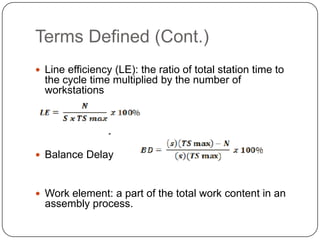

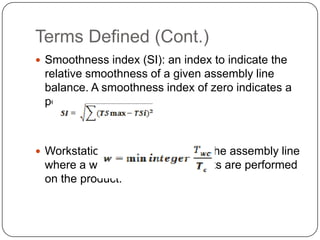

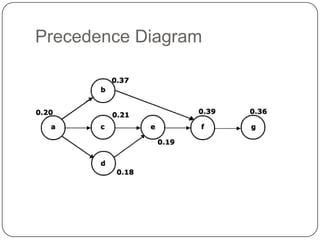

This document discusses line balancing, which involves assigning tasks along an assembly line to workstations in order to achieve minimum idle time and meet production rates. It defines key terms like cycle time, station time, line efficiency, and smoothness index. It also covers precedence constraints, which restrict the order that work elements can be completed in. Finally, it outlines several common line balancing methods, including Helgeson and Birnie's Ranked Positional Weight method, Kilbridge and Wester's region approach, and the Largest Candidate Rule.