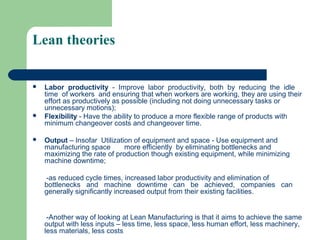

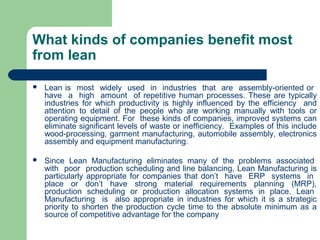

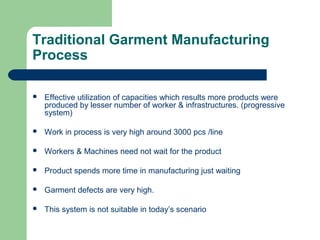

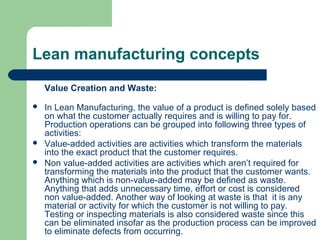

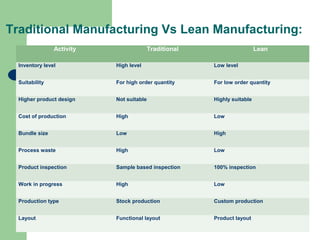

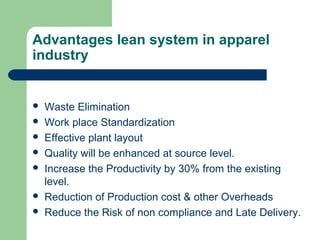

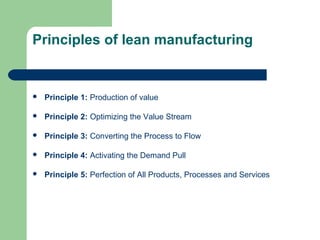

The document discusses lean manufacturing processes in the garment production industry. It defines lean manufacturing as eliminating waste to achieve the shortest possible cycle times. The goals of lean manufacturing are listed as reducing defects, cycle times, inventory levels, and costs while improving quality, productivity, flexibility and output. Key lean concepts discussed include value creation, waste elimination, just-in-time production, kanban systems, and continuous improvement (kaizen). Tools for implementing lean in apparel manufacturing include 5S, JIT, quality control charts, and standardizing processes. The benefits of lean for apparel include reduced costs, defects and lead times while improving productivity and quality.