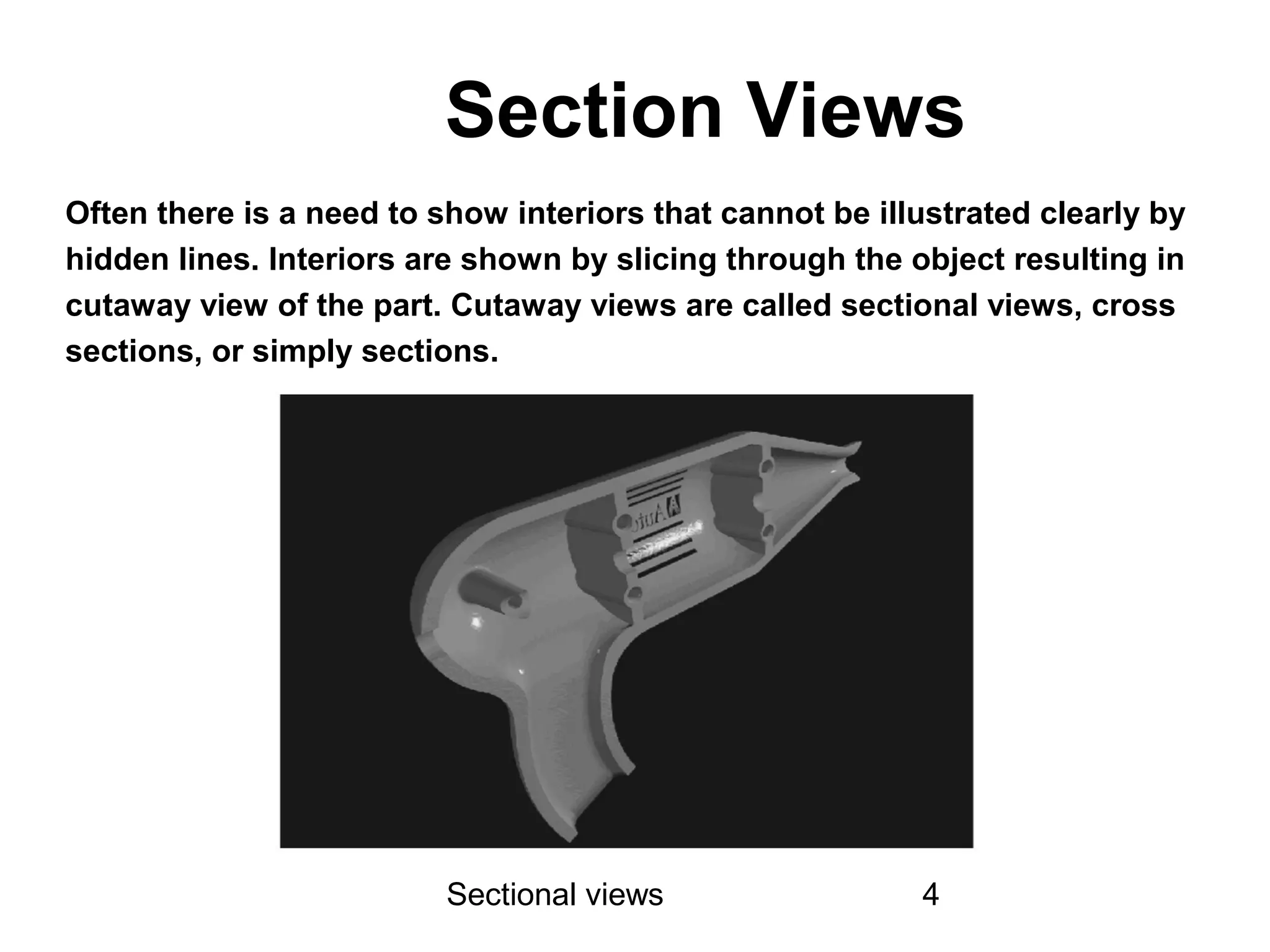

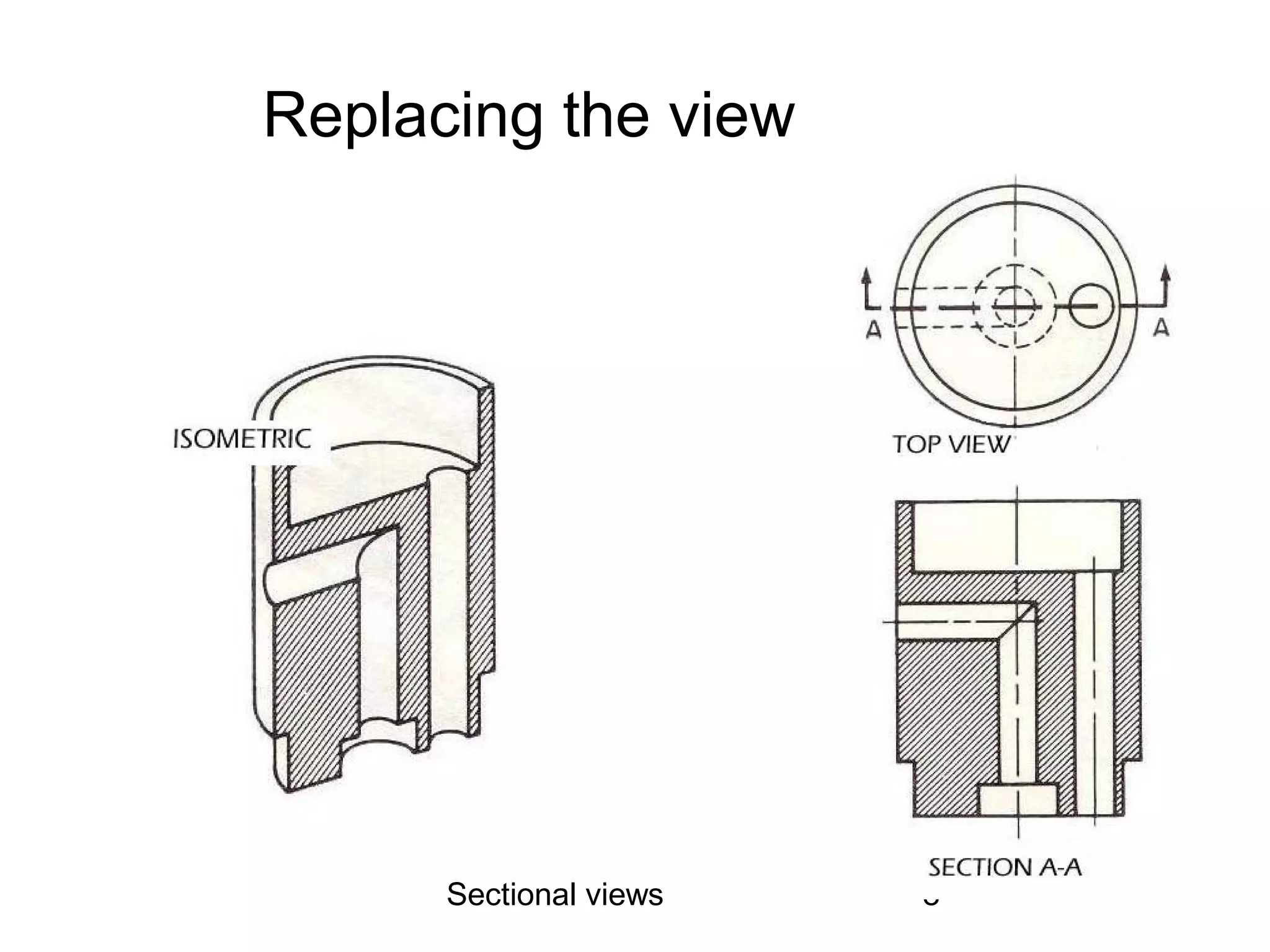

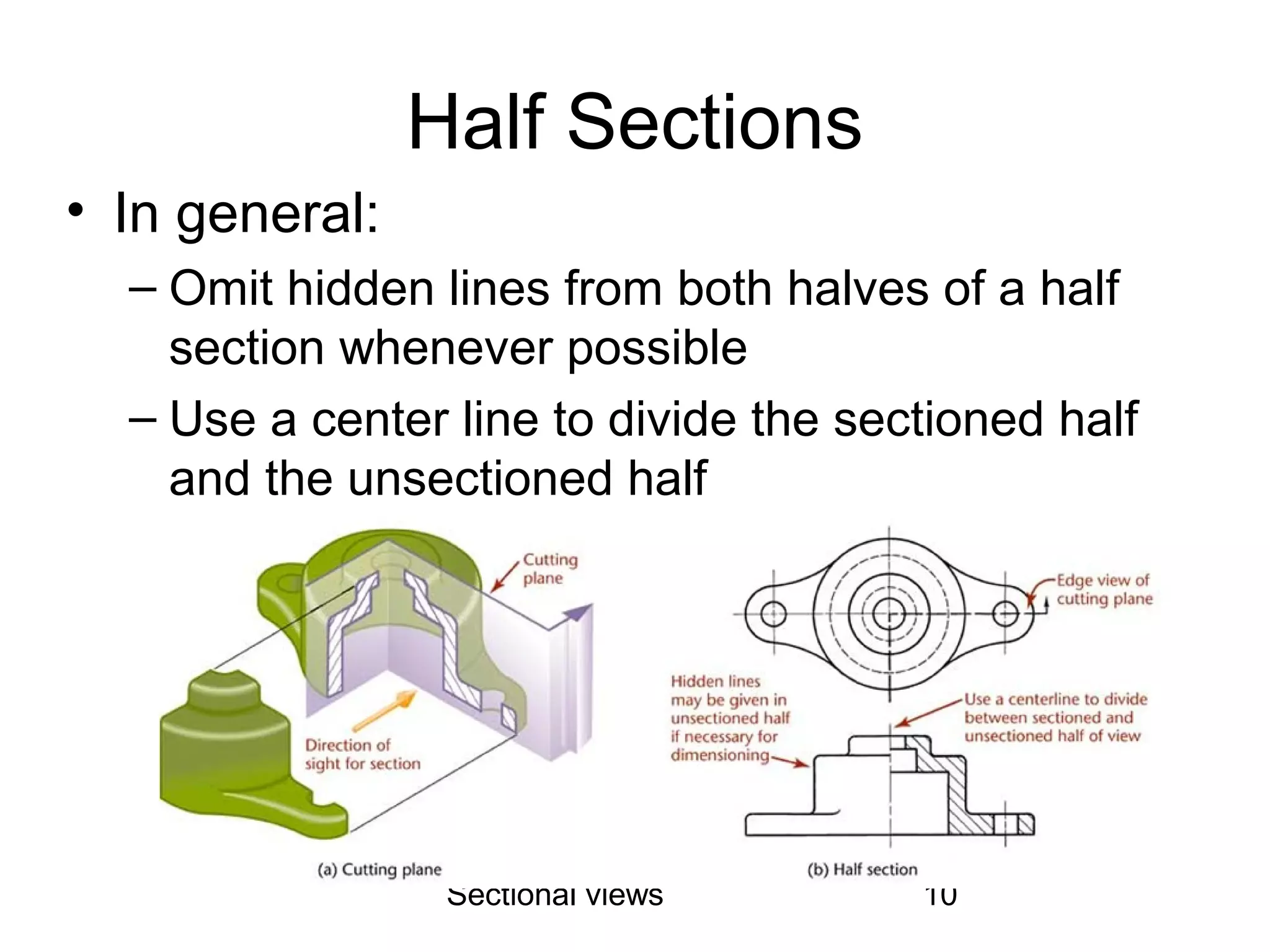

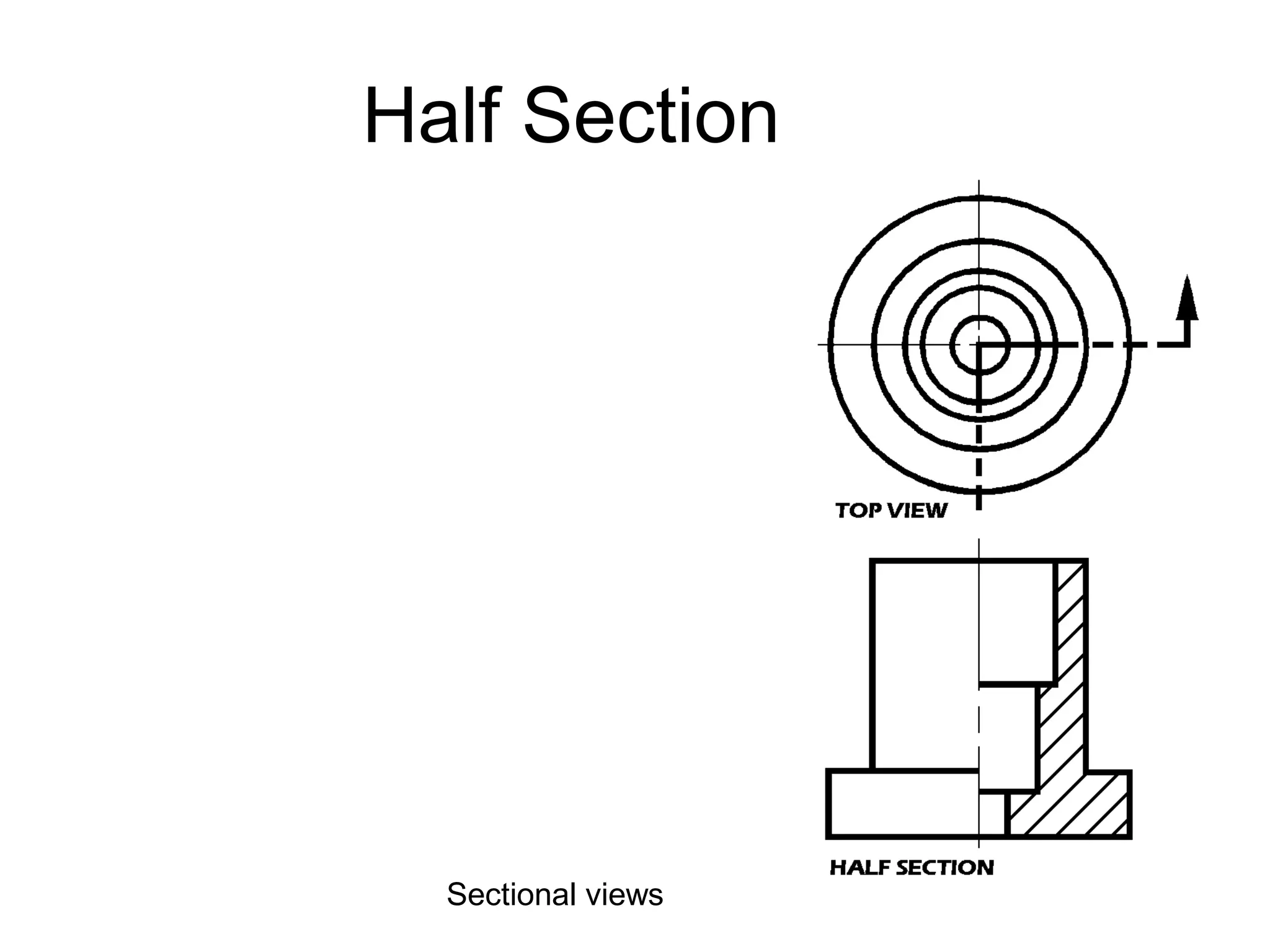

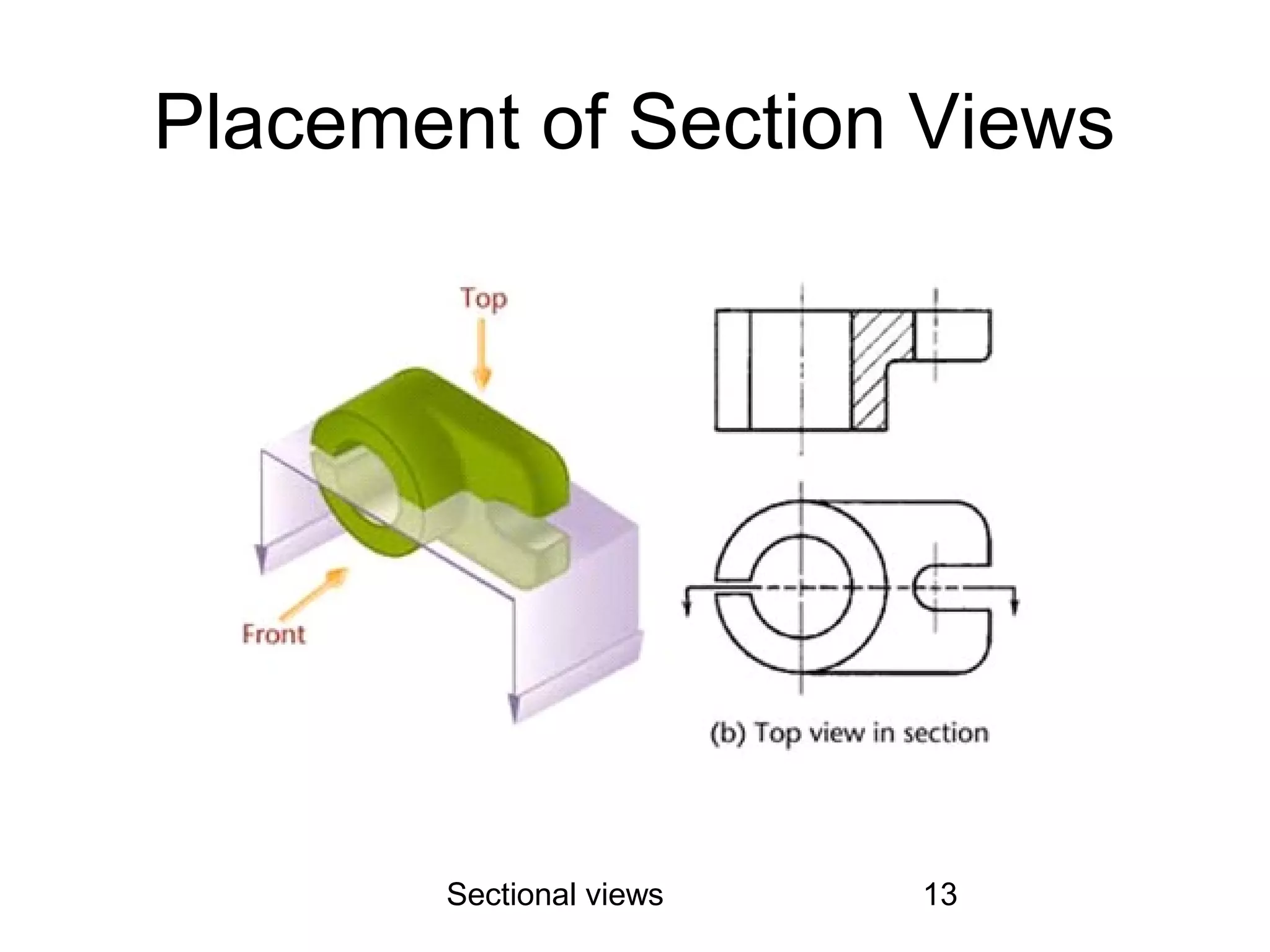

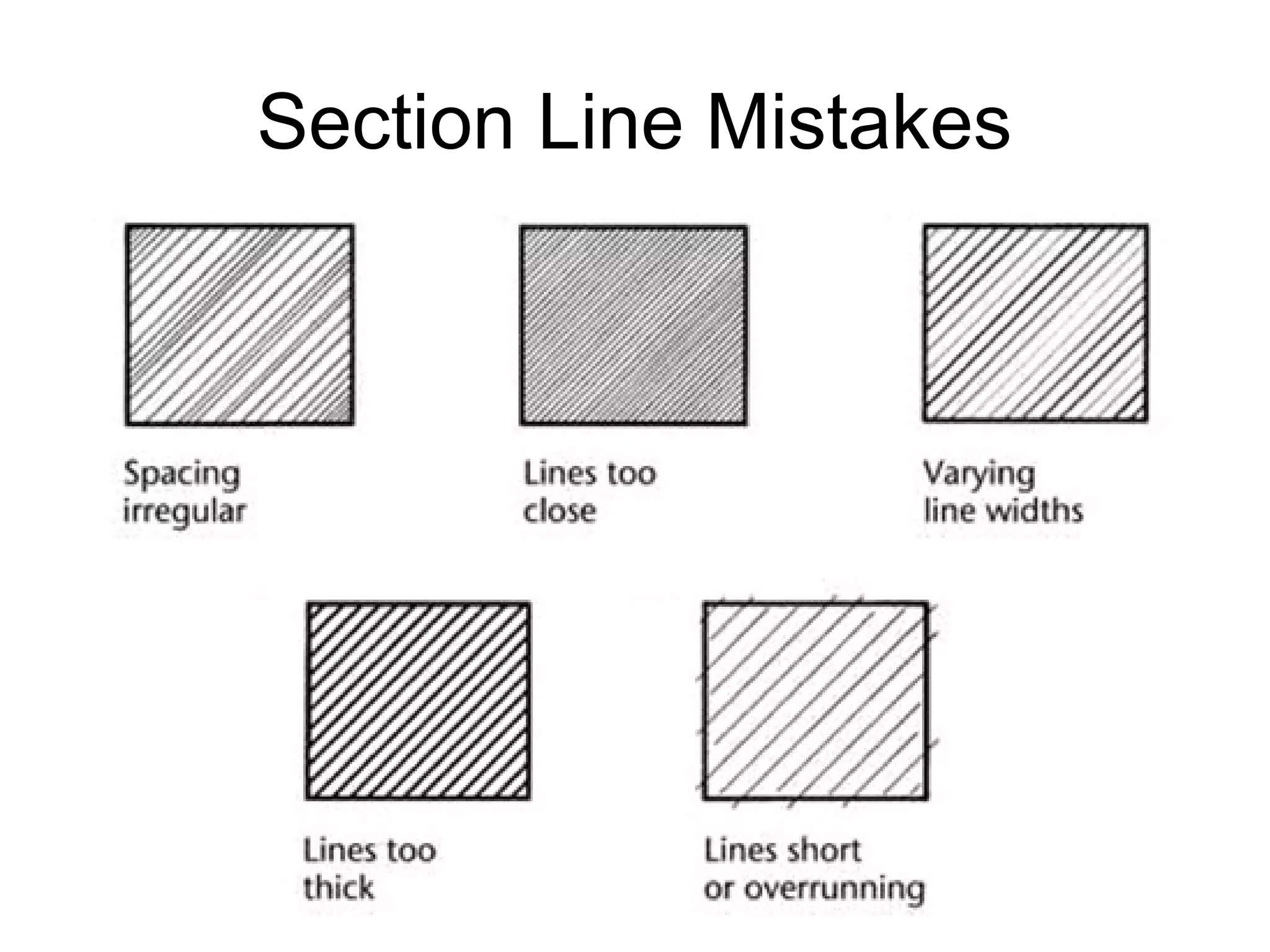

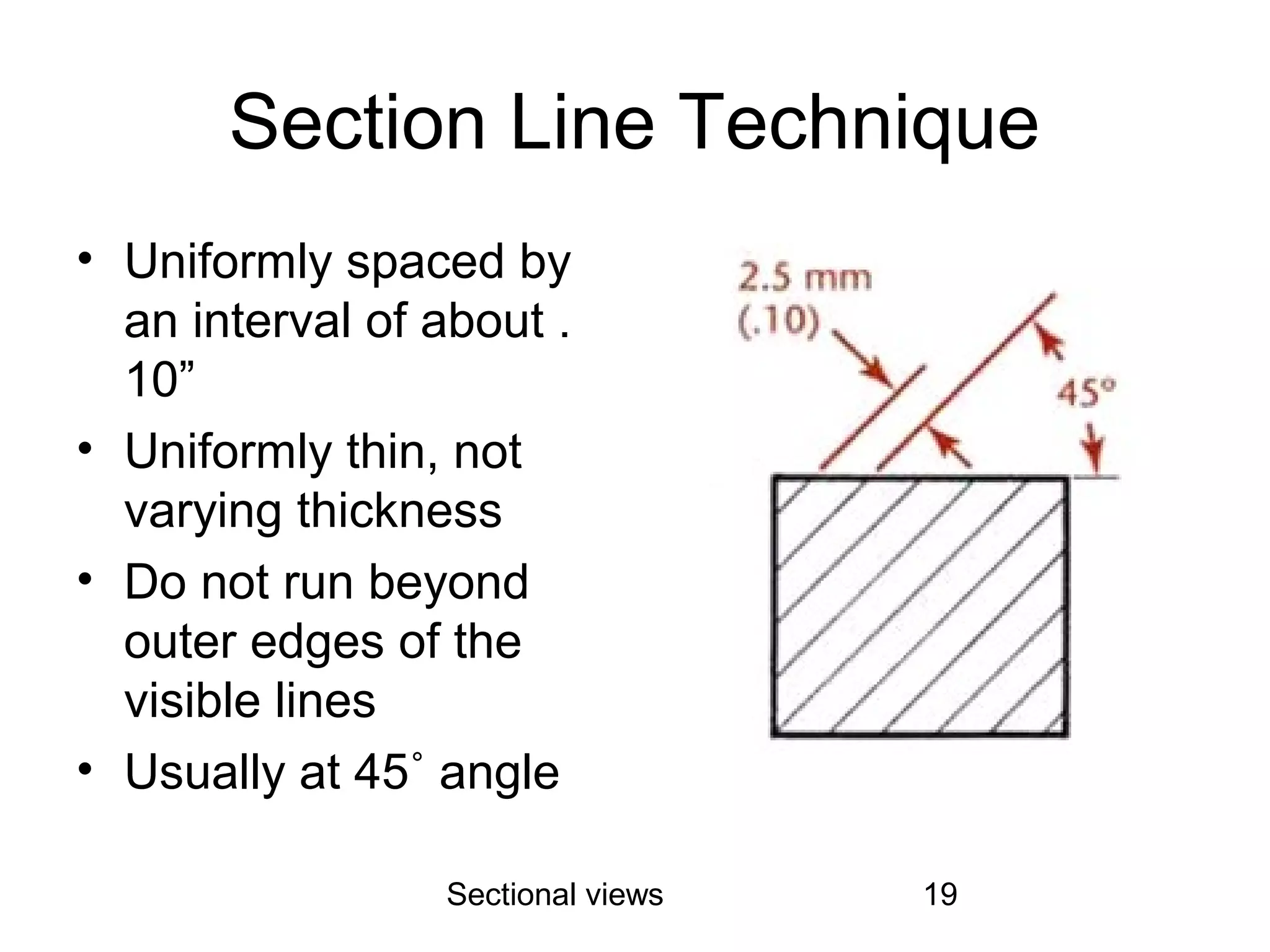

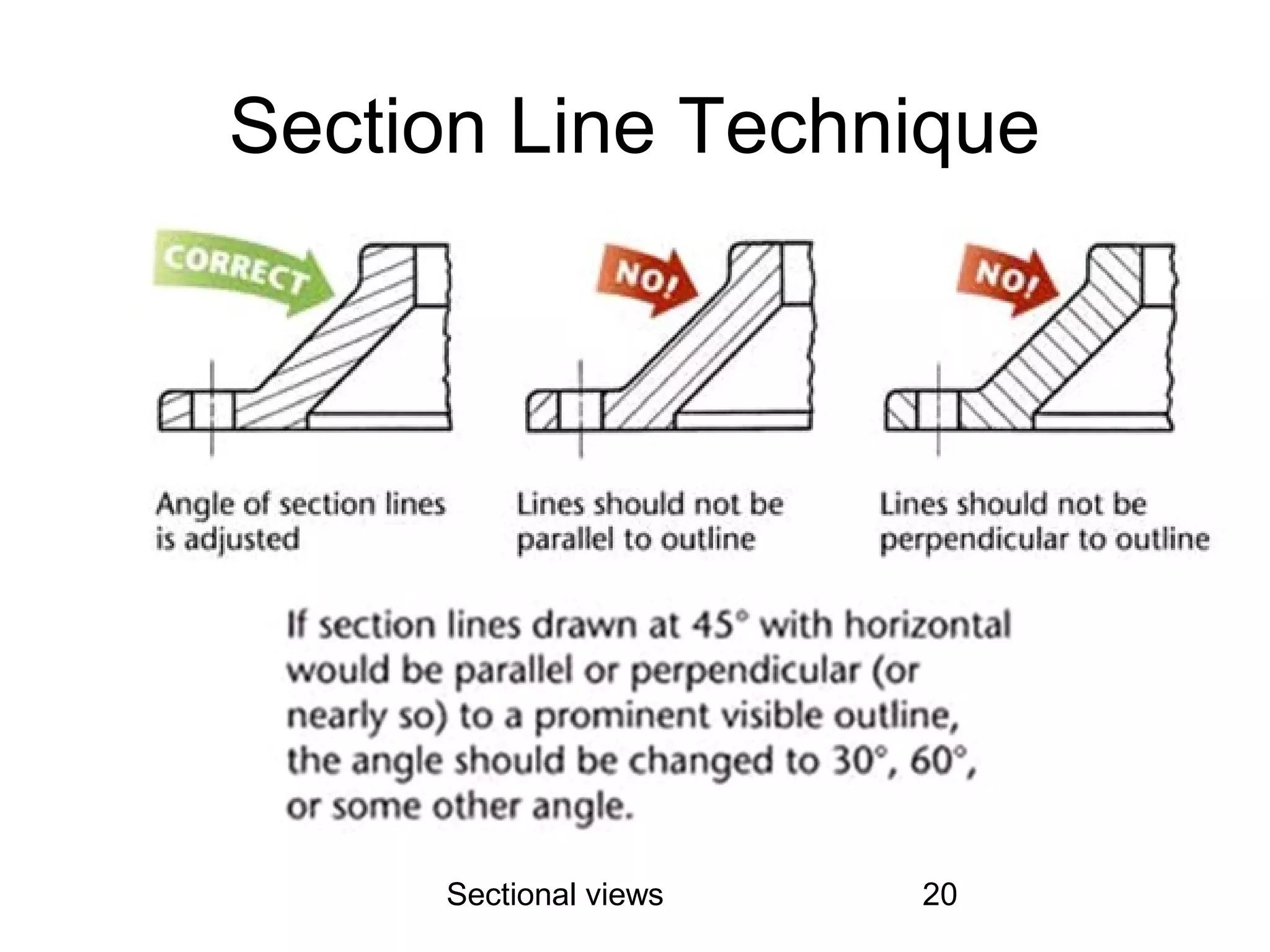

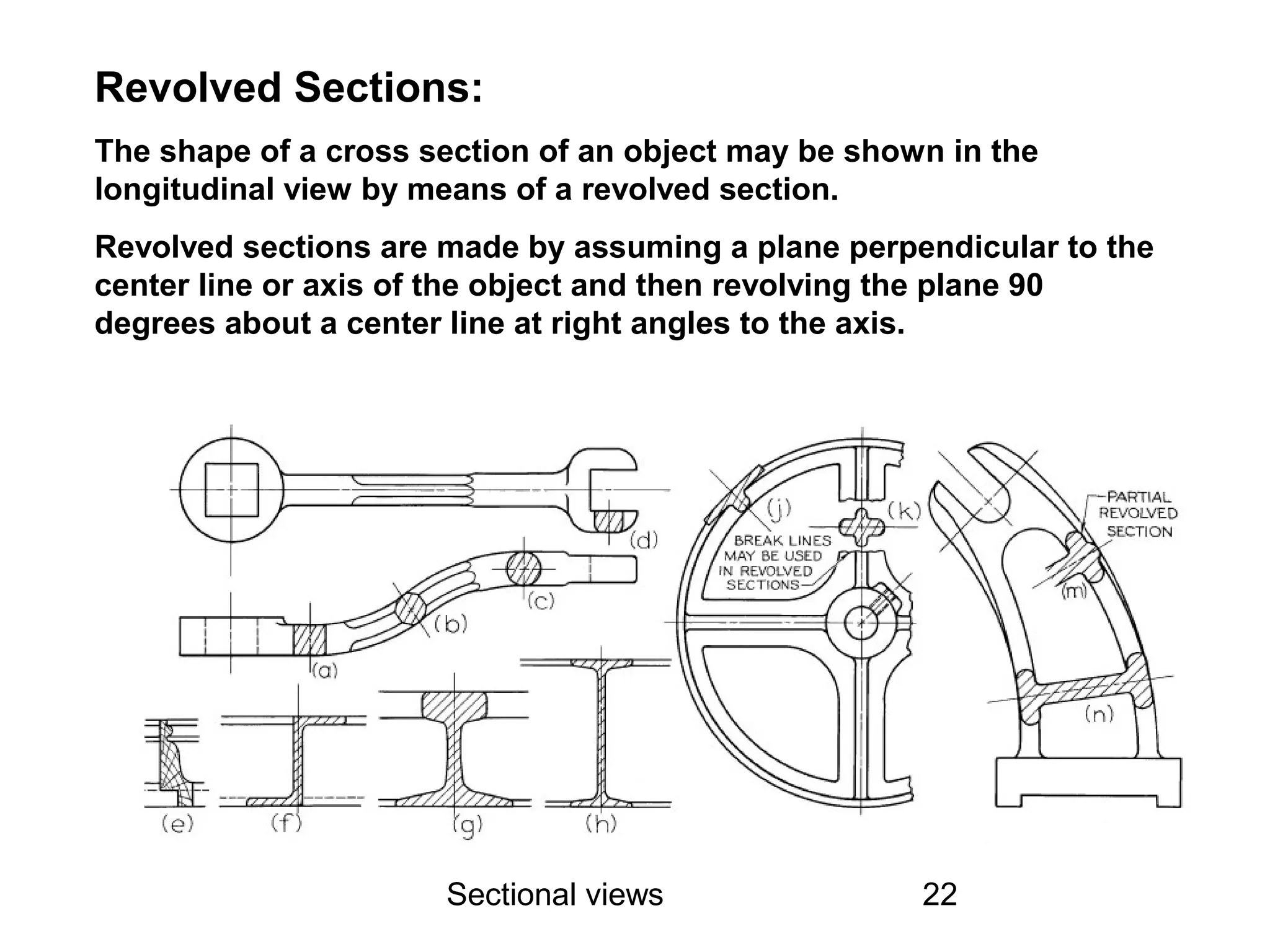

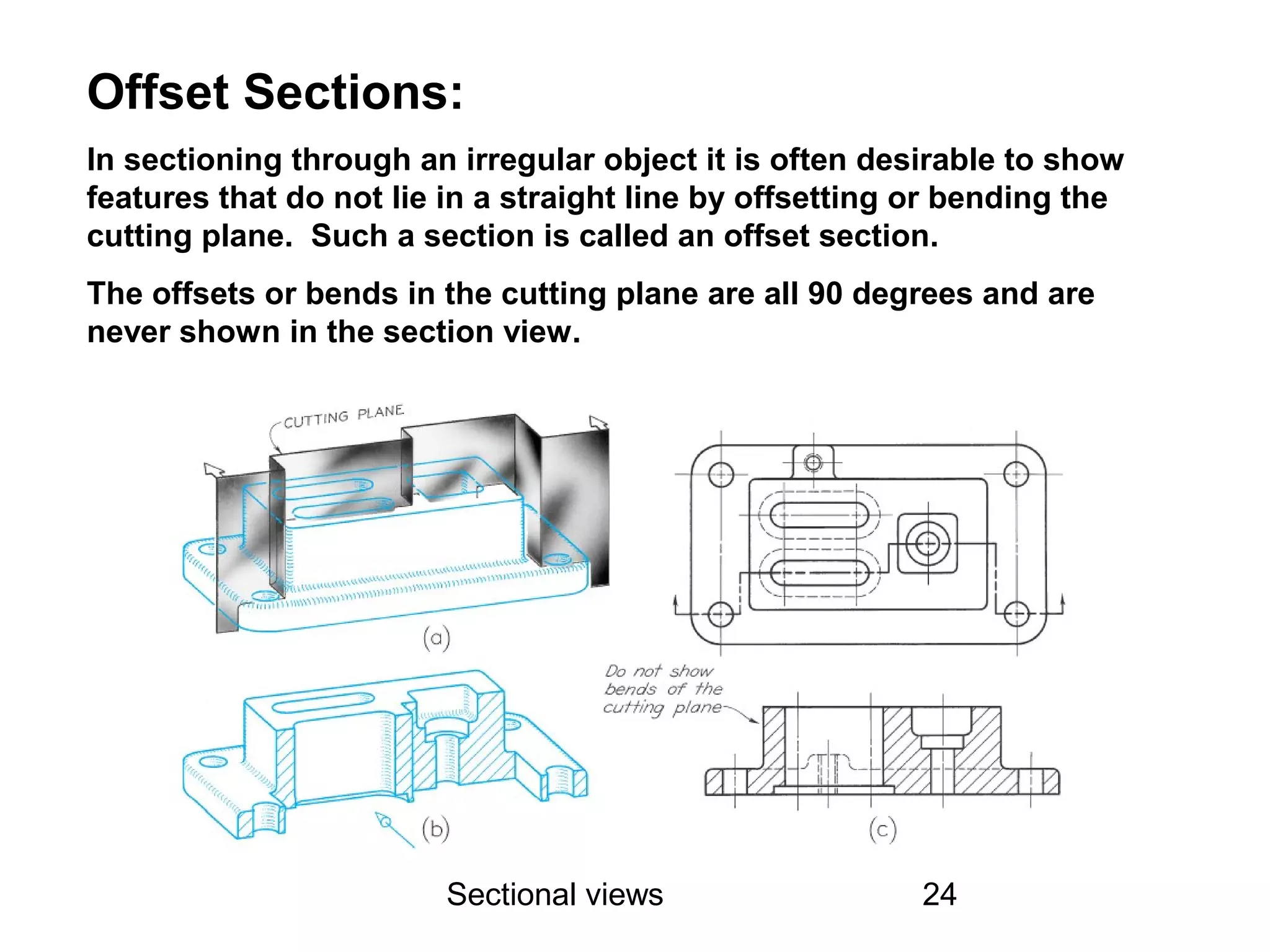

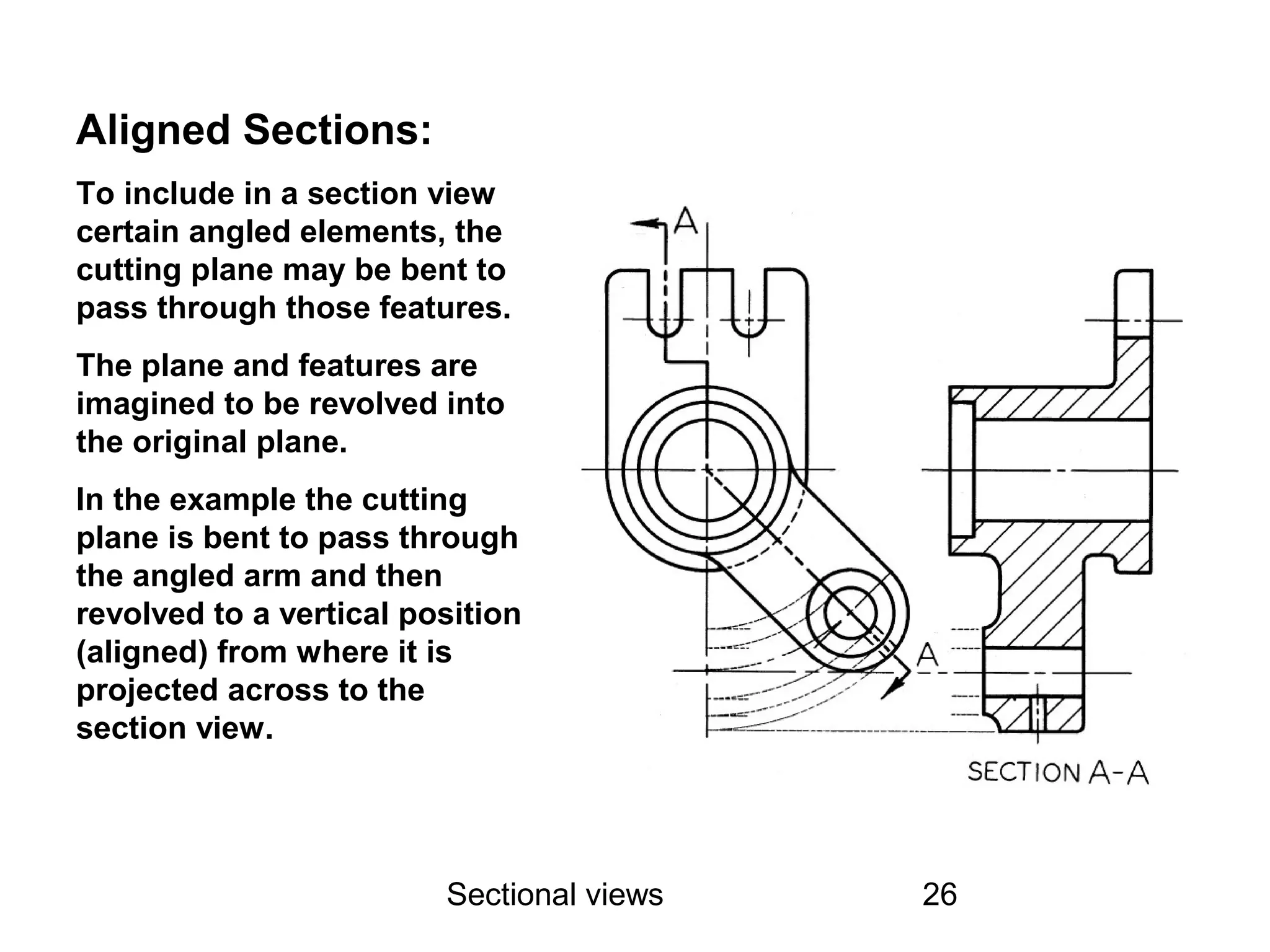

This document discusses different types of section views including full sections, half sections, broken-out sections, removed sections, and offset sections. It addresses the proper placement of cutting planes and section lines, as well as common mistakes to avoid when creating section views. The purpose of section views is to reveal interior or hidden areas of an object by removing part of the material.