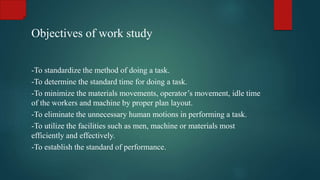

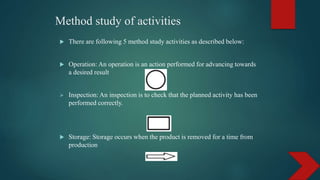

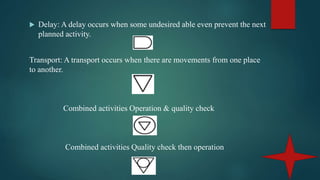

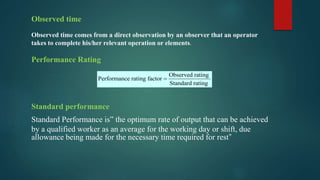

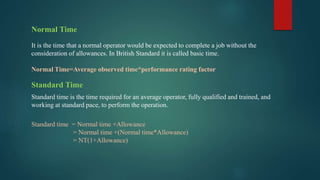

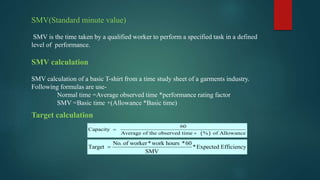

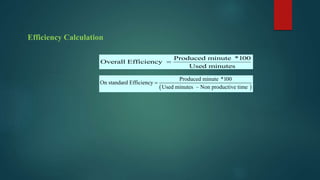

This document provides an overview of different work study techniques used in the garments industry, including work study, line balancing, method study, motion study, and time study. It discusses the objectives and processes for each technique. For example, it explains that the objective of line balancing is to minimize cycle time and maximize workload smoothness. It also provides examples of how these techniques are applied, such as describing the steps to perform a method study and calculating standard minute values from a time study.