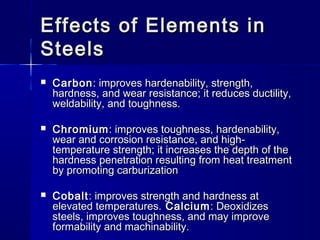

This document discusses various ferrous metals and alloys, including pig iron, cast iron, wrought iron, carbon steels, and alloy steels. It describes the production of pig iron in a blast furnace and the key properties and uses of different types of cast iron and steels. The effects of various alloying elements in steels are also summarized.

![Cast IronCast Iron

Contains 2%-4% of carbonContains 2%-4% of carbon

Very hard and brittleVery hard and brittle

Strong under compressionStrong under compression

Suitable for casting [can be pour at aSuitable for casting [can be pour at a

relatively low temperature]relatively low temperature]

Engine block, engineer vices, machineEngine block, engineer vices, machine

partsparts](https://image.slidesharecdn.com/abhippt-151016123117-lva1-app6892/85/ferrous-metals-and-alloys-8-320.jpg)