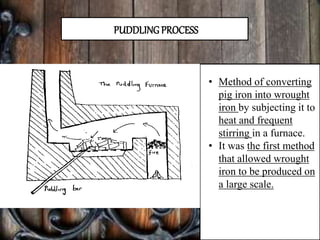

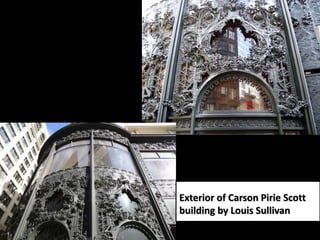

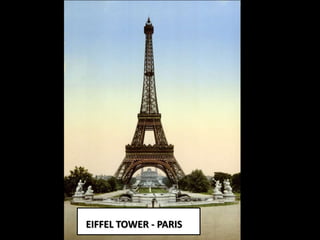

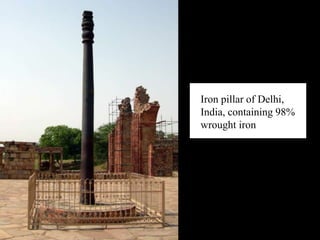

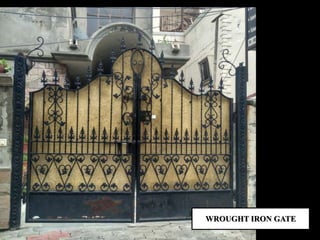

Wrought iron is a soft, ductile iron alloy containing less than 0.1% carbon. It is superior to cast iron due to its lower brittleness. Wrought iron is manufactured through puddling, which involves reheating cast iron while mixing in air to burn off carbon. It has historically been used to build structures like the Eiffel Tower and for applications such as railings and gates due to its malleability and toughness. Today, wrought iron can still be found in home decor items and architectural details.