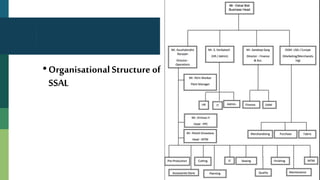

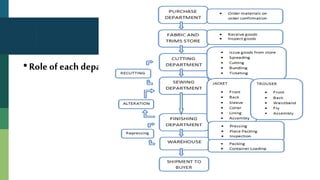

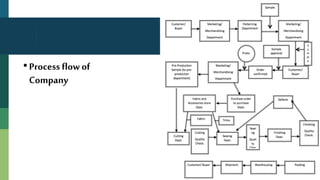

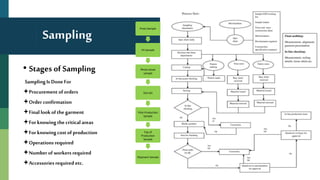

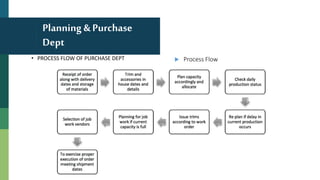

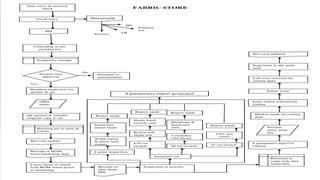

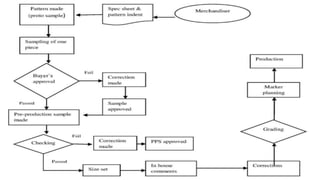

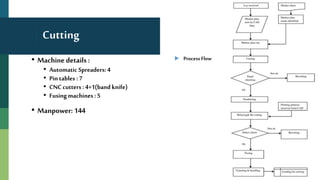

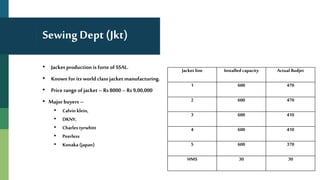

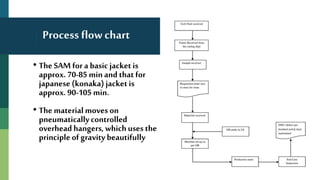

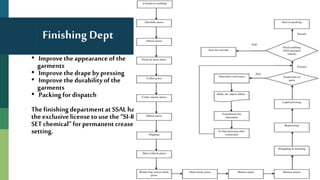

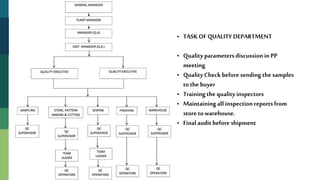

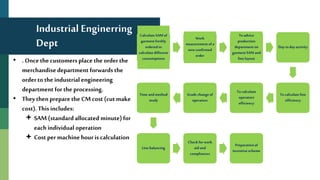

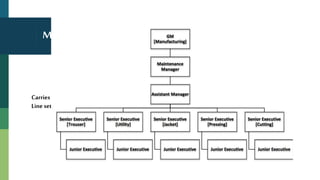

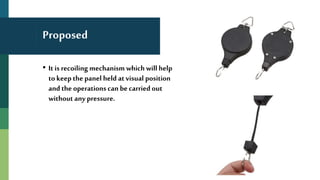

Silver Spark Apparel Ltd is a subsidiary of Raymond Limited that manufactures suits and formal trousers for export markets such as the US, Japan, Canada, and Europe. The document describes the organizational structure and processes of SSAL. It outlines the roles and process flows of key departments like planning, purchase, pre-production, cutting, sewing, finishing, and quality assurance. It also discusses sampling stages and techniques to optimize processes like workload distribution, workstation ergonomics, multi-skilling operators, tracking garment pieces, and implementing jigs and handling mechanisms.