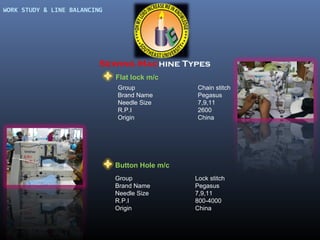

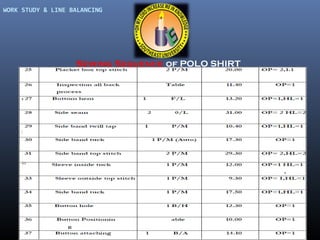

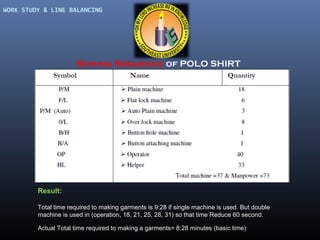

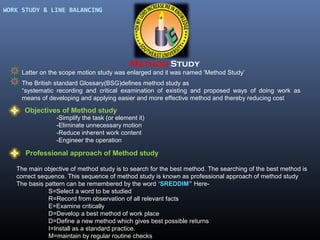

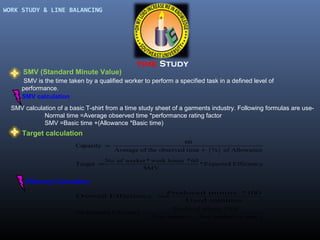

This document discusses work study and line balancing for the garments industry. It begins by introducing work study, which involves systematically analyzing work to optimize efficiency. The basic tools of work study are then outlined as work measurement, method study, and time study. Line balancing is introduced as allocating machines and work to individuals according to a work sheet to optimize production. The document then provides details on various aspects of work study and line balancing, including objectives, processes, techniques, and applications to garment manufacturing and sewing. It concludes by outlining the sewing sequence and process for making a polo shirt.