1. The document discusses improving line efficiency in a garment manufacturing plant through line balancing and layout modification.

2. It analyzes the sewing line balancing problem using the Largest Candidate Rule Algorithm and Ranked Positional Weight Method to optimally assign tasks to workstations.

3. The goal is to evenly distribute work across stations to reduce work-in-progress, waiting times, production cycle times and costs which are currently problems in the plant due to unbalanced lines.

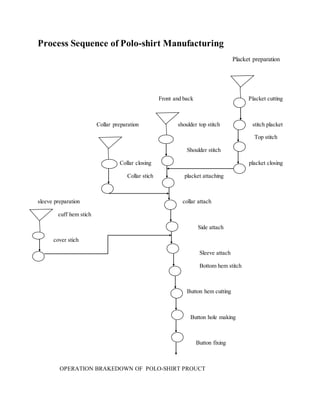

![2. Introduction

Today’s business climate for clothing manufacturers requires low inventory and quick response

systems that turn out a wide variety of products to meet customer demand. It is especially in the

apparel industry that managers are trying to develop their current systems or looking for new

production techniques in order to keep pace with the rapid changes in the fashion industry.

In apparel enterprises a raw material is processed in different departments before becoming a

garment (Figure 1). There is no doubt that the sewing department is the most important

department in the whole firm. Because there are lot of different operations which are done

manually, the sewing department has to be under constant control. Consequently, all line

balancing processes which determine the speed of an assembly line are done in this department.

But it is a big mistake not to consider the relationship of the sewing department with other

departments.

Garment industry is one of the world’s major industries and the garment industry is a substantial

one within the supply chain of textile industry. The production process of garments is separated

into four main phases: designing/clothing pattern generation, fabric cutting, sewing, and

ironing/packing. The most critical phase is the sewing phase, as it generally involves a great

number of operations [1].

Industrial Engineers are concerned with the balance of the lines by assigning the tasks to

workstations as equally as possible. Unequal workload among workstations of a sewing line will

lead to the increase of both WIP and waiting time, indicating the increase of both production

cycle time and cost

The sewing line consists of a set of workstations in which a specific task in a predefined

sequence is processed. In general, one to several tasks are grouped into one workstation. Tasks

are assigned to operators depending on the constraints of different labor skill levels. Finally,

several workstations in sequence are formed as a sewing line. Shop floor managers are

concerned about the number of workstations. Inappropriate workstations assignment will leads to

the increase of labor cost, WIP, cycle time and poor throughput. These shop floor supervisors

arrange tasks to workstations based on their experience in practice. As a result, the line balance

performance cannot be guaranteed from one supervisor to another with different assignment

preference and/or work experience [2].

In manual-operations oriented system of garment manufacturing, there are different operations,

which are done manually. If the operation manager needs to develop a new system, he has to

observe the real system. However, closely observing the real garment manufacturing system is

difficult and expensive [4,5].](https://image.slidesharecdn.com/lioularticle-170831144252/85/line-balancing-in-garment-industry-3-320.jpg)

![3. Statement of the Problem

In the knit wear garment plant, the raw materials are processed in different departments and finally the

product shipped to the customers. Sewing department is the large and most important section in the

garment plant and the speed of the assembly process of the components would be under strong control.

The model proposed here is based on a reconfigurable production line to meet customer requirements as

well as improve system performances. In garment industry, any garment manufacturer tries the best to

finish the assembly work soon to increase on-time delivery to reduce production cost. Assembly line

balancing is therefore a critical issue for the efficiency and competitiveness. The main problem in asbem

garment industry is there is a working progress or delay of work due to line balancing problem and there

is no equal distribution of work in production line.

4. Literature review

Line Balancing means balancing the production line, or any assembly line. The main objective of

line balancing is to distribute the task evenly over the work station so that idle time of man of

machine can be minimized. Line balancing aims at grouping the facilities or workers in an

efficient pattern in order to obtain an optimum or most efficient balance of the capacities and

flows of the production or assembly processes. Assembly Line Balancing (ALB) is the term

commonly used to refer to the decision process of assigning tasks to workstations in a serial

production system. The task consists of elemental operations required to convert raw material in

to finished goods. Line Balancing is a classic Operations Research optimization technique which

has significant industrial importance in lean system. The concept of mass production essentially

involves the Line Balancing in assembly of identical or interchangeable parts or components into

the final product in various stages at different workstations. With the improvement in

knowledge, the refinement in the application of line balancing procedure is also a must. Task

allocation of each worker was achieved by assembly line balancing to increase an assembly

efficiency and productivity. Shop floor managers are concerned with the balance of the lines by

assigning the tasks to workstations as equally as possible. Unequal workload among

workstations of a sewing line will lead to the increase of both WIP and waiting time, indicating

the increase of both production cycle time and cost. In practice, the sewing line managers or

production controllers use their experience to assign tasks to workstations based on the task

sequence, labor skill levels and the standard time required to complete each task. As a result, the

line balance performance cannot be guaranteed from one manager to another with different

assignment preference and/or work experience [3].

Assembly line balancing is the problem of assigning various tasks to workstations, while

optimizing one or more objectives without violating any restrictions imposed on the line. ALBP

has been an active field of research over the past decades due to its relevancy to diversified

industries such as garment, footwear and electronics. The assembly line balancing problem has

received considerable attention in the literature, and many studies have been made on this subject

since 1954. The assembly line balancing problem was first introduced by Bryton in his graduate](https://image.slidesharecdn.com/lioularticle-170831144252/85/line-balancing-in-garment-industry-4-320.jpg)

![thesis. In his study, he accepted the amount of workstations as constant, the workstation times as

equal for all stations and work tasks as moving among the workstations. The first article was

published in 1955 by Salveson. He developed a 0-1 integer programming model to solve the

problem. COMSOAL (Computer Method of Sequencing Operations for Assembly

Lines).Configurations of assembly lines for single and multiple products could be divided by

three line types, single-model, mixed-model and multi-model. Single-model assembles only one

product, and mixed-model assembles multiple products, whereas a multi-model produces a

sequence of batches with intermediate setup operations [6].

ALBP with various objectives are classified into three type.

ALBP-I: Minimizes the number of workstations, for a given cycle time.

ALBP-II: Minimizes the cycle time, for a given number of workstations.

ALBP-III: Maximizes the workload smoothness, for a given number of workstations.

Balancing assembly lines becomes one of the most important parts for an industrial

manufacturing system that should be supervised carefully. The success of achieving the goal of

production is influenced significantly by balancing assembly lines. Since then, many industries

and for sure researchers, attempt to find the best methods or techniques to keep the assembly line

balanced and then, to make it more efficient. Furthermore, this problem is known as an assembly

lines balancing problem . An assembly line consists of workstations that produce a product as it

moves successively from one workstation to the next along the line, which this line could be

straight, u-line or parallel until completed. To balance an assembly line, some methods have

been originally introduced to increase productivity and efficiency. These objectives are achieved

by reducing the amount of required manufacturing time to produce a finished product, by

reduction in number of workstations or both of them [7].

This paper solves single-model line balancing problem with real application. As a result, for

practical consideration, this paper focuses on the real case of an assembly line in garment

manufacturing.

An assembly line consists of workstations that produce a product as it moves successively from

one workstation to the next along the line, which this line could be straight, u-line or parallel

until completed. To balance an assembly line, some methods have been originally introduced to

increase productivity and efficiency. These objectives are achieved by reducing the amount of

required manufacturing time to produce a finished product, by reduction in number of

workstations or both of them [8].

The Largest Candidate, Kilbridge and Wester (column) and Ranked Positional Weights (RPW)

are different heuristic methods commonly utilized to arrange and distribute the description

element time along the workstations in the system. Each of those methods could be results in a

different type of workstations layout [9]. This study involved applying the first heuristic](https://image.slidesharecdn.com/lioularticle-170831144252/85/line-balancing-in-garment-industry-5-320.jpg)

![algorithms to study the process planning gaining a reduced production time. In this paper, largest

Candidate Rule (LCR), balancing method is selected for polo shirt Assembly Line balancing.

Balancing assembly lines becomes one of the most important parts for an industrial

manufacturing system that should be supervised carefully. The success of achieving the goal of

production is influenced significantly by balancing assembly lines. Since then, many industries

and for sure researchers, attempt to find the best methods or techniques to keep the assembly line

balanced and then, to make it more [10]

Balancing assembly lines becomes one of the most important parts for an industrial

manufacturing system that should be supervised carefully. The success of achieving the goal of

production is influenced significantly by balancing assembly lines. Since then, many industries

and for sure researchers, attempt to find the best methods or techniques to keep the assembly line

balanced and then, to make it more efficient. Furthermore, this problem is known as an assembly

lines balancing problem [11]. An assembly line consists of workstations that produce a product

as it moves successively from one workstation to the next along the line, which this line could be

straight, u-line or parallel until completed. To balance an assembly line, some methods have

been originally introduced to increase productivity and efficiency. These objectives are achieved

by reducing the amount of required manufacturing time to produce a finished product, by

reduction in number of workstations or both of them [12]](https://image.slidesharecdn.com/lioularticle-170831144252/85/line-balancing-in-garment-industry-6-320.jpg)

![Reference

[1] Yi-Jhen Lin, Chun-Ju Lin, and Tiffany Y. Chen , Assembly line balancing International Conference

on Industrial Engineering and Operations Management Bali, Indonesia, January 7 – 9, 2014

[2] Md. Niaz Morshed & Kazi Saifujjaman Palash, Assembly Line Balancing, Global Journal of

Researches in Engineering: G Industrial Engineering Volume 14 Issue 3 Version 1.0 Year 2014

[3] Naveen Kumar & Dalgobind Mahto, Assembly Line Balancing, Global Journal of Researches in

Engineering Industrial Engineering Volume 13 Issue 2 Version 1.0 Year 2013

[4] MASARU NAKAJIMA, SEI UCHIYAMA, AND YOSHITO MIURA, “LINE BALANCING OF SEWING

SYSTEMS- A SIMPLE CALCULATING METHOD TO DETERMINE THE NUMBER OF WORK STATIONS AND

CYCLE TIME”, JOURNAL OF THE TEXTILE MACHINERY SOCIETY OF JAPAN, VOL. 33, NO.4, PP. 57-62,

1980.

[5] MUCELLA G. GUNER AND CAN UNAL, “LINE BALANCING IN APPAREL INDUSTRY USING SIMULATION

TECHNIQUES”, FIBERS & TEXTILES IN EASTERN EUROPE, VOL. 16, NO.2, PP. 75-78, 2008.

[6] GHOSH, S., & GAGNON,R. J. (1989). A COMPREHENSIVE LITERATURE REVIEW AND ANALYSIS OF THE

DESIGN, BALANCING AND SCHEDULING OF ASSEMBLY SYSTEMS. INTERNAL JOURNAL OF PRODUCTION

RESEARCH, 27, 637–670.

[7] M. Z. MATONDANG AND M. I. JAMBAK (2010) “SOFT COMPUTING IN OPTIMIZING ASSEMBLY LINES

BALANCING JOURNAL OF COMPUTER SCIENCE,” 6 (2): 141-162, ISSN 1549-3636 © 2010 SCIENCE

PUBLICATIONS.

[8] N ISMAIL, G. R. ESMAEILIAN, M. HAMEDI, AND S. SULAIMAN (2011) “BALANCING OF PARALLEL

ASSEMBLY LINES WITH MIXED-MODELPRODUCT,” INTERNATIONAL CONFERENCEON MANAGEMENT AND

ARTIFICIAL INTELLIGENCE IPEDR VOL.6 IACSIT PRESS,BALI,INDONESIA PP (120-124).

[9] M.P. GROOVER, (2008), “AUTOMATION, PRODUCTION SYSTEMS, AND COMPUTER-INTEGRATED

MANUFACTURING,” 3RD EDITION,ISBN:0132070731. USA

[10] M. Z. MATONDANG AND M. I. JAMBAK (2010) “SOFT COMPUTING IN OPTIMIZING ASSEMBLY LINES

BALANCING JOURNAL OF COMPUTER SCIENCE,” 6 (2): 141-162, ISSN 1549-3636 © 2010 SCIENCE

PUBLICATIONS

[11] SOTIRIOS G. DIMITRIADIS “ASSEMBLY LINE BALANCING AND GROUP WORKING: A HEURISTIC

PROCEDUREFOR WORKERS’ GROUPS OPERATING O THESAMEPRODUCT AND WORKSTATION” COMPUTERS

& OPERATIONS RESEARCH 33, 2006, PP.2757–2774.

[12] NILS BOYSEN , MALTE FLIEDNER AND ARMIN SCHOLL , “A CLASSIFICATION OF ASSEMBLY LINE

BALANCING PROBLEMS” EUROPEAN JOURNAL OF OPERATIONAL RESEARCH 183 ,2007](https://image.slidesharecdn.com/lioularticle-170831144252/85/line-balancing-in-garment-industry-17-320.jpg)