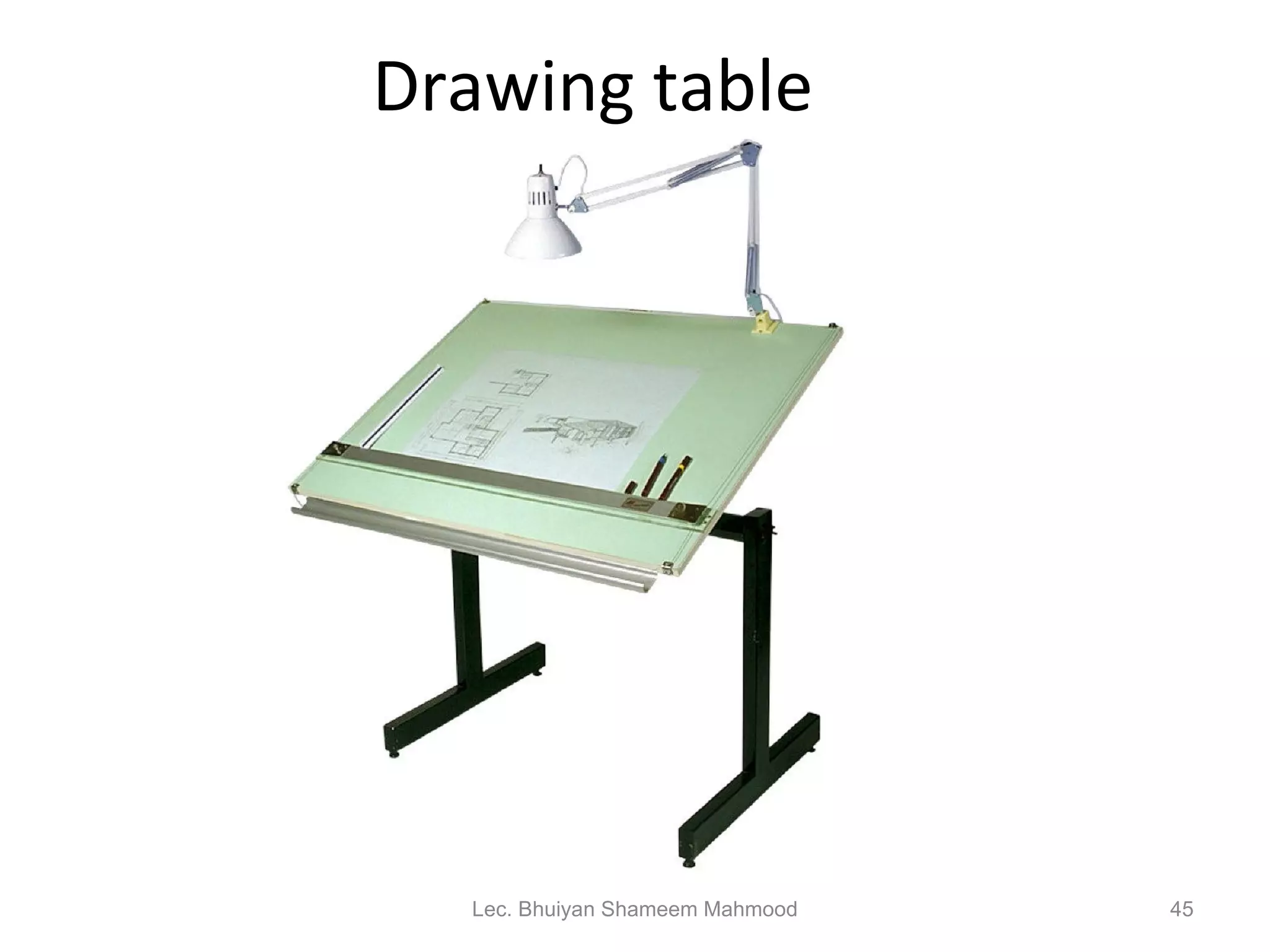

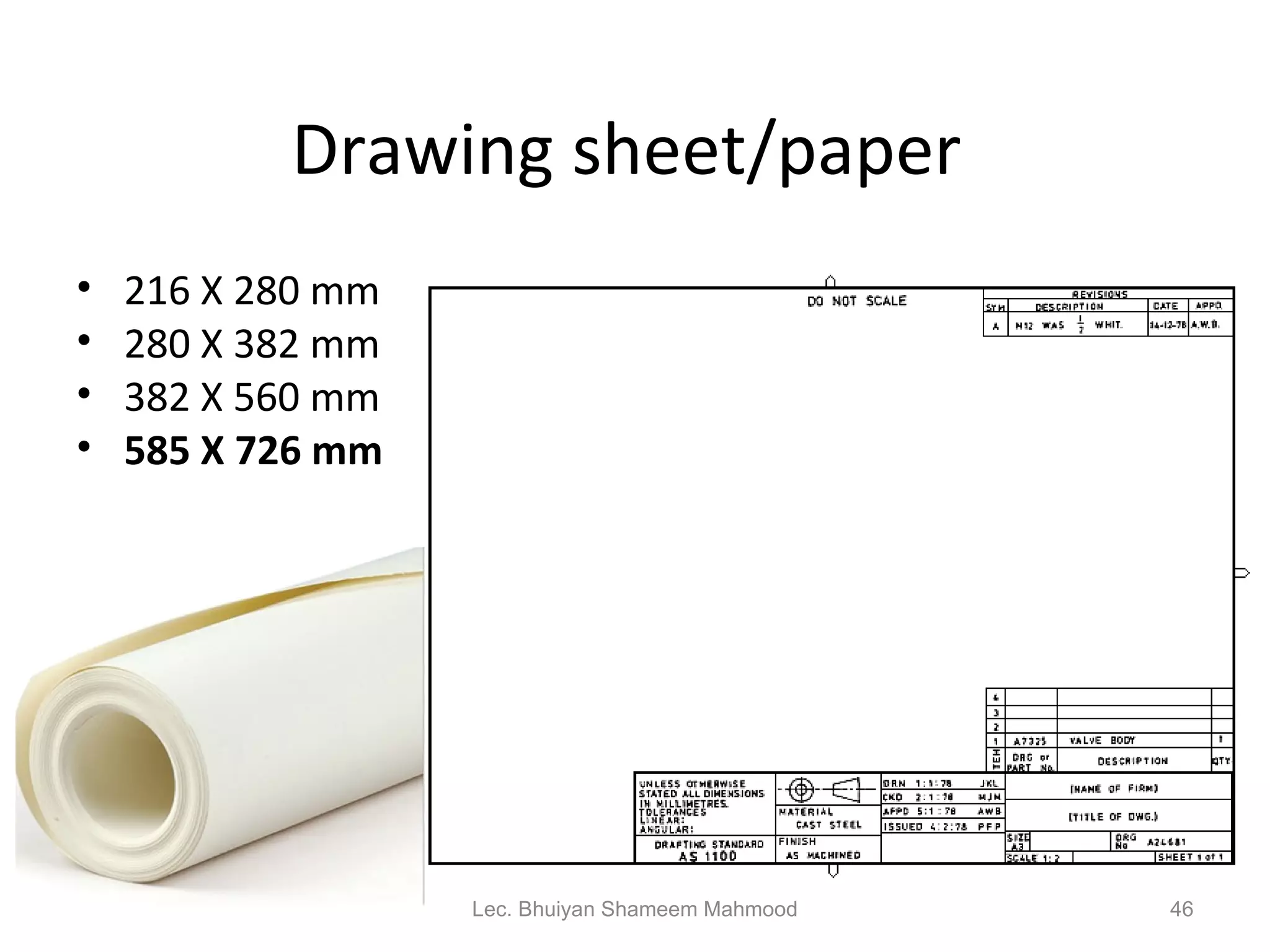

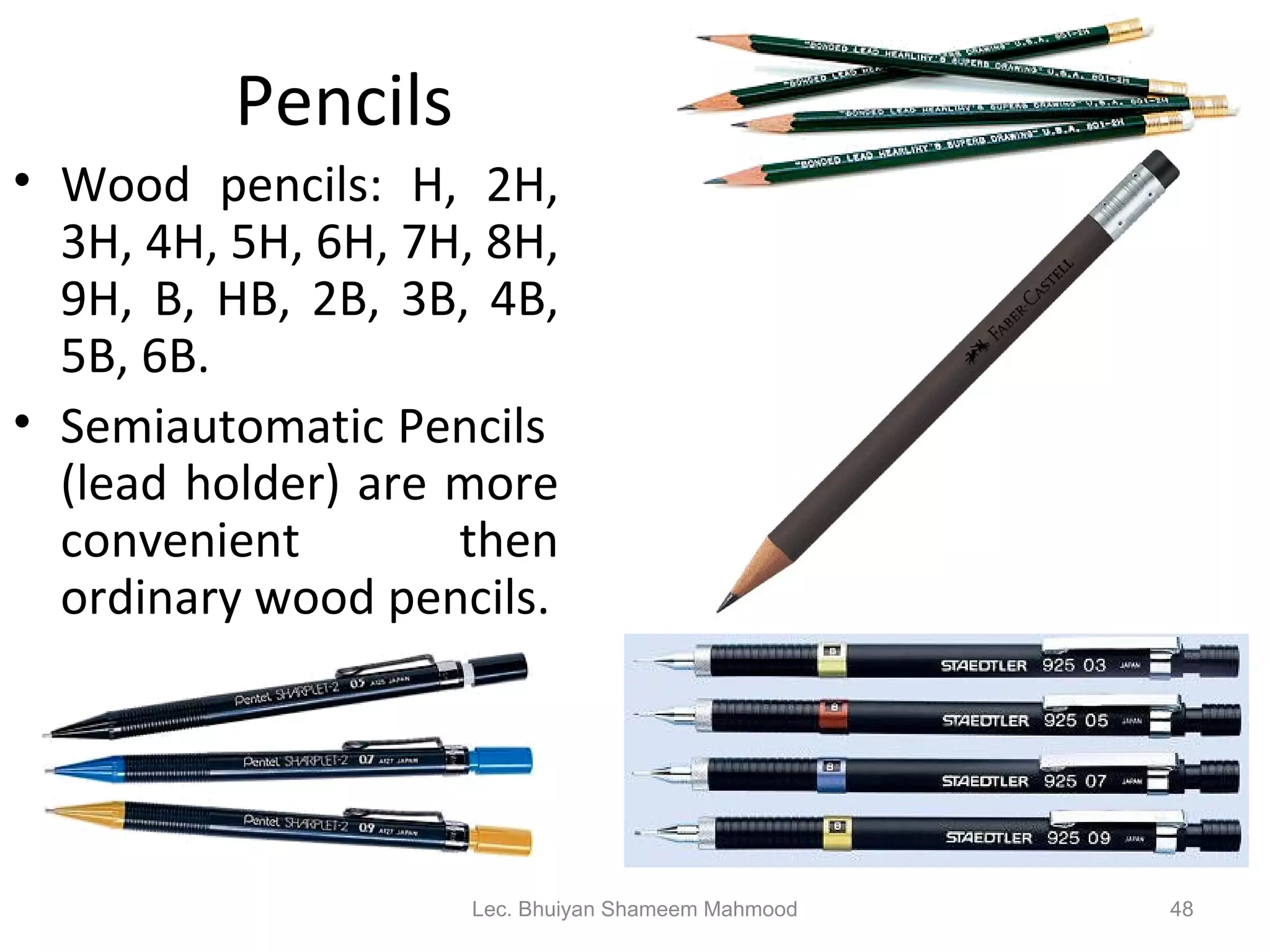

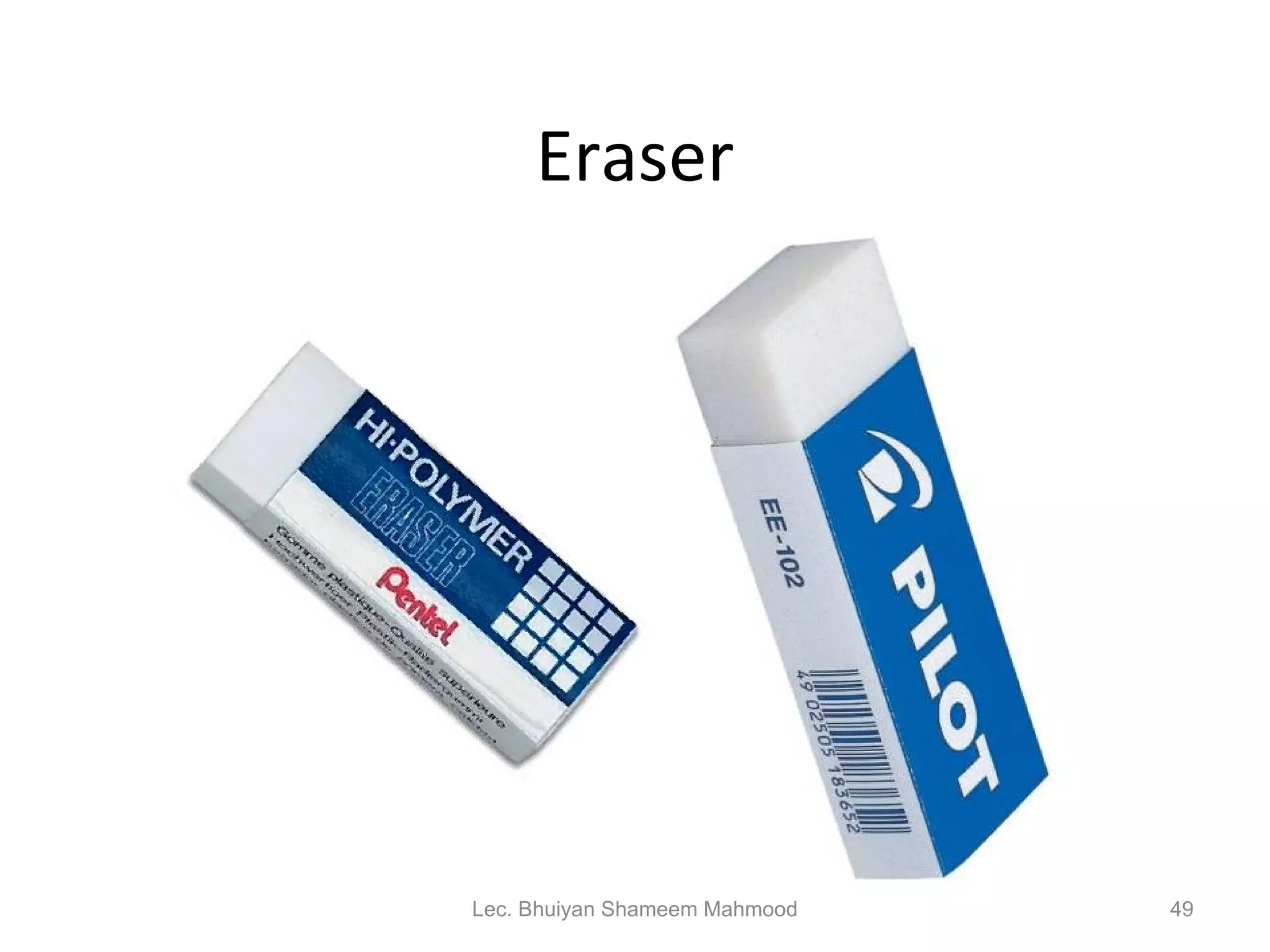

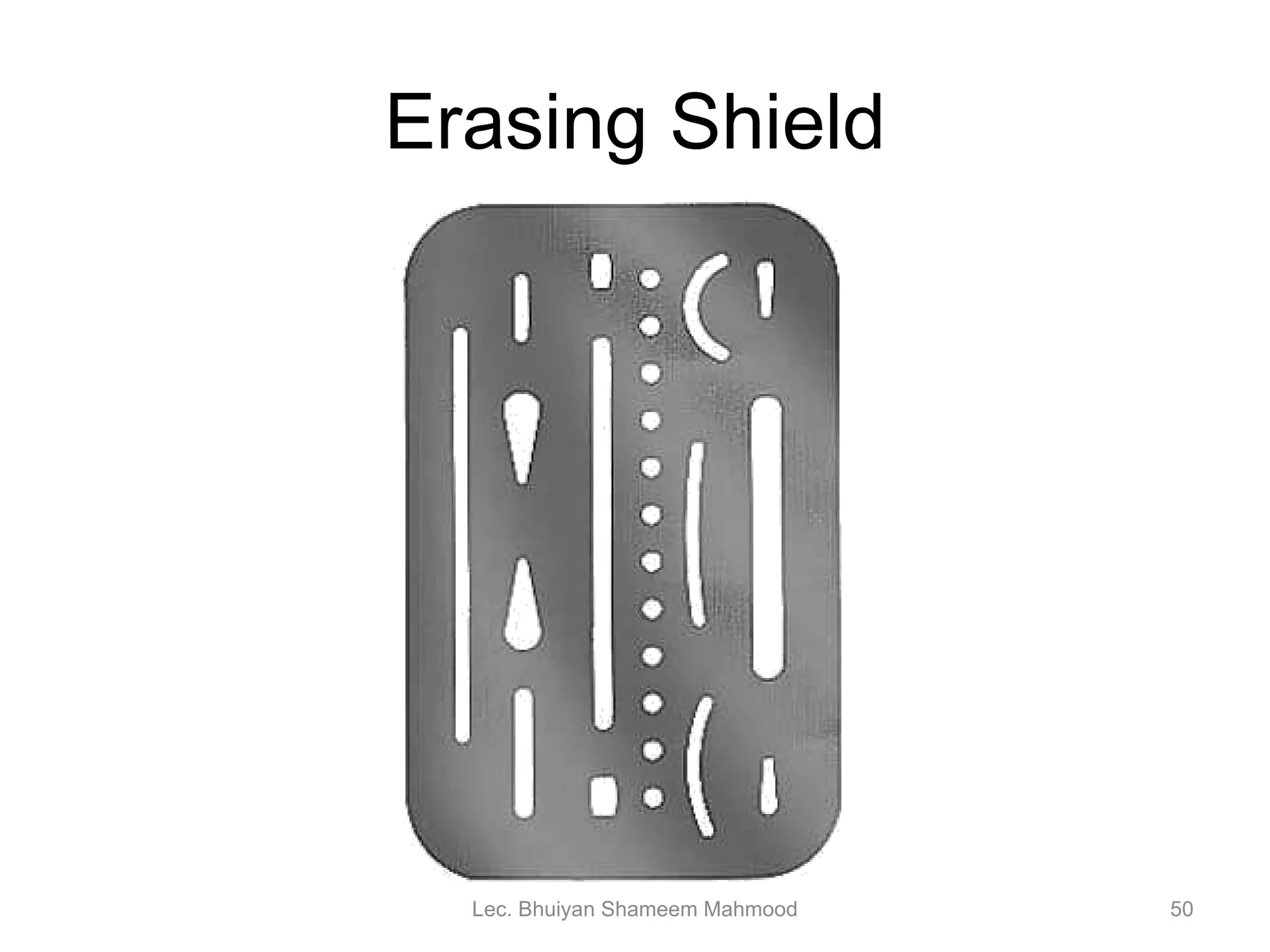

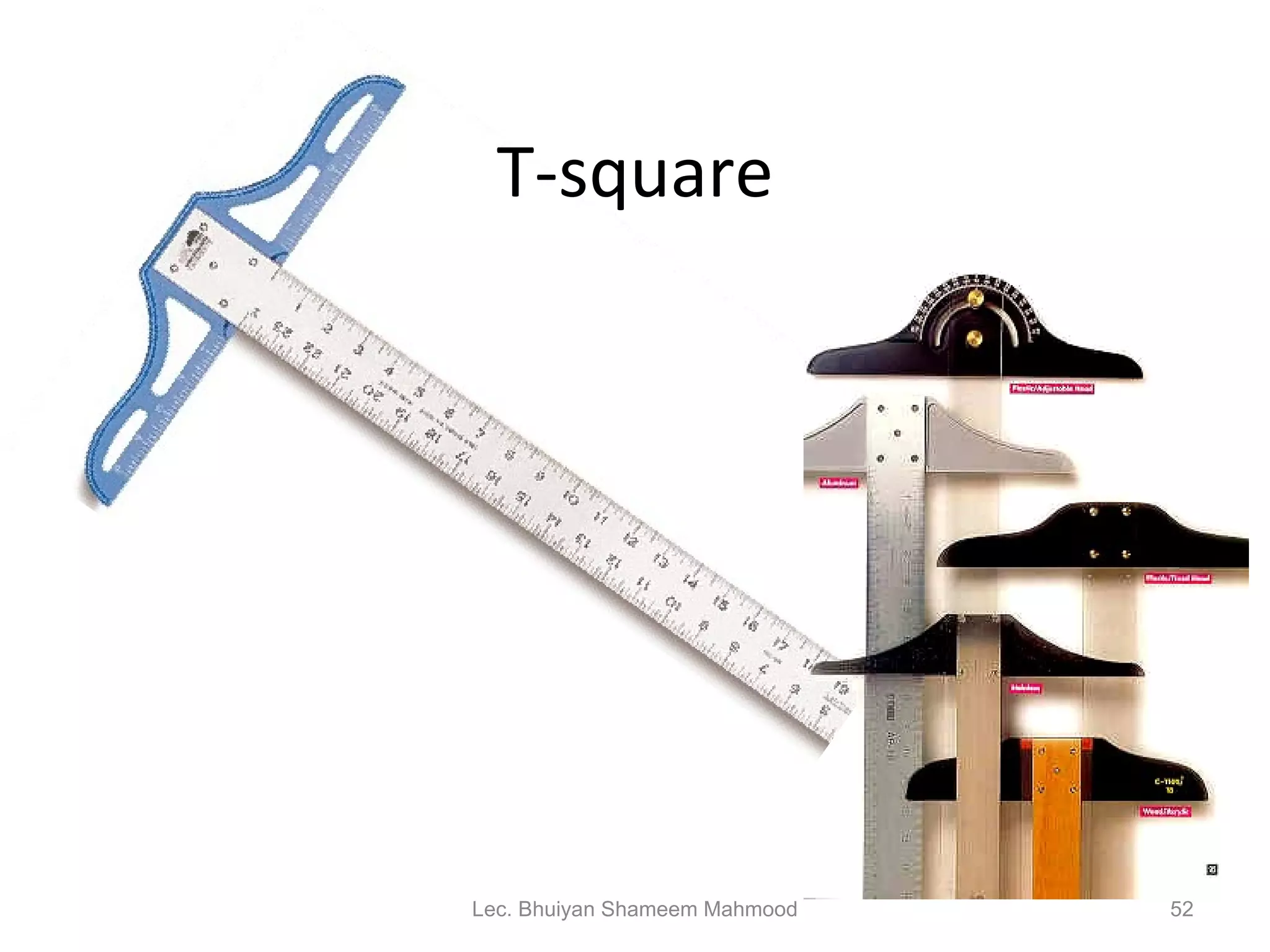

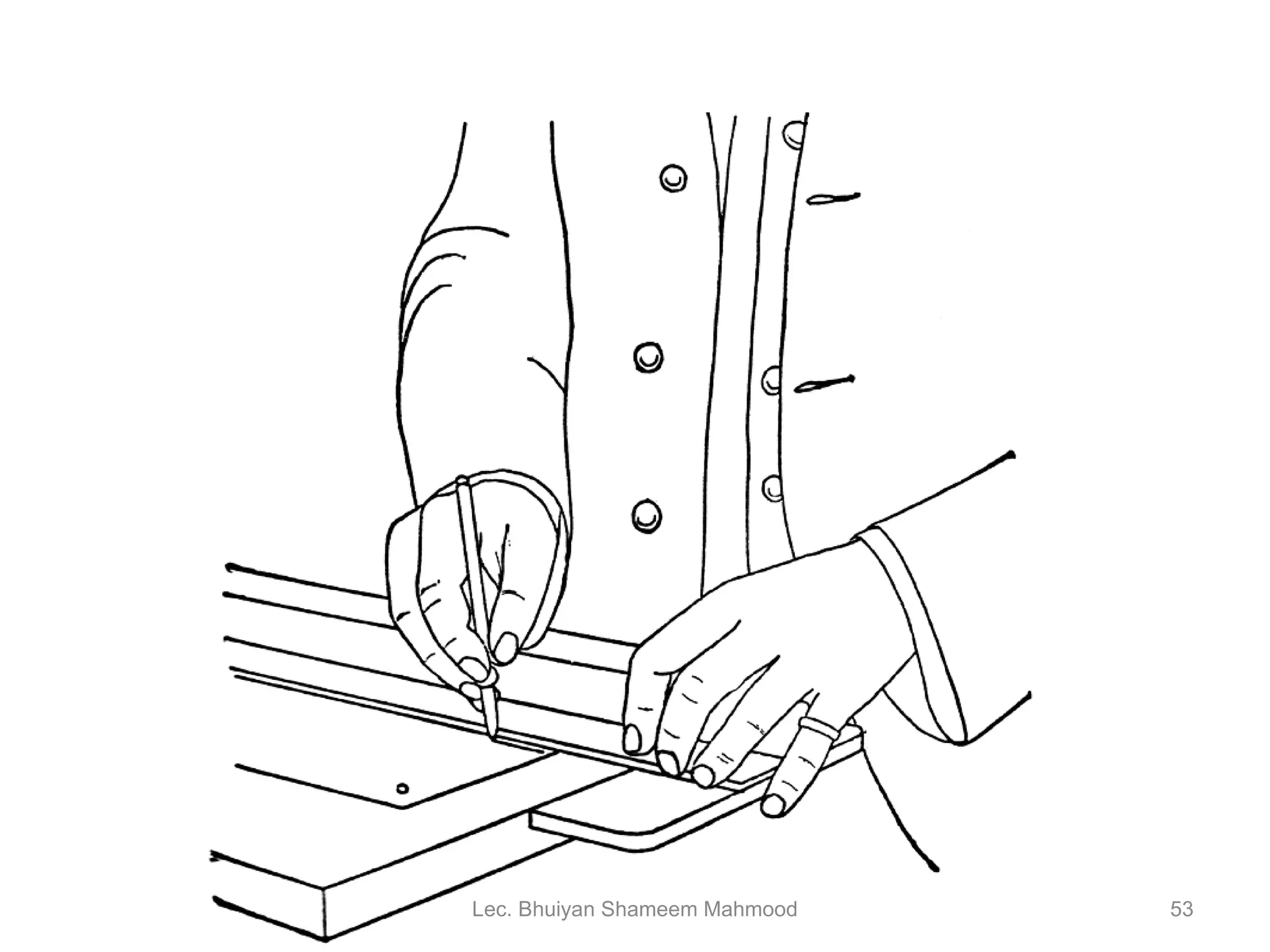

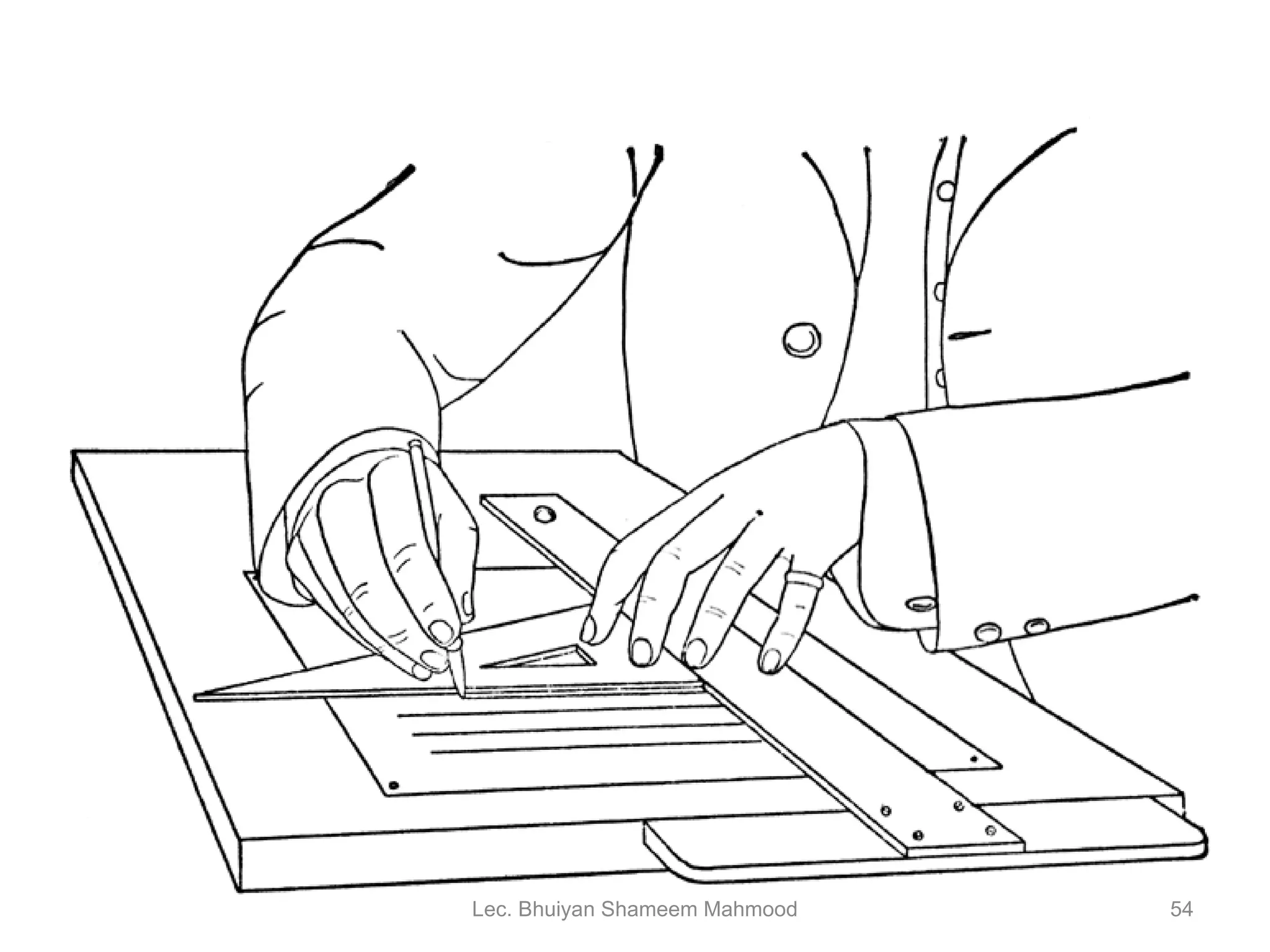

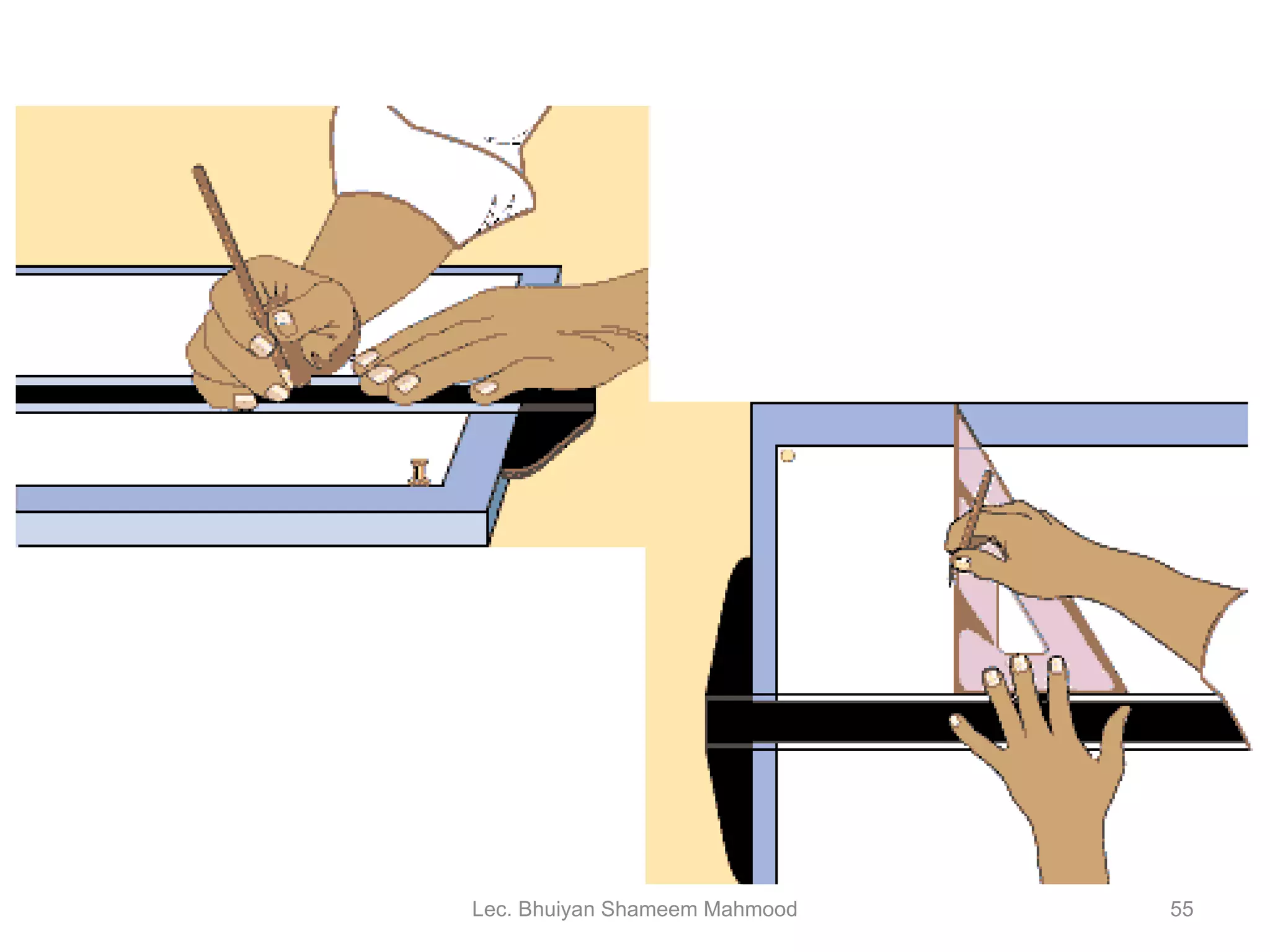

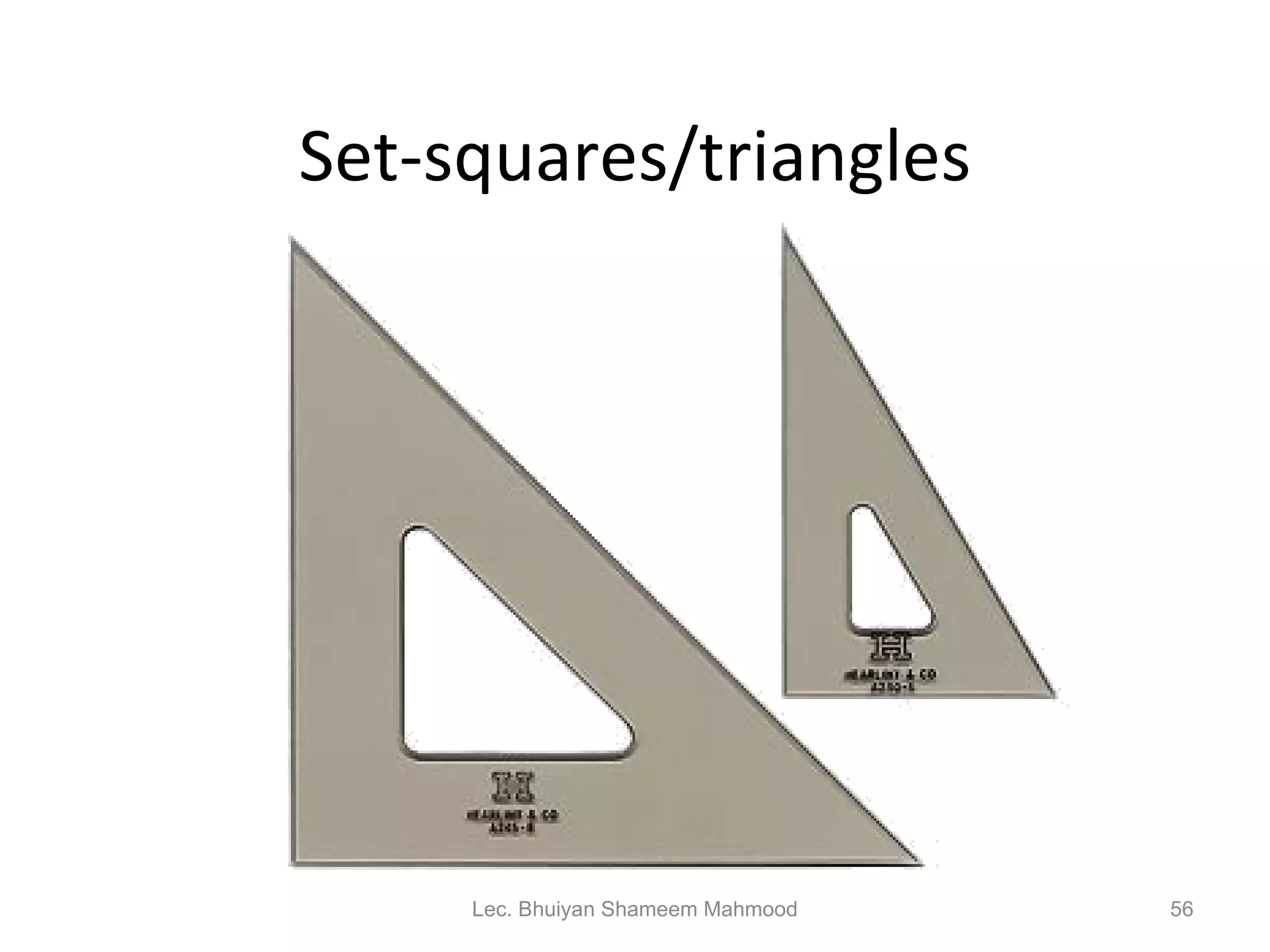

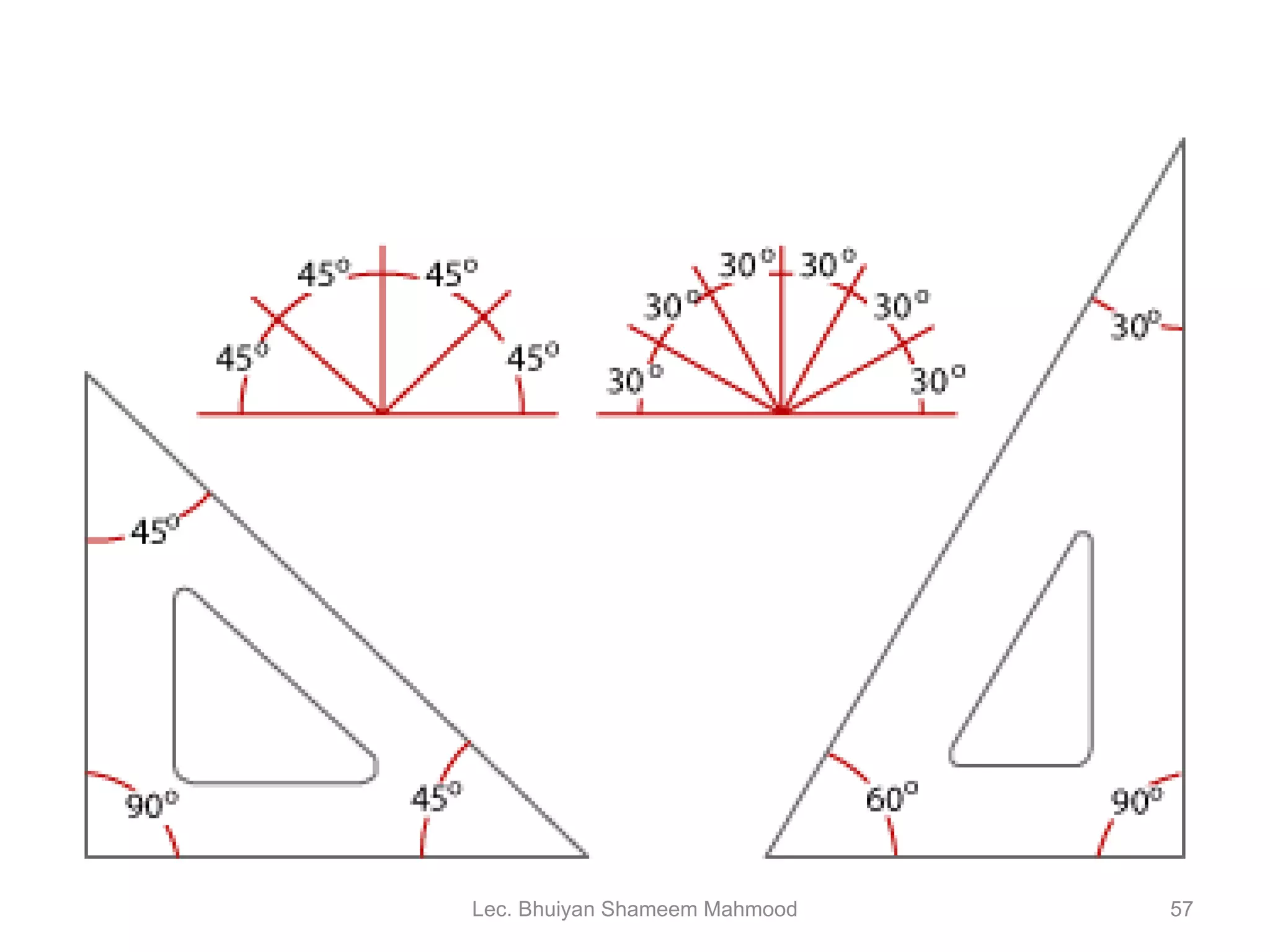

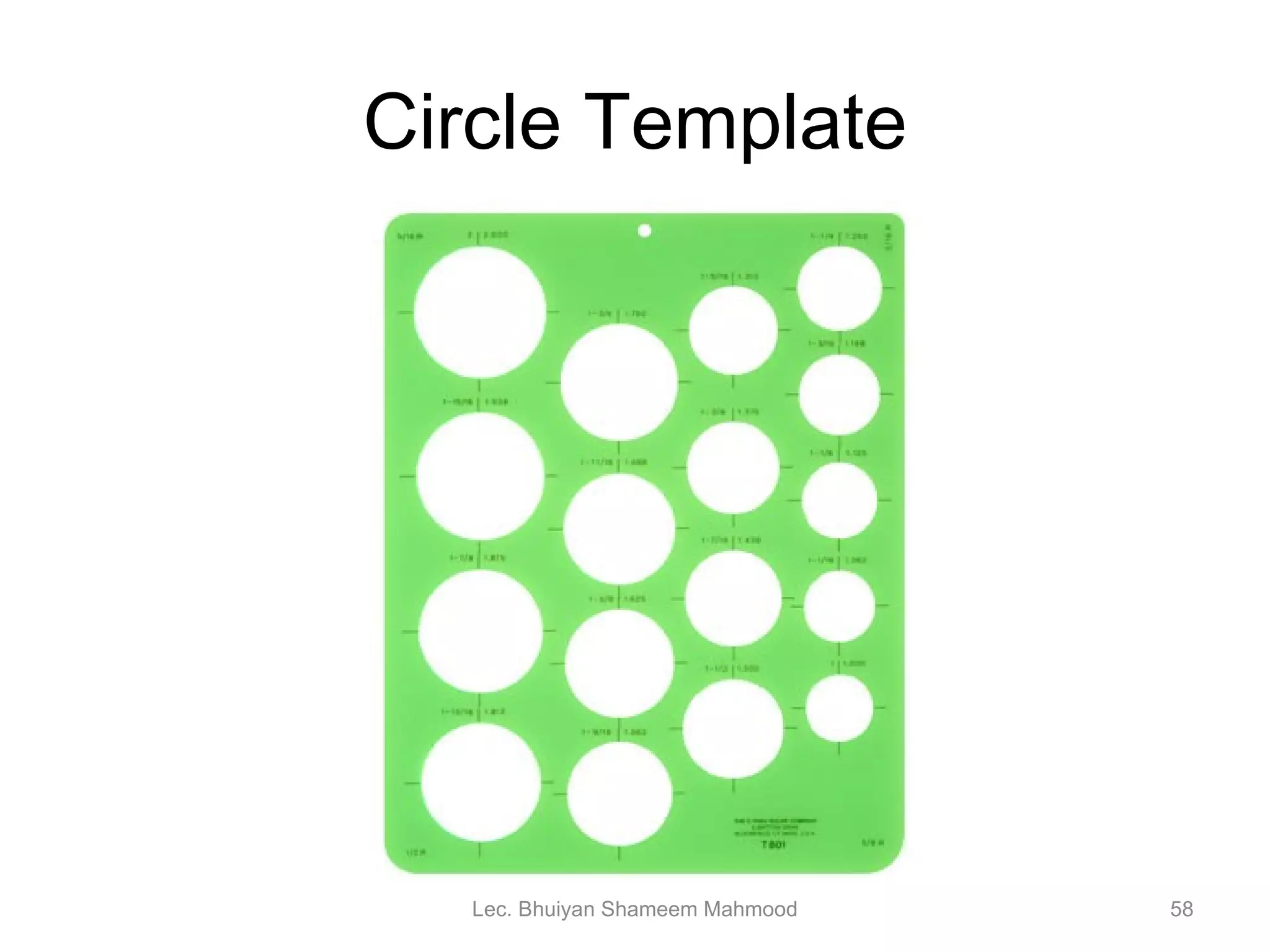

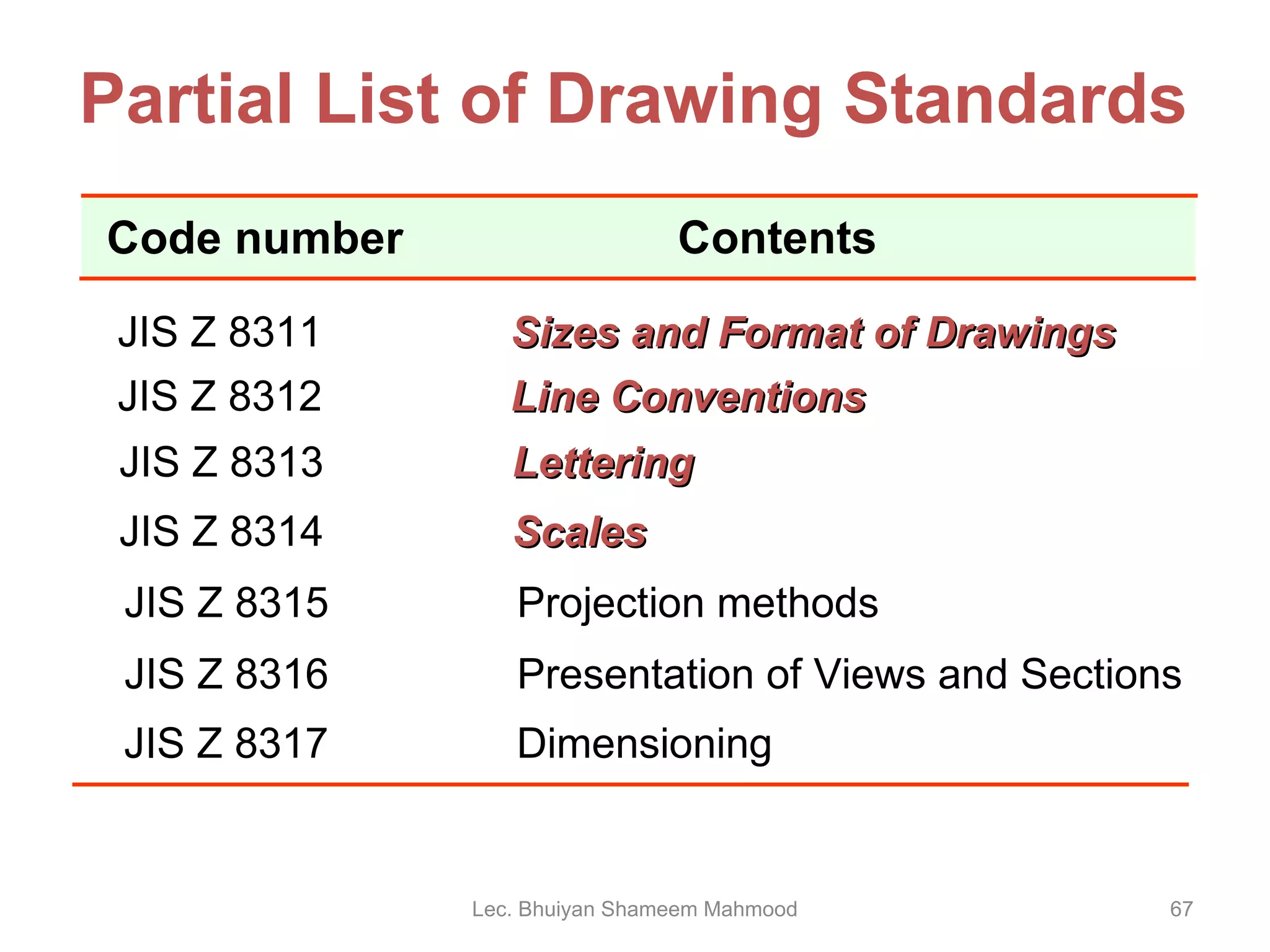

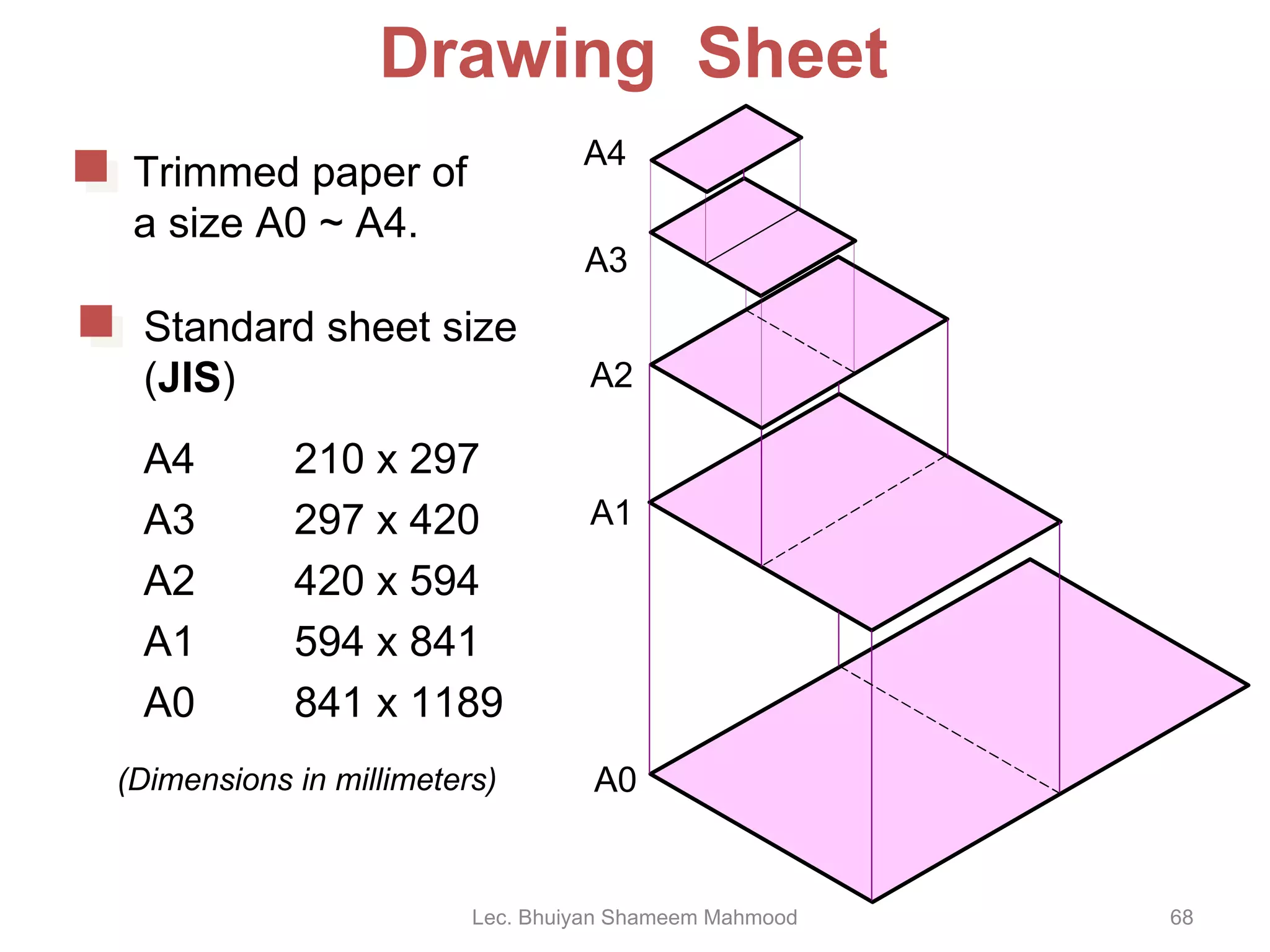

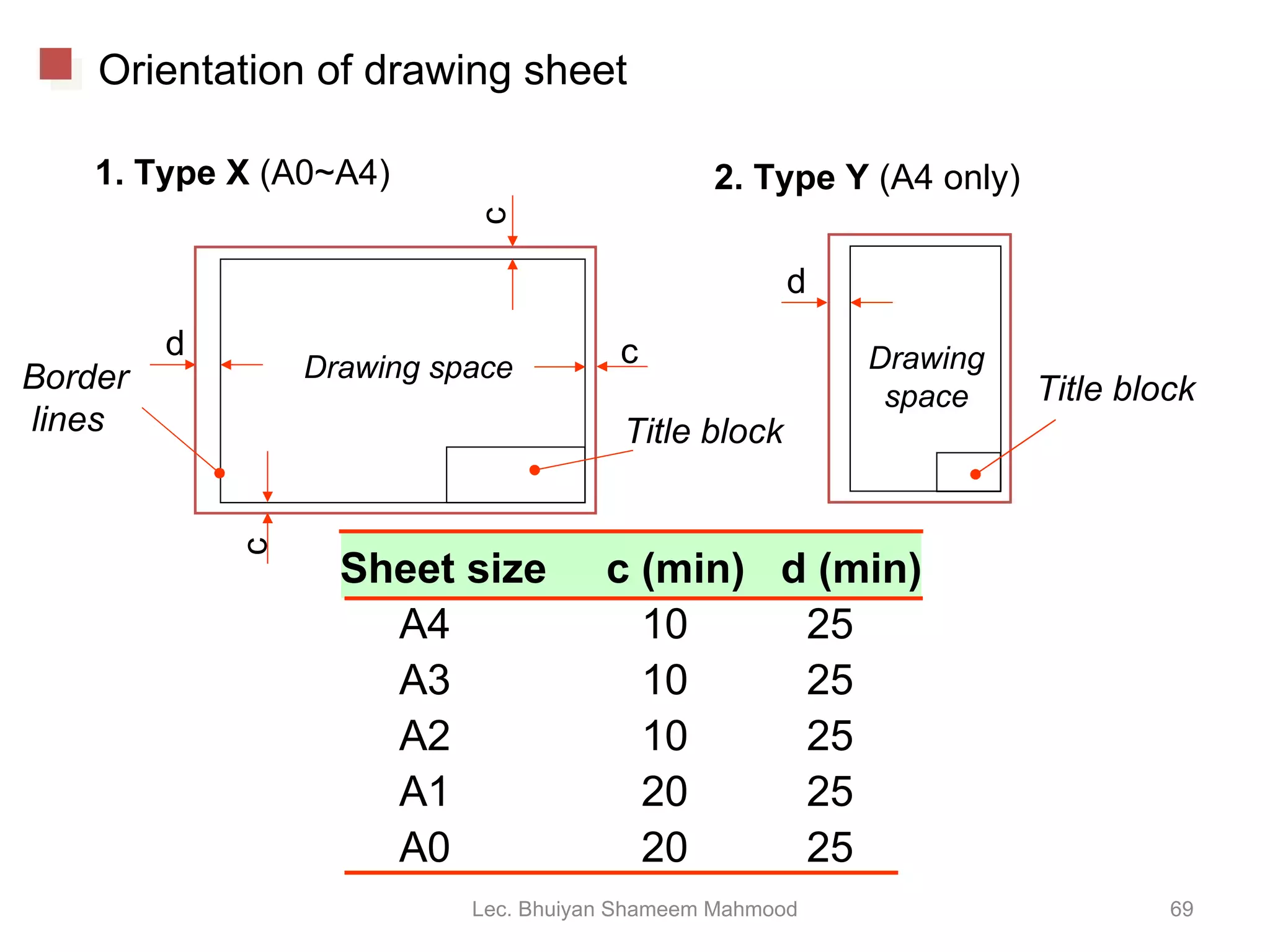

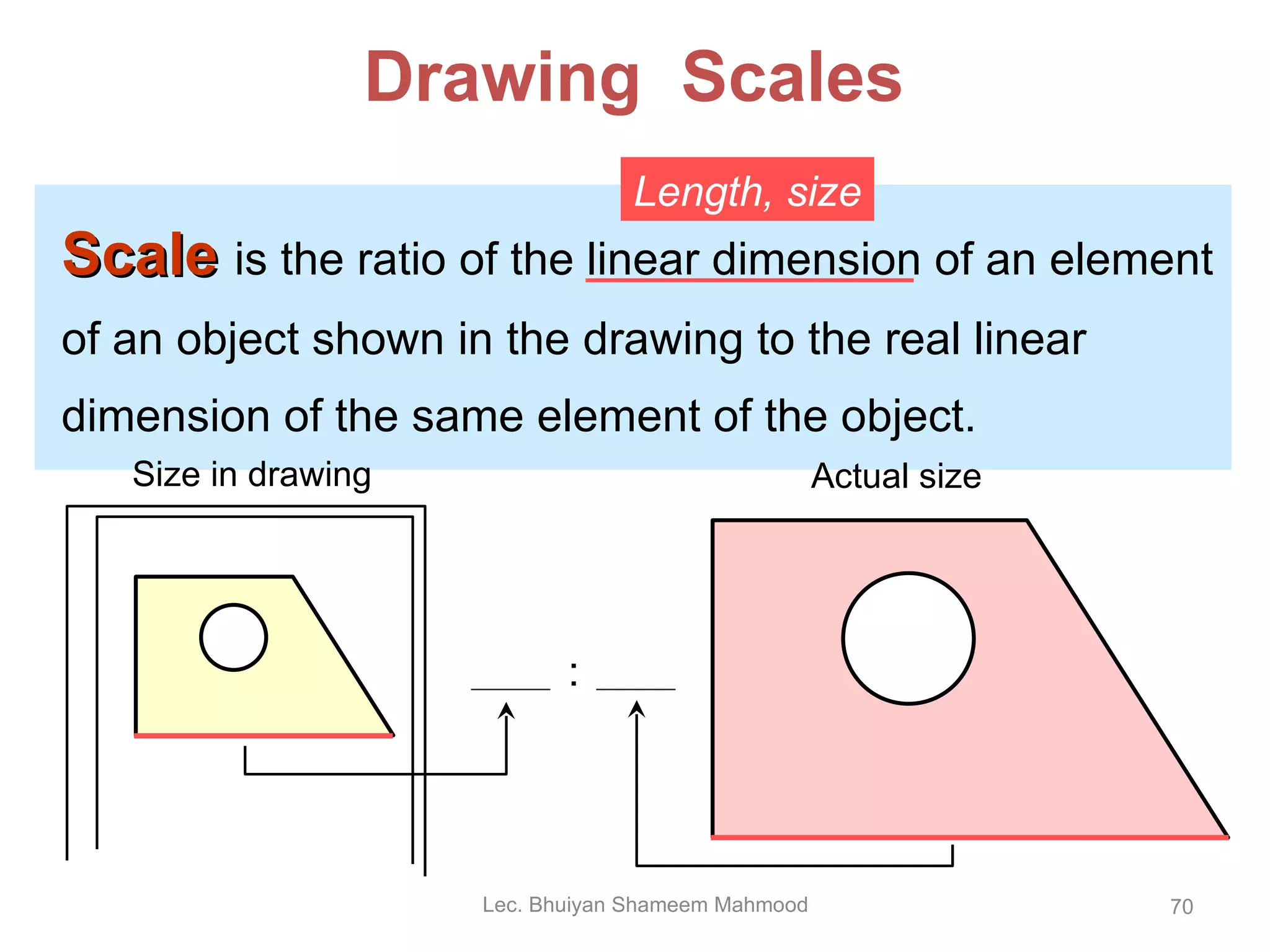

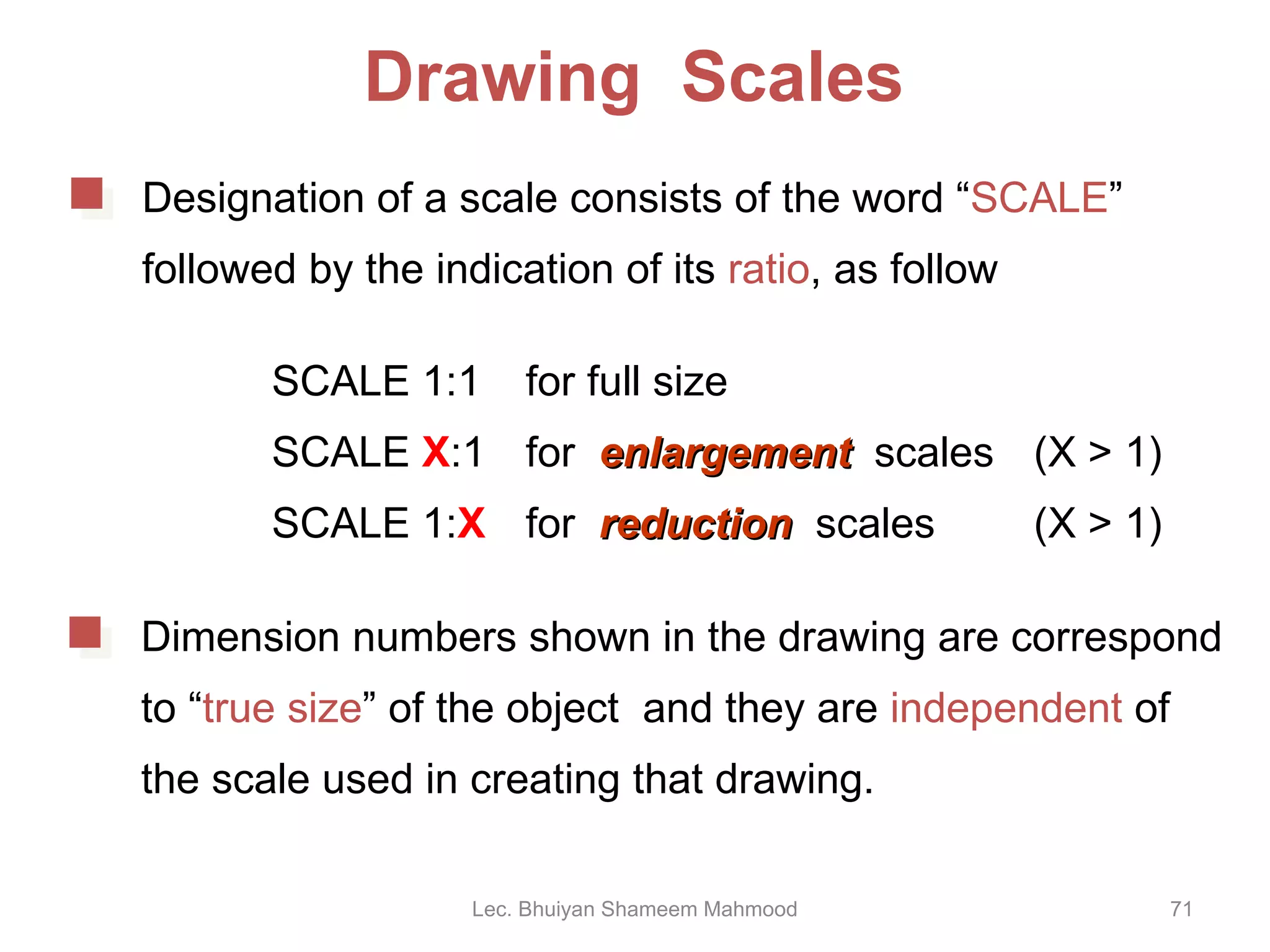

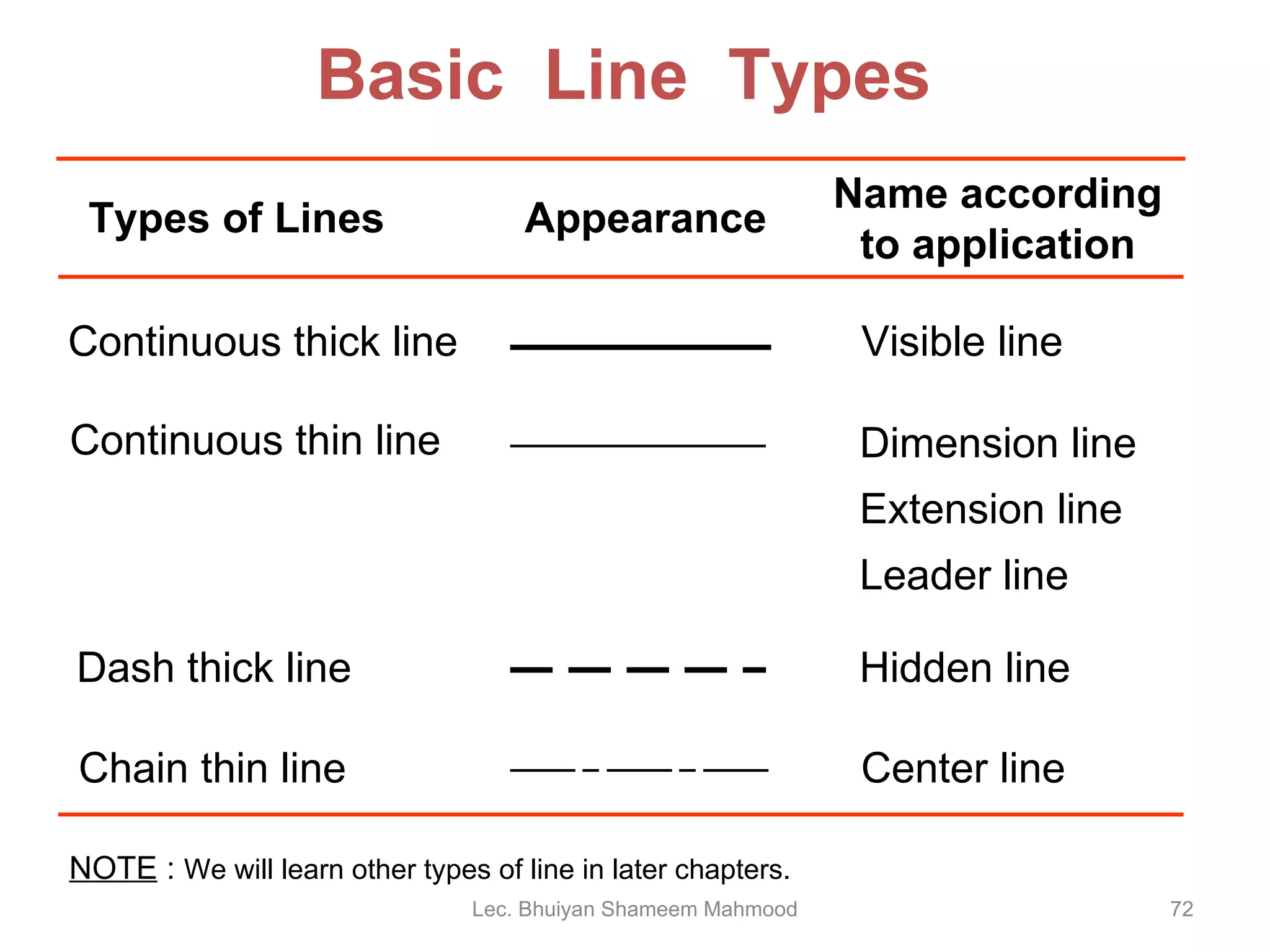

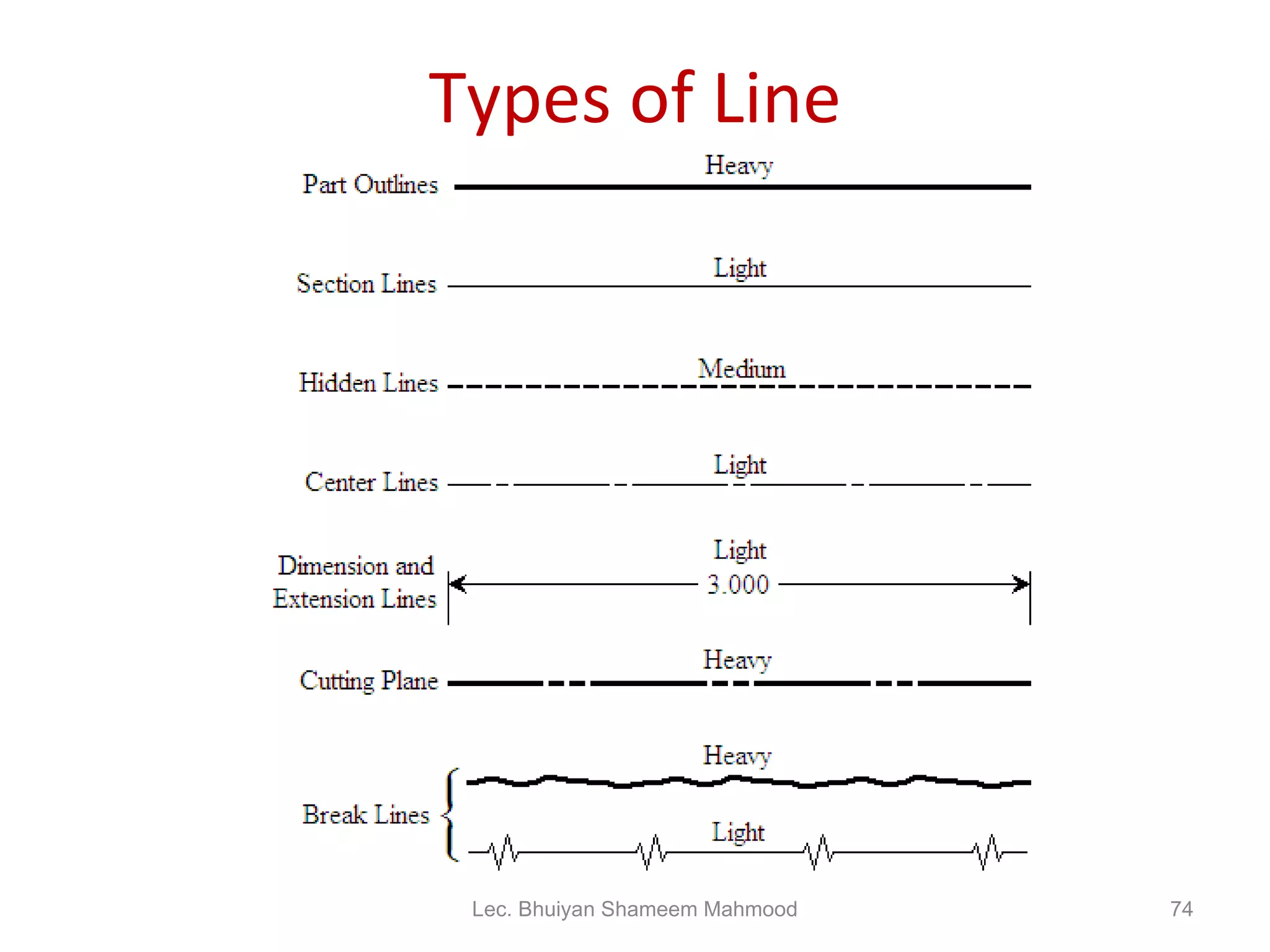

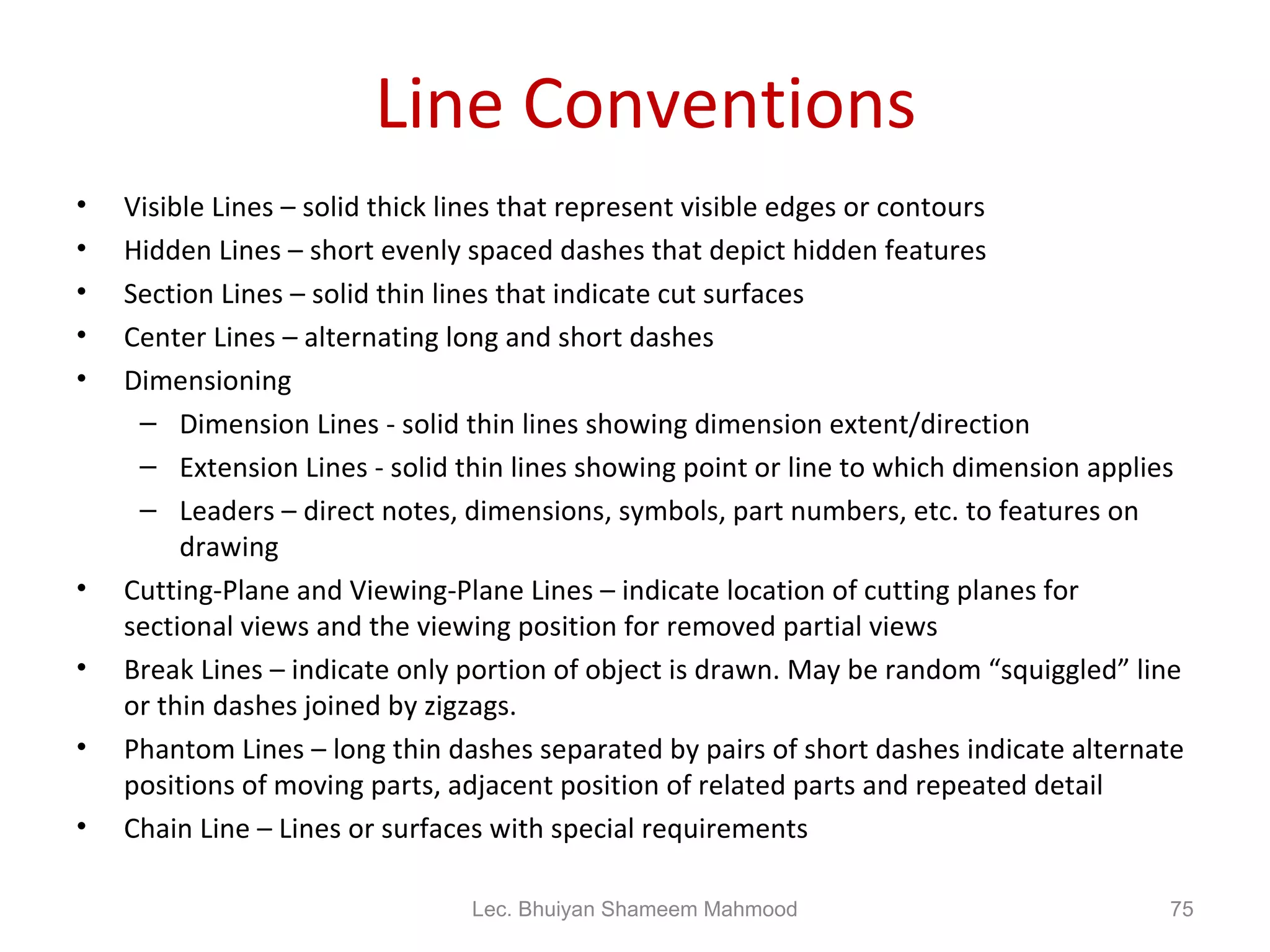

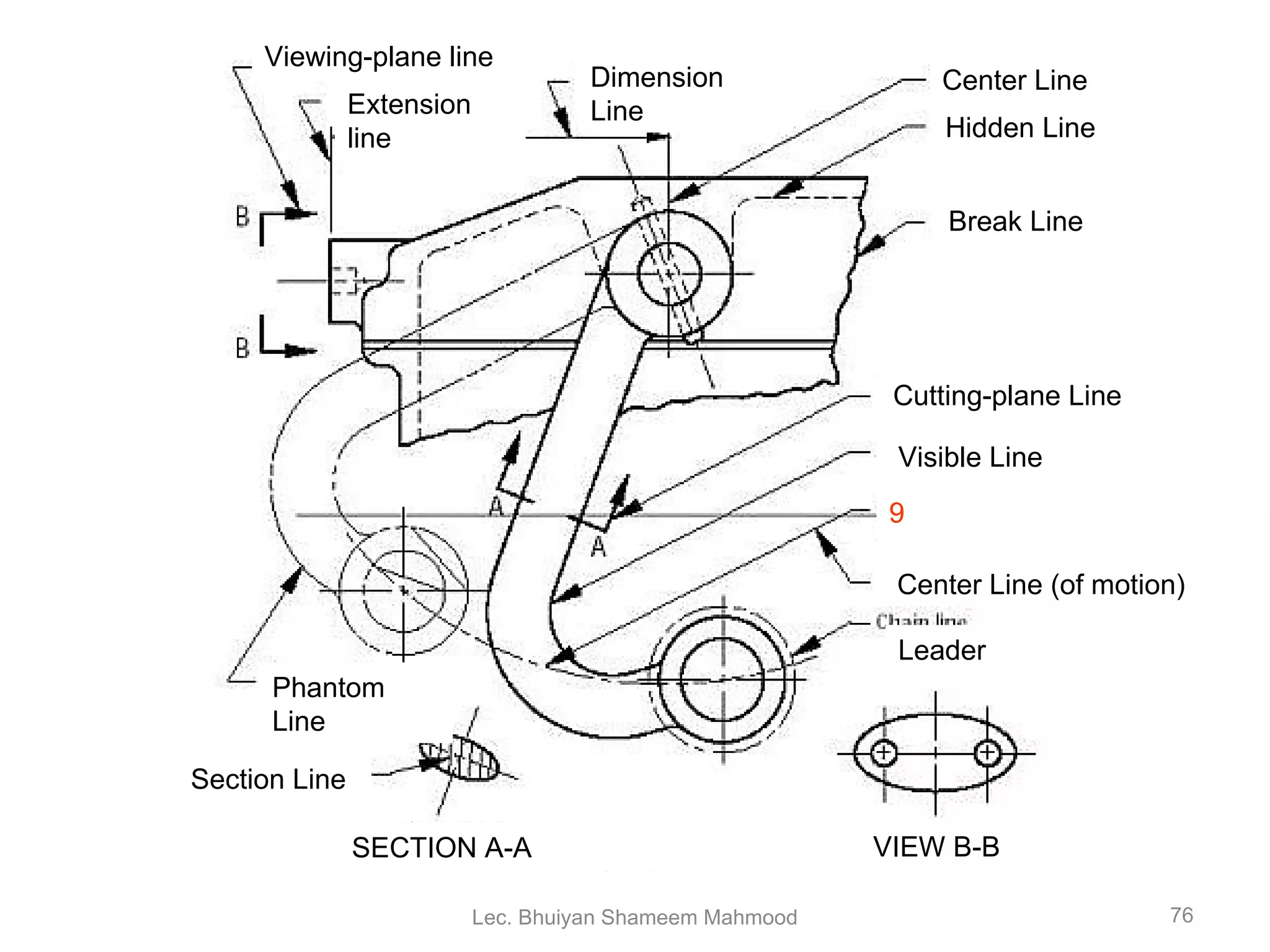

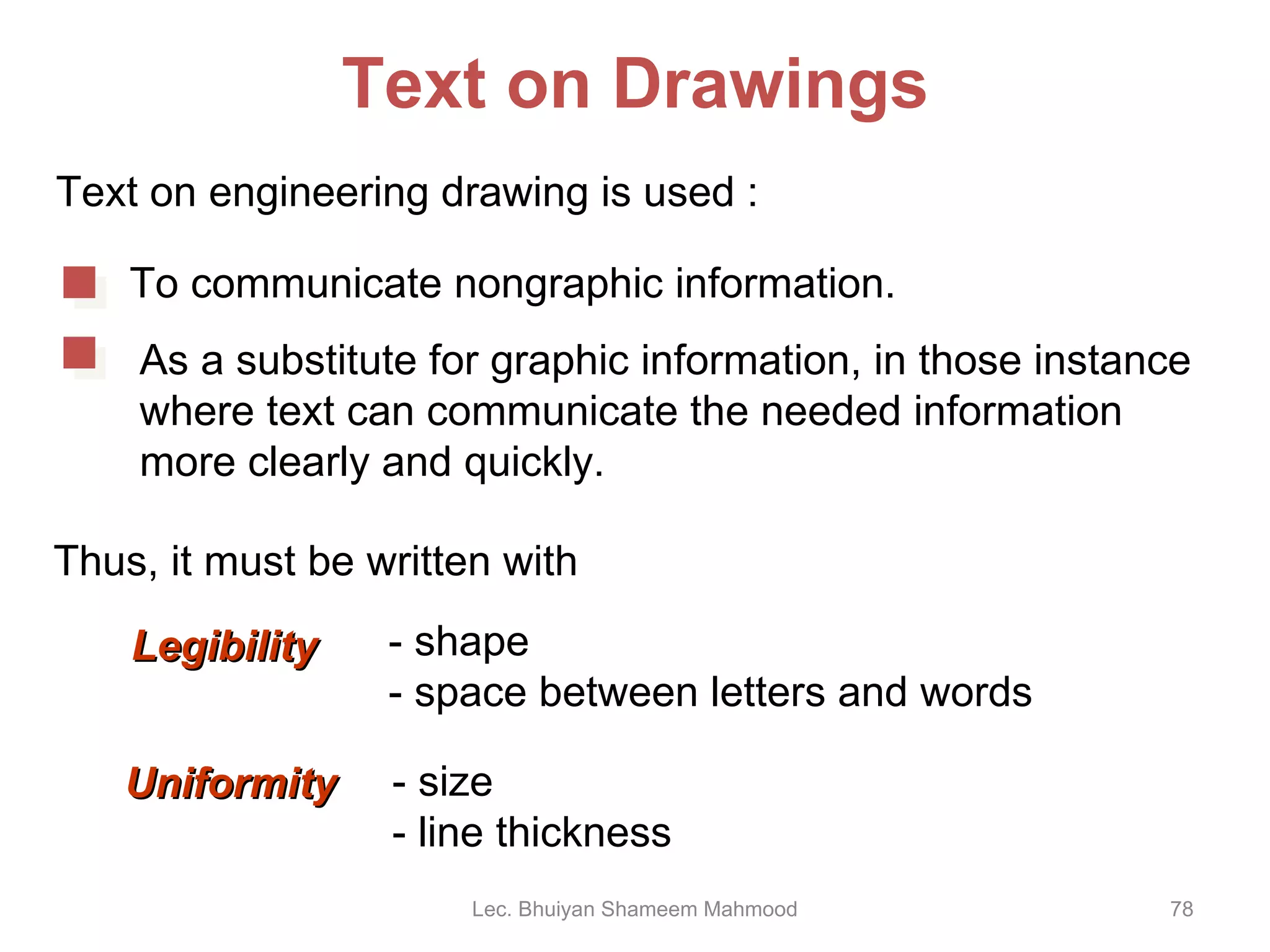

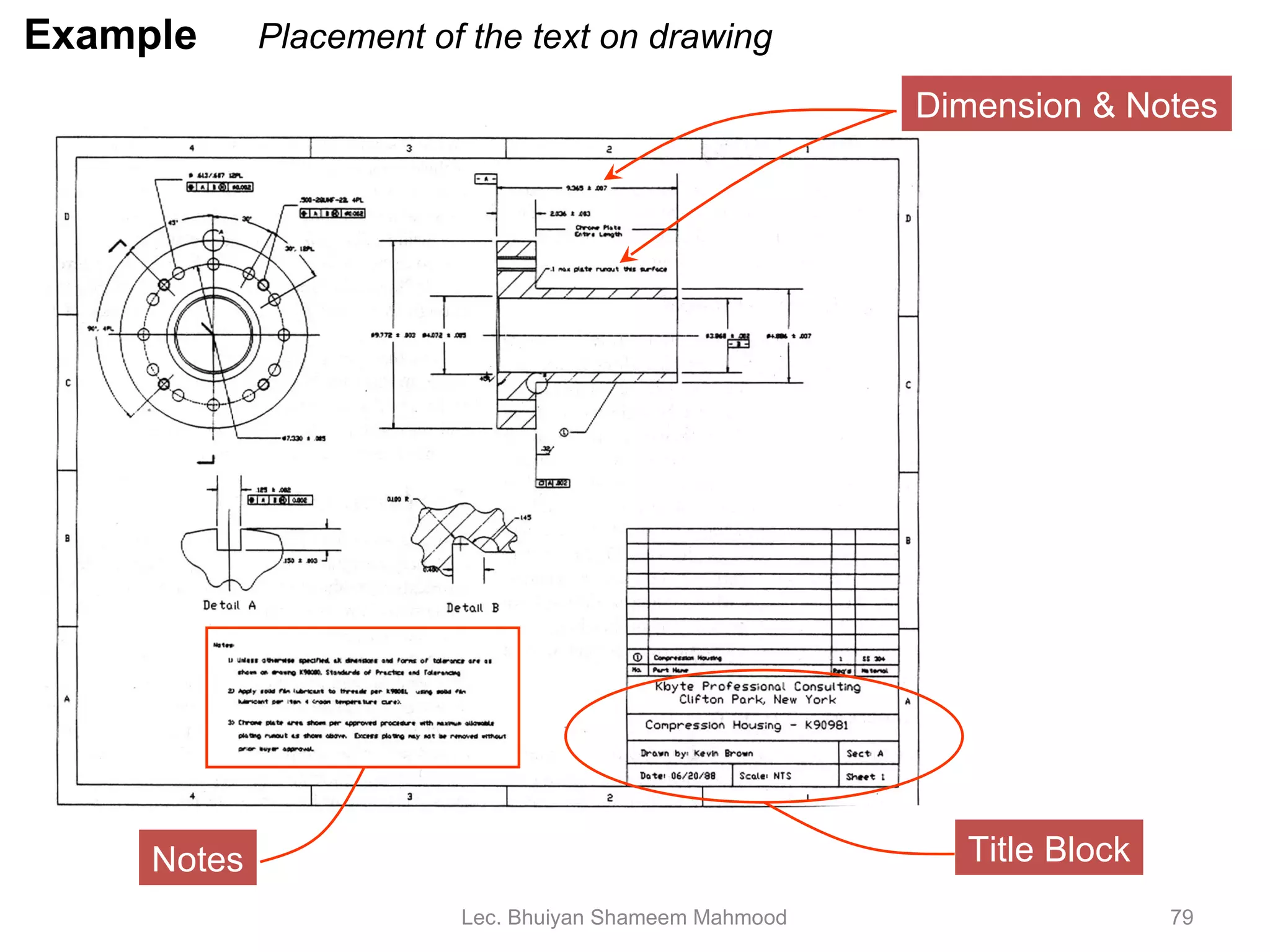

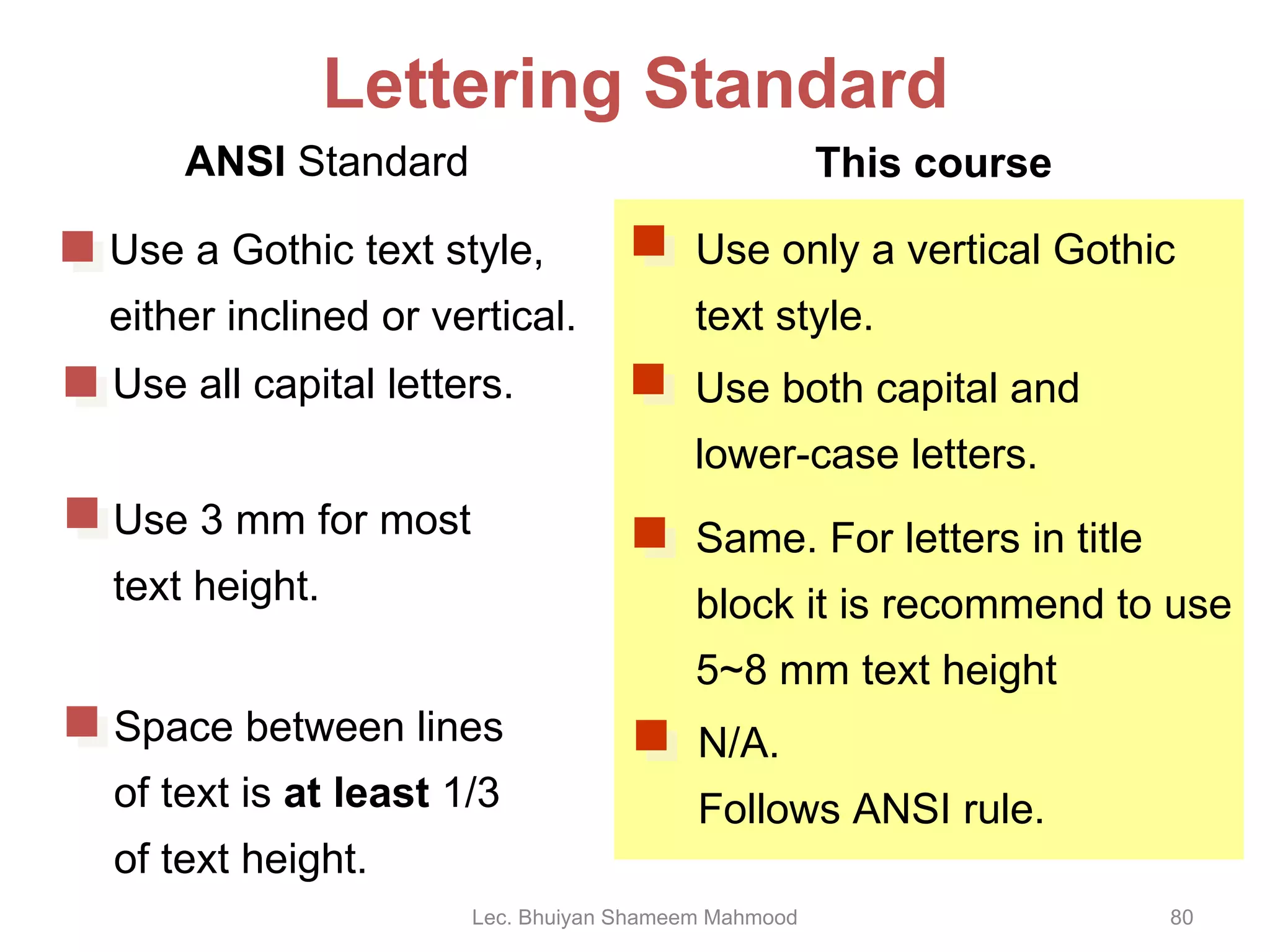

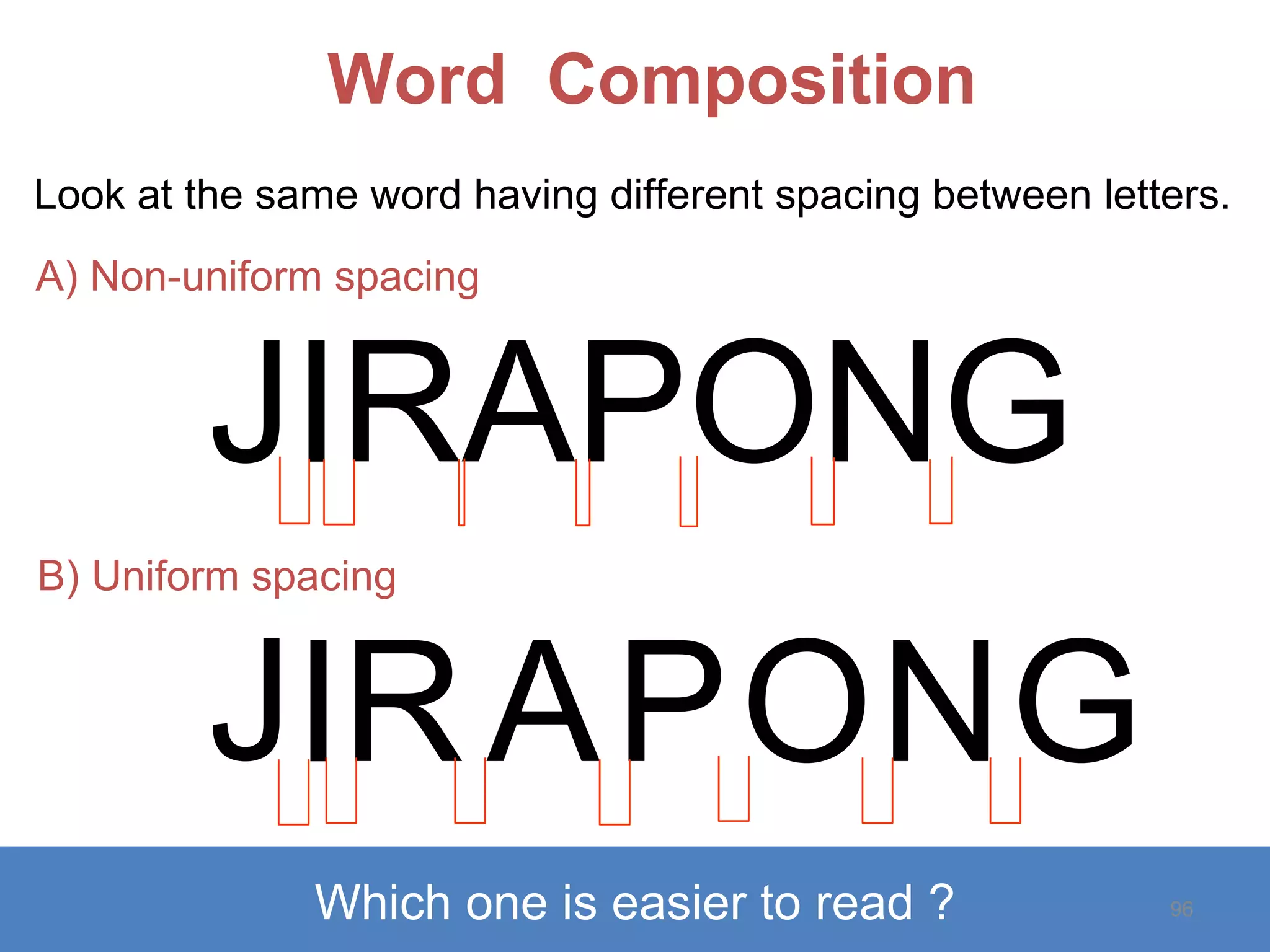

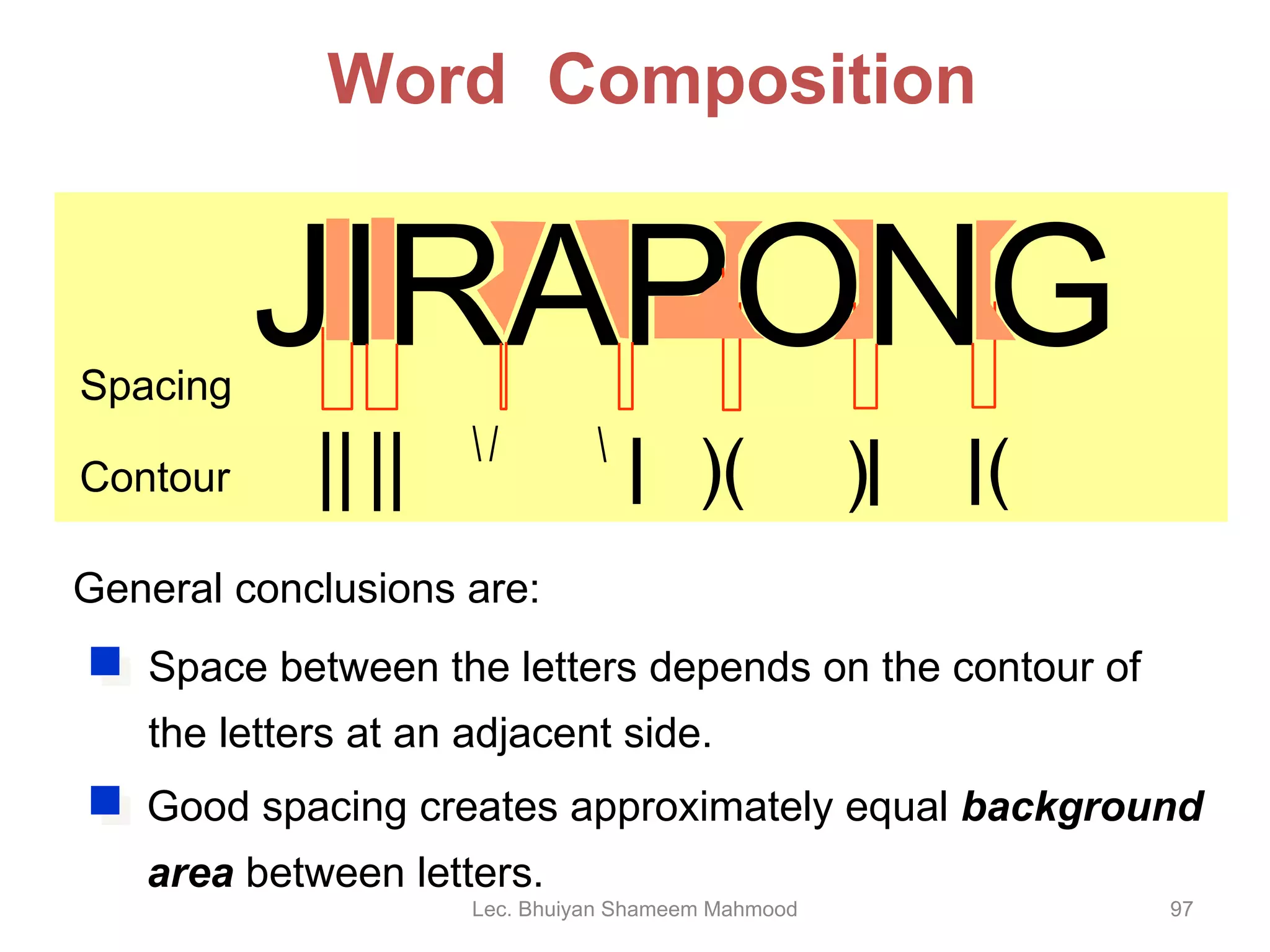

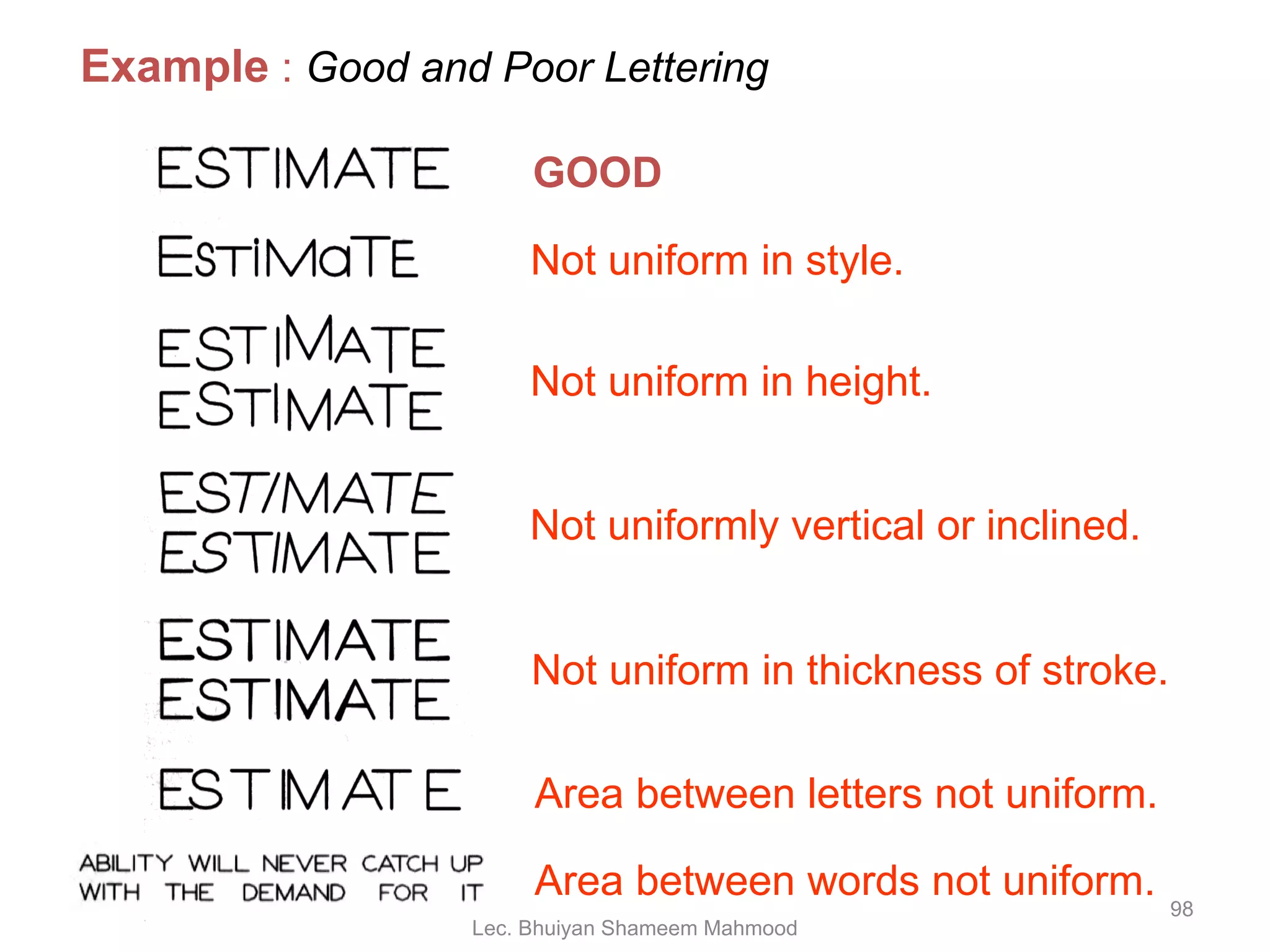

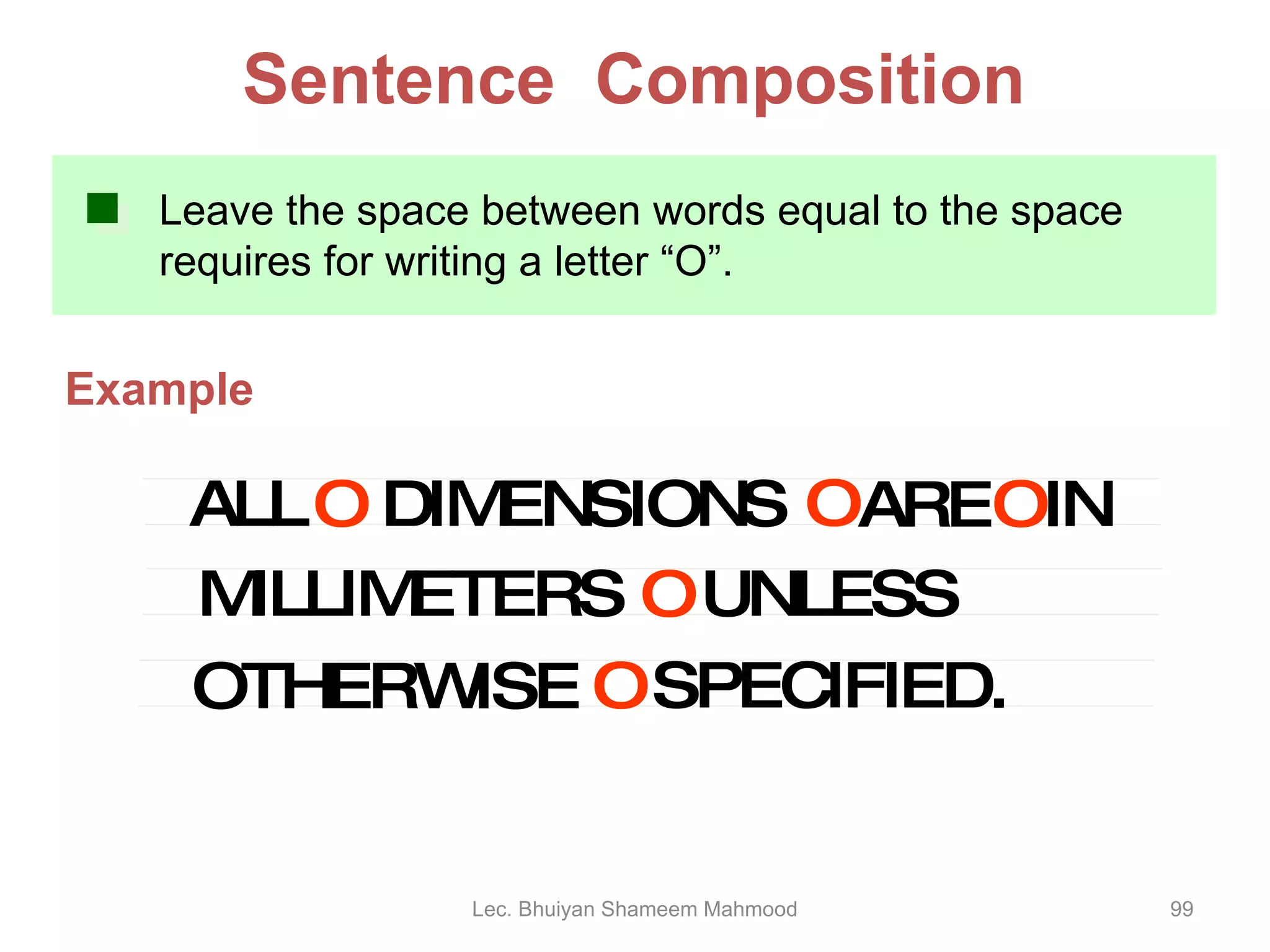

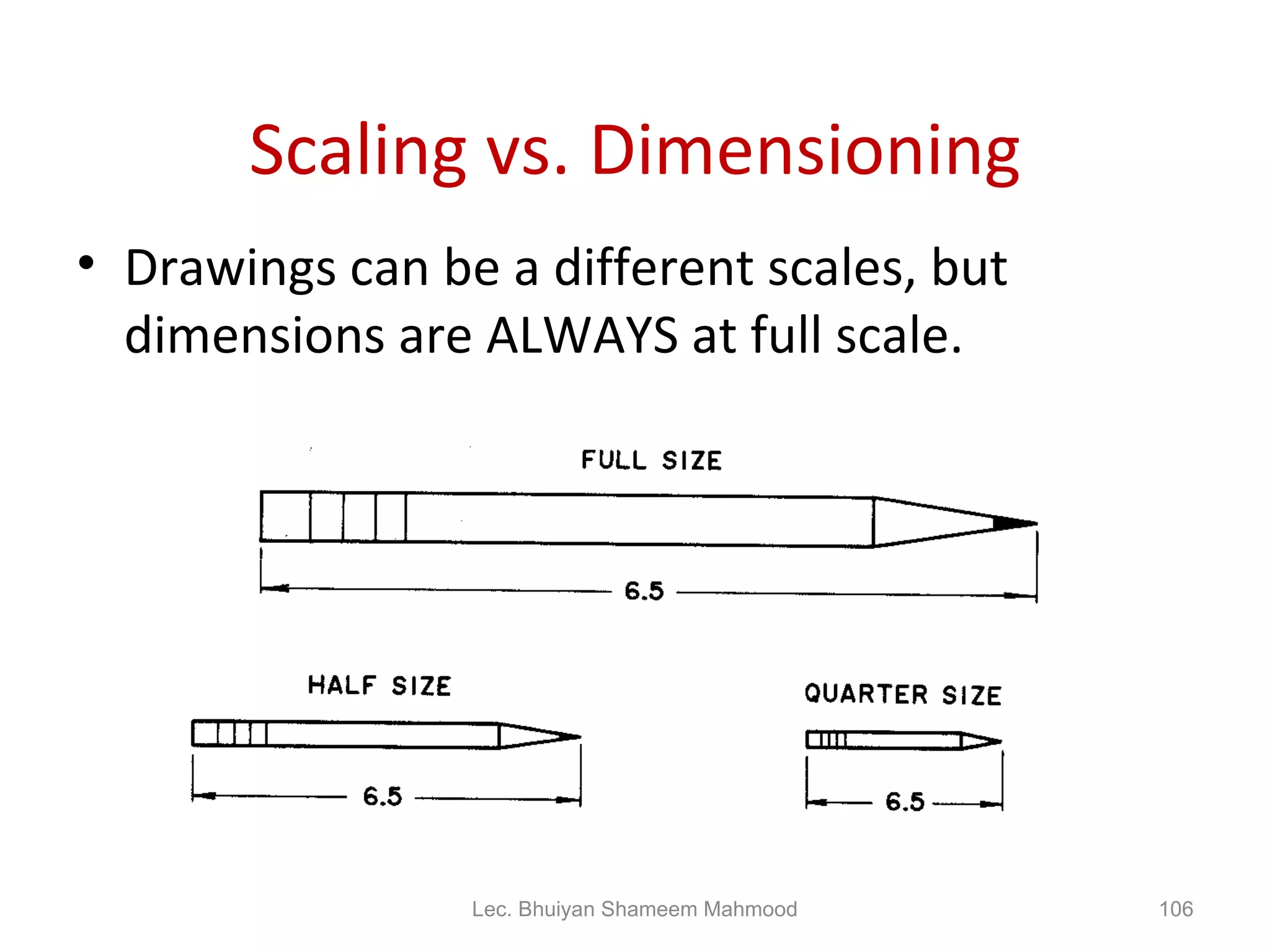

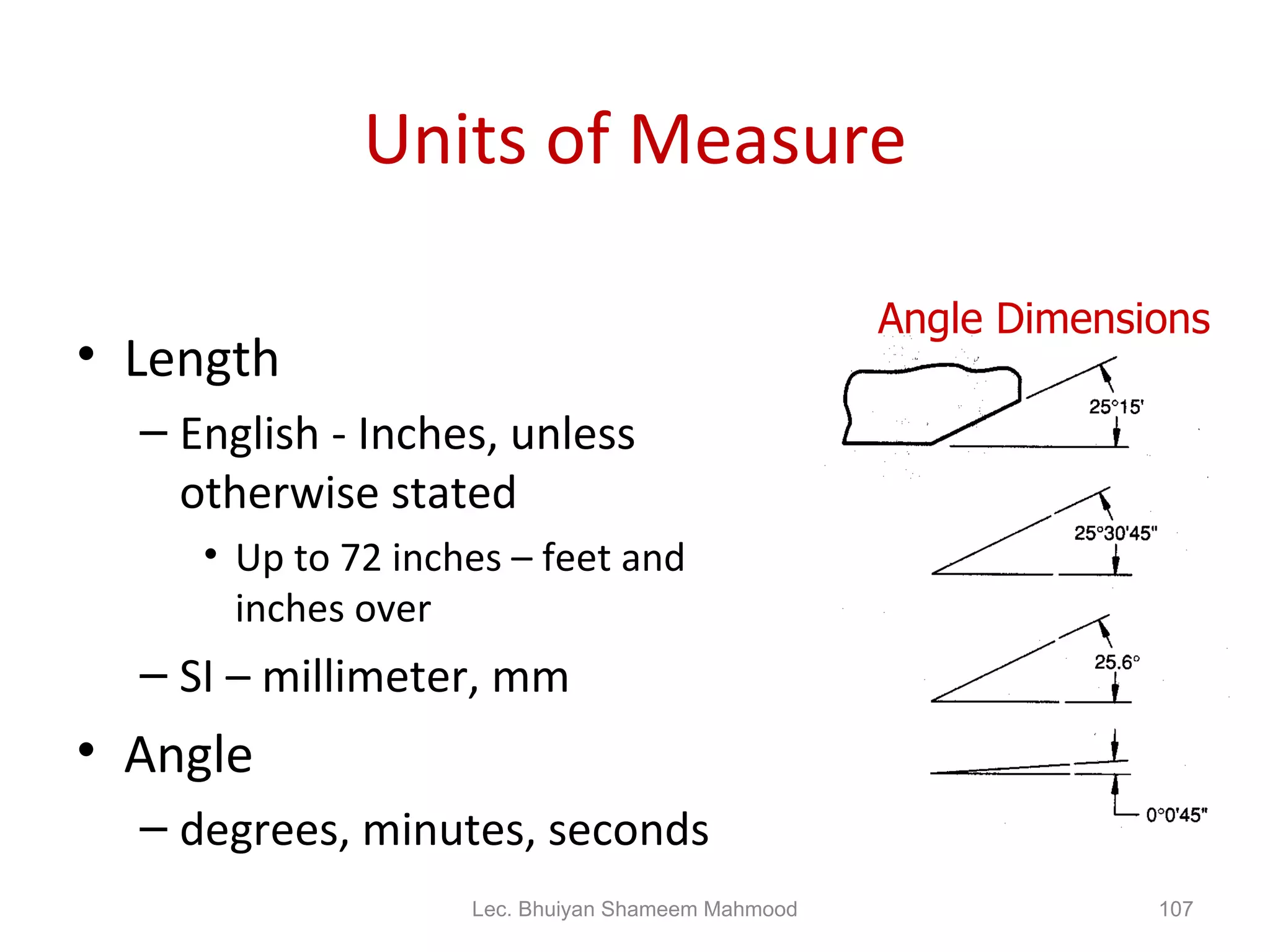

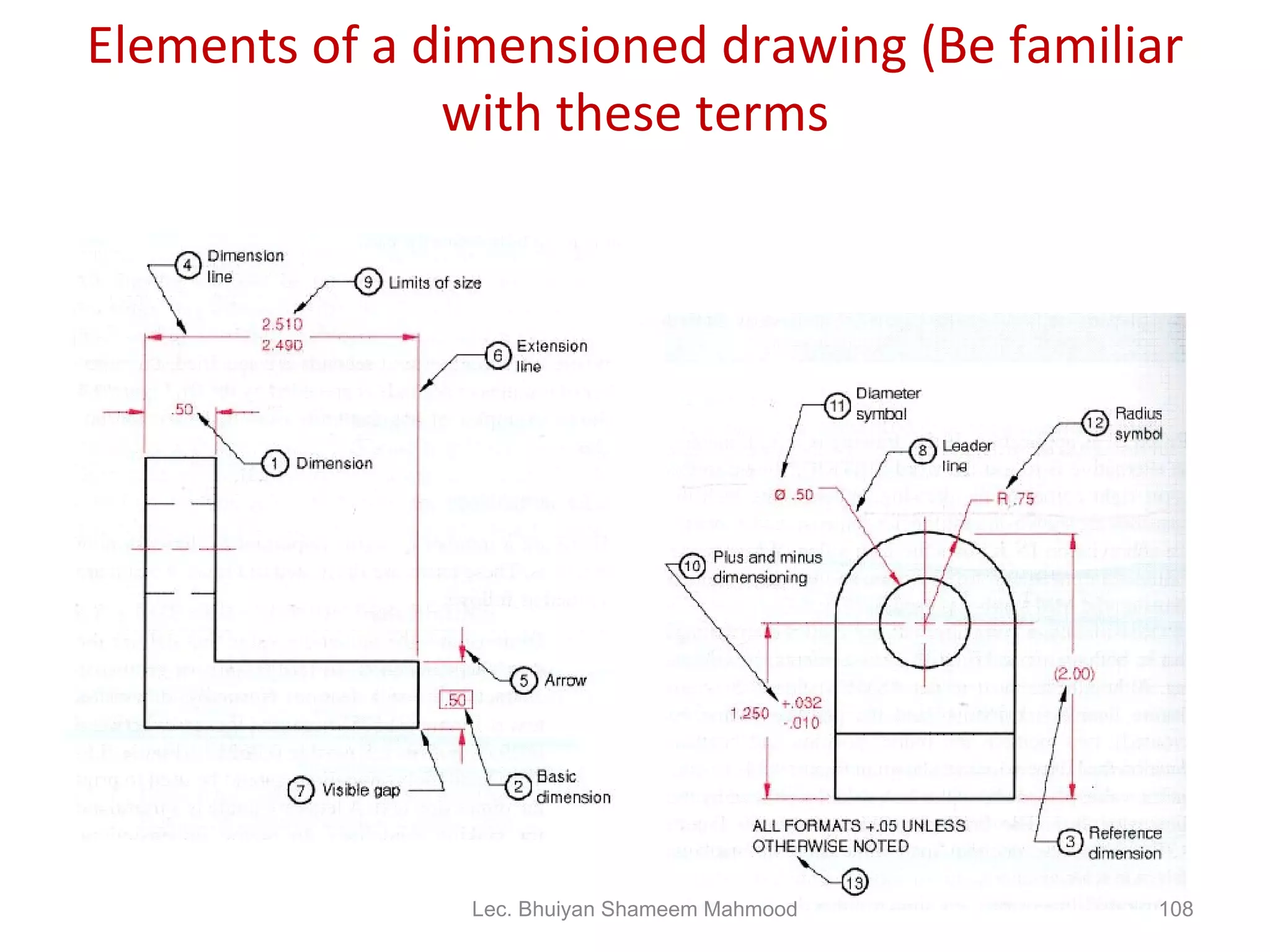

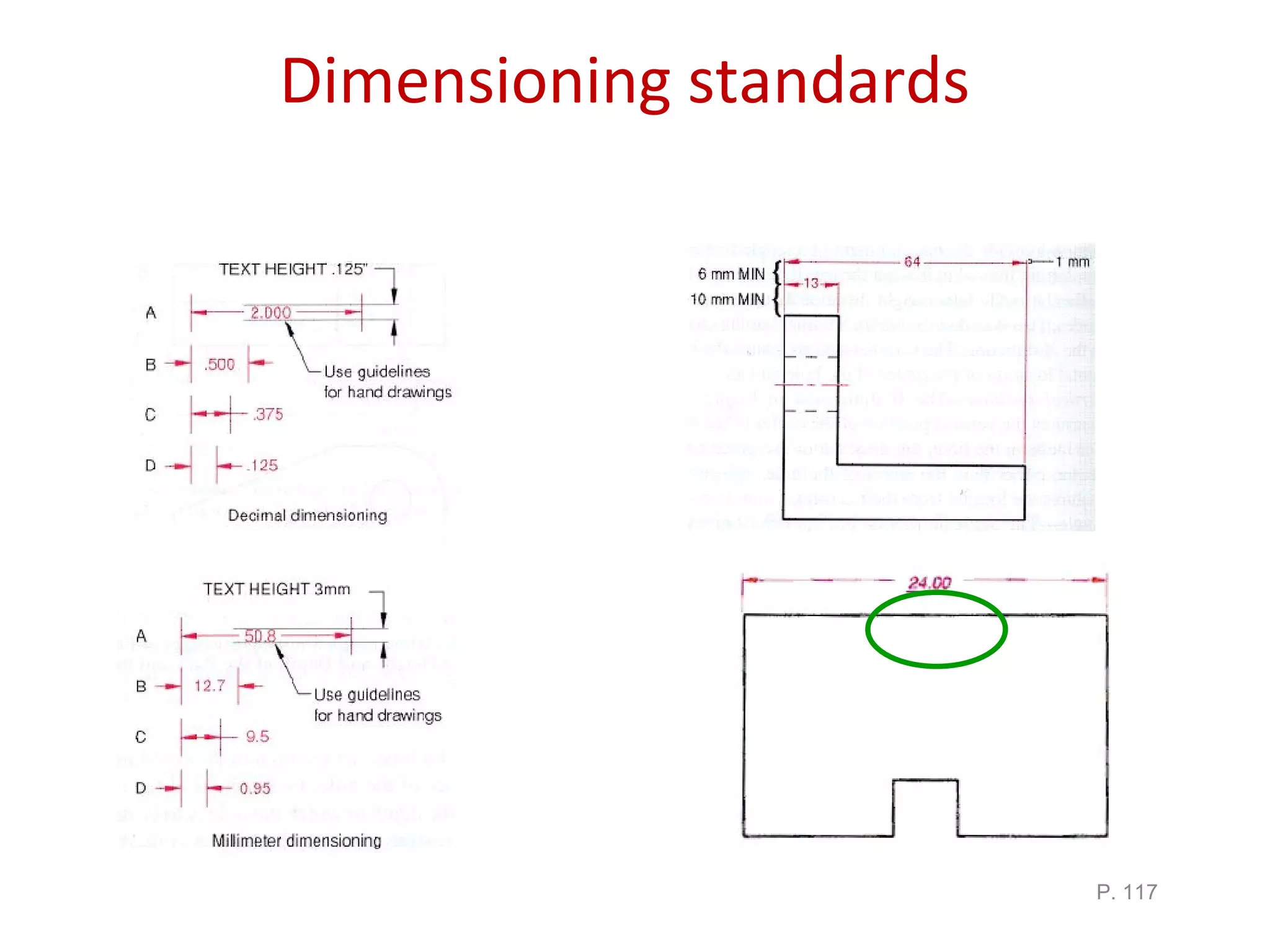

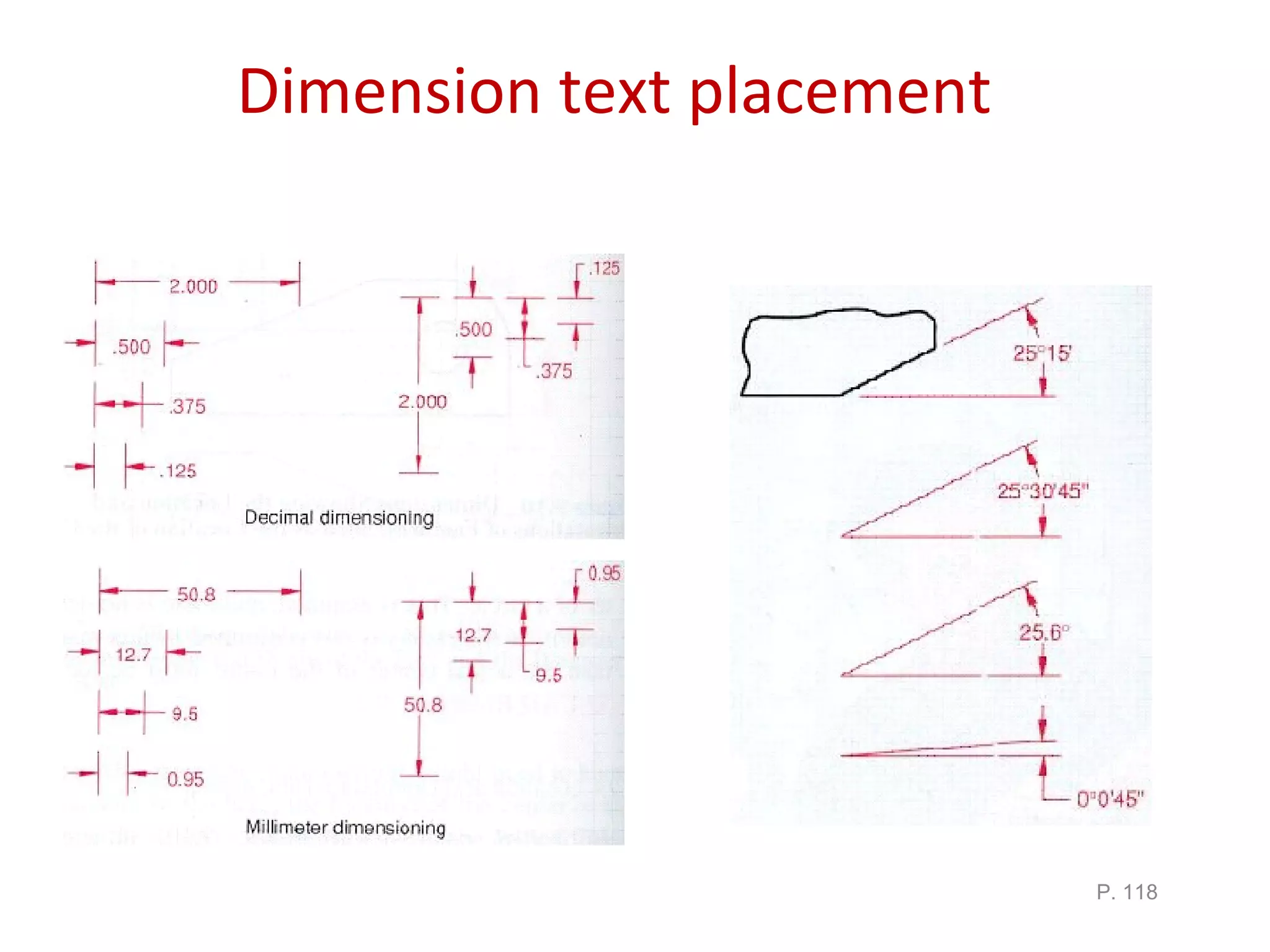

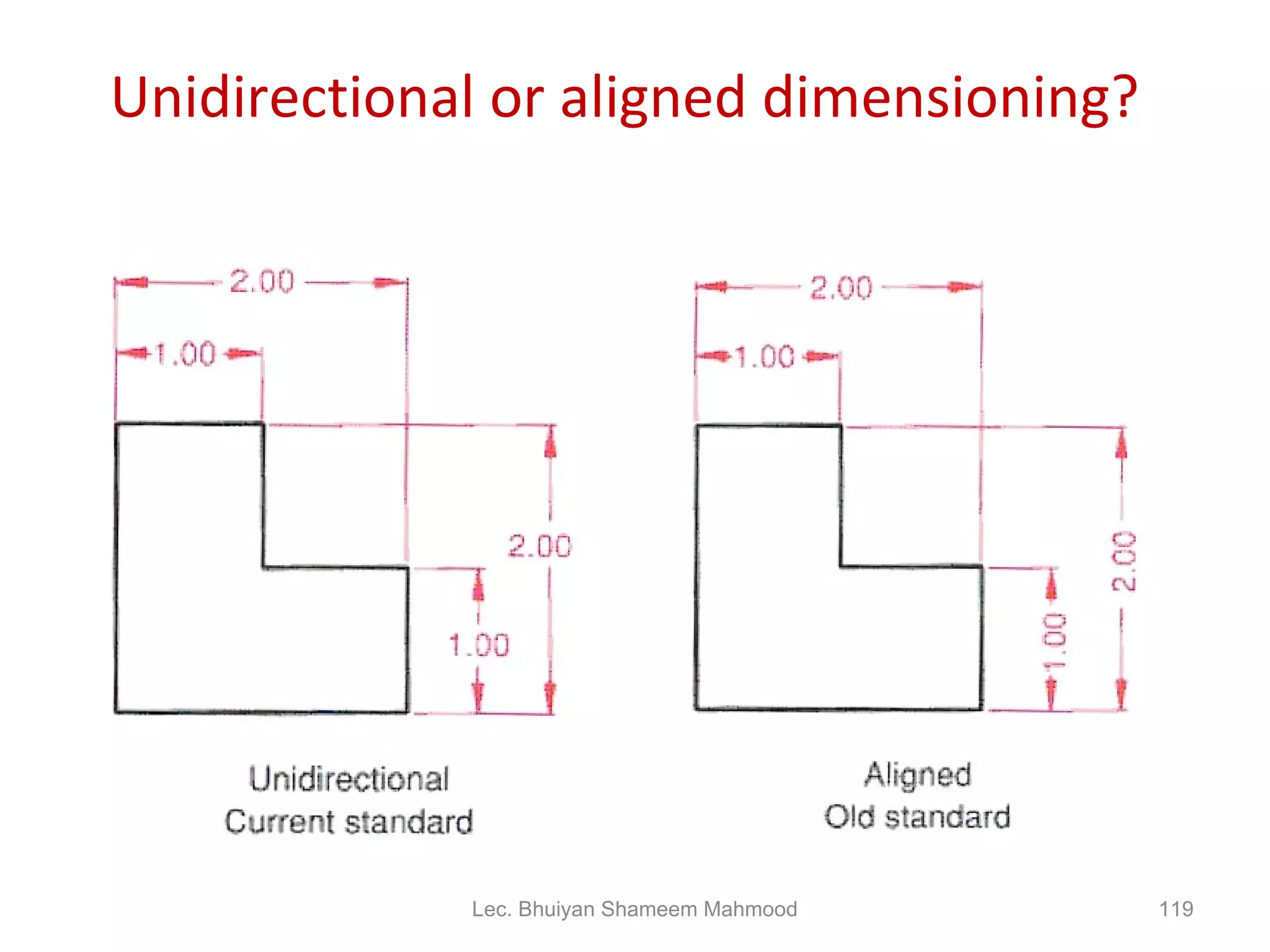

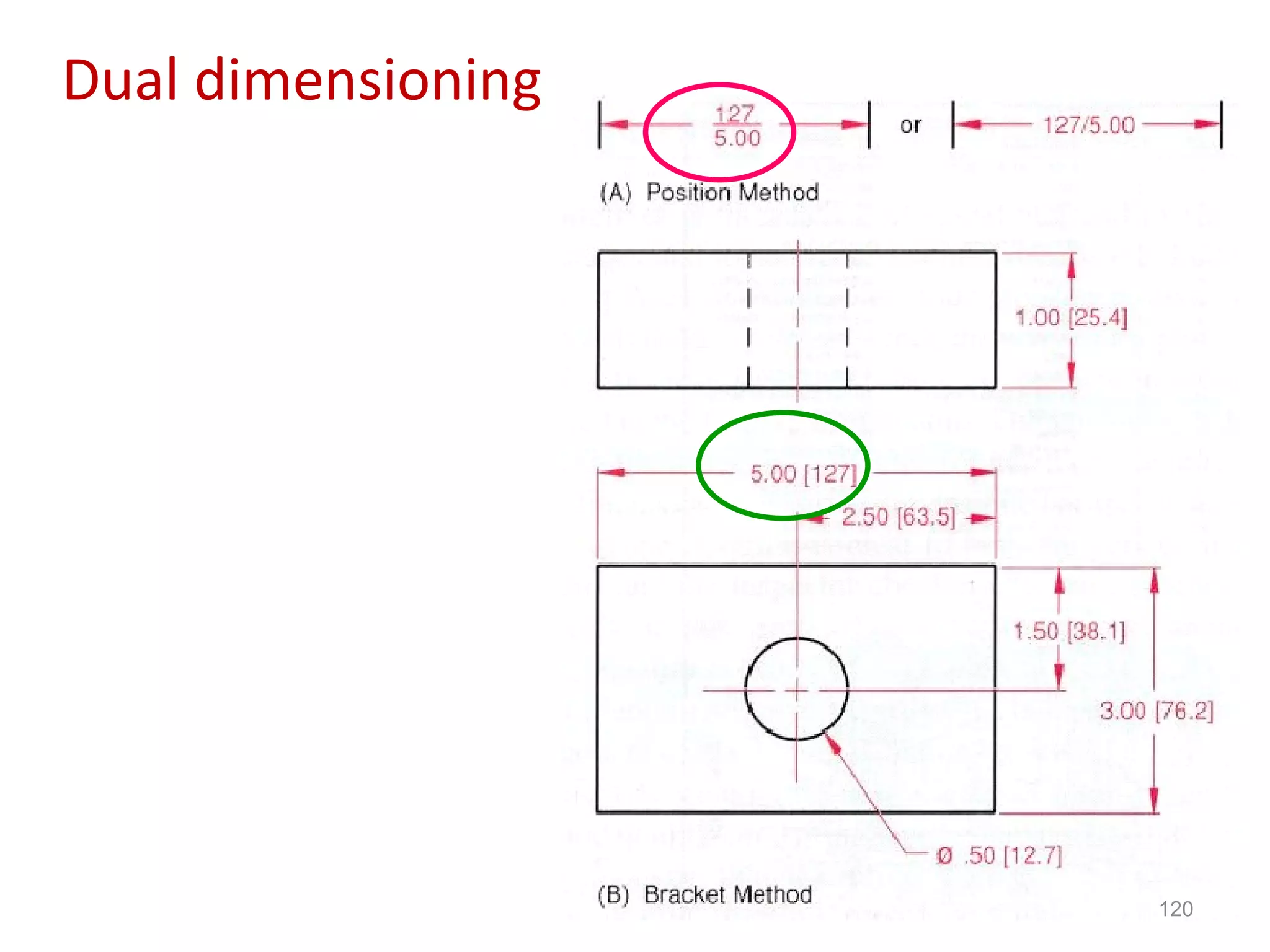

The document outlines a course on engineering drawing, covering topics such as basic concepts, instruments, projection methods, and types of drawings like orthographic and isometric views. It emphasizes the importance of standards, graphic and word language in drafting, and the necessity of using proper tools and techniques during the drawing process. Quizzes and class participation are critical for grading, and adherence to drawing standards is essential for clear communication in technical drawings.