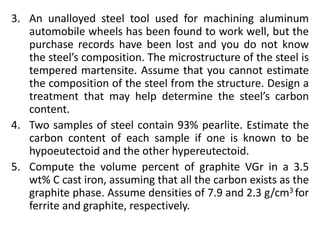

Here is a heat treatment that could help determine the carbon content of the steel:

1. Reheat the steel to above its upper critical temperature to fully austenitize it.

2. Quickly quench it in oil or water to transform the austenite to martensite.

3. Measure the hardness of the resulting martensite. Higher carbon steels will have a higher hardness.

4. Compare the measured hardness to known hardness values for different carbon contents after a similar heat treatment. This could provide an estimate of the carbon content.

The idea is that the hardness of the martensite is dependent on the carbon content. By inducing a full martensitic transformation, the carbon content