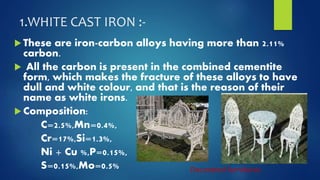

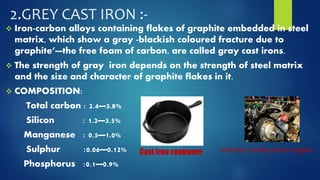

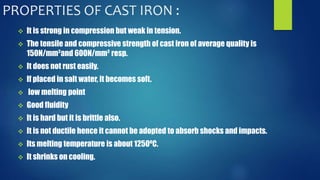

Cast iron has been used since ancient times, originating in China between 700-800 BC. It is an iron alloy containing more than 1.7% carbon. There are four main types of cast iron: white, gray, ductile, and malleable. Cast iron is strong in compression but weak in tension. It has good fluidity and machinability. Common applications include machine parts, cookware, pipes, and structural elements like columns and arches due to its strength, durability, and low cost.