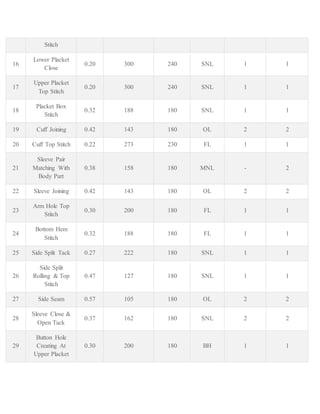

Setting up a production line for a new style requires determining the operation sequence, time, equipment, and attachments needed. Management must have this information before production starts to balance the line for maximum productivity. Standard minute values (SMVs) are calculated for each operation and combined to determine the total SMV of a garment. SMVs are established through time studies that observe cycle times, apply performance ratings, and include allowances to determine standard times for operations. SMVs are used for capacity planning, costing, performance benchmarking, and other production tasks. Industrial engineers typically calculate and validate garment SMVs.

![When an operator will be working there would be changes of a machine breakdown, they may

need to change the needle, replace empty bobbin, change thread spool, may need of threading

needle. There will be personal needs and fatigue allowance. For all these allowances, some

amount of time will be consumed from the operator’s standard time. To estimate more practical

SMV allowances are added to the basic time.

Normally, in progressive bundle system, garment components reached to an operator in bundle

form. For every bundle, the operator spends a few minutes in opening the bundle and tying it. So,

you need to add bundle allowance as well where applicable.

4. Calculate Standard minute

Add machine allowance, bundle allowance and other allowances to the basic time to calculate

standard minute.

Standard Minute Value = (Basic minute + Bundle allowances + machine allowance + personal

fatigue allowances).

Normally, when SMV is measured through time study method, the operation cycle is broken

down into operation elements and observed time is captured element-wise. Machine allowances

are added only to machine elements.

Also, note that bundle allowance is distributed across the pieces in a bundle. If bundle allowance

is 60 seconds for a 10 pieces bundle, bundle allowance would be added as 6 seconds to the basic

time.

Example: Let’s say you are making a blouse. You observed an operation and record its cycle

time. Following the above steps let’s derive SMV of an operation.

Observe Time = 2 Minutes

Rating of the operator = 90%

Basic Time = (2 Minutes x 90%) = 1.8 Minutes [Why multiply Rating factor?]

Machine allowance =10%

Other Allowance = 10%

Total allowance to add = 10% + 10% = 20%

Allowance in minutes = 1.8 x 20% = 0.36 Minutes

Calculated SMV = (1.8 Minutes + 0.36 Minutes) = 2.16 minutes

In the operation bulletin, after measuring operation SMV, hourly and daily production capacity is](https://image.slidesharecdn.com/sewinglinesetting-210812045522/85/Sewing-line-setting-3-320.jpg)