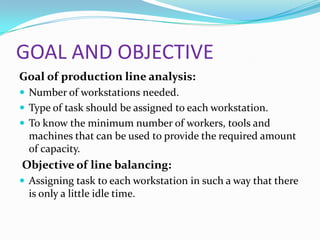

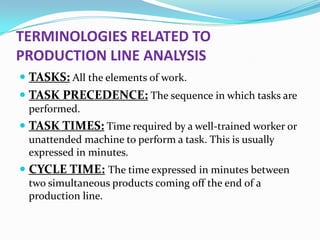

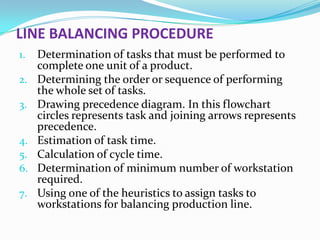

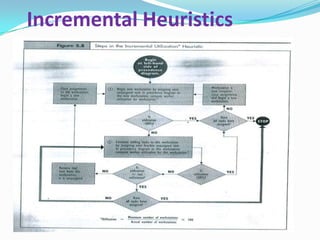

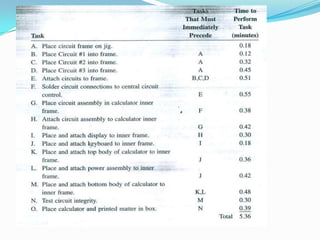

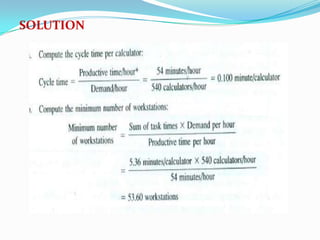

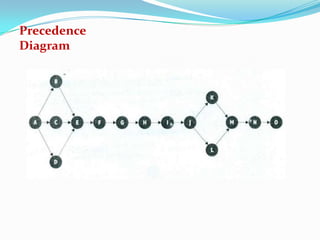

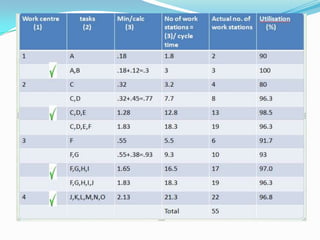

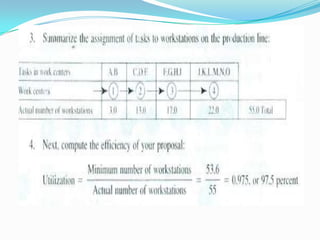

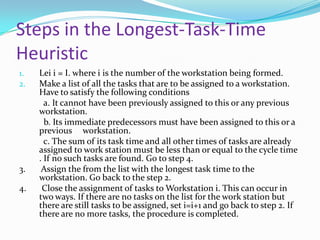

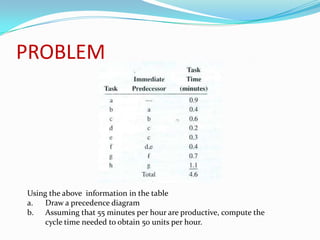

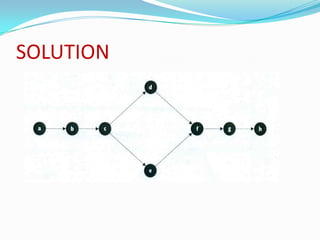

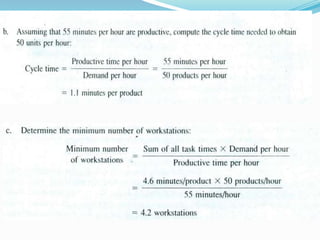

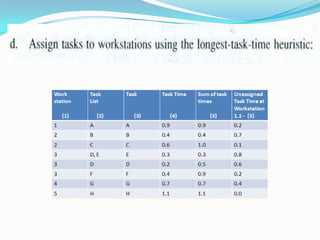

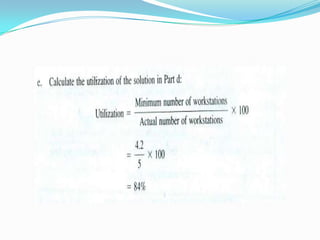

This document discusses line balancing in manufacturing, which aims to evenly divide work among workstations in a production process. The goal is to determine the optimal number of workstations, tasks assigned to each, and minimum resources needed. Key terms defined include tasks, task times, cycle time, workstations, and more. Common line balancing procedures involve determining tasks, precedence, times, cycle time, and minimum workstations. Computer programs now help balance large production lines using heuristics like incremental utilization and longest task time.