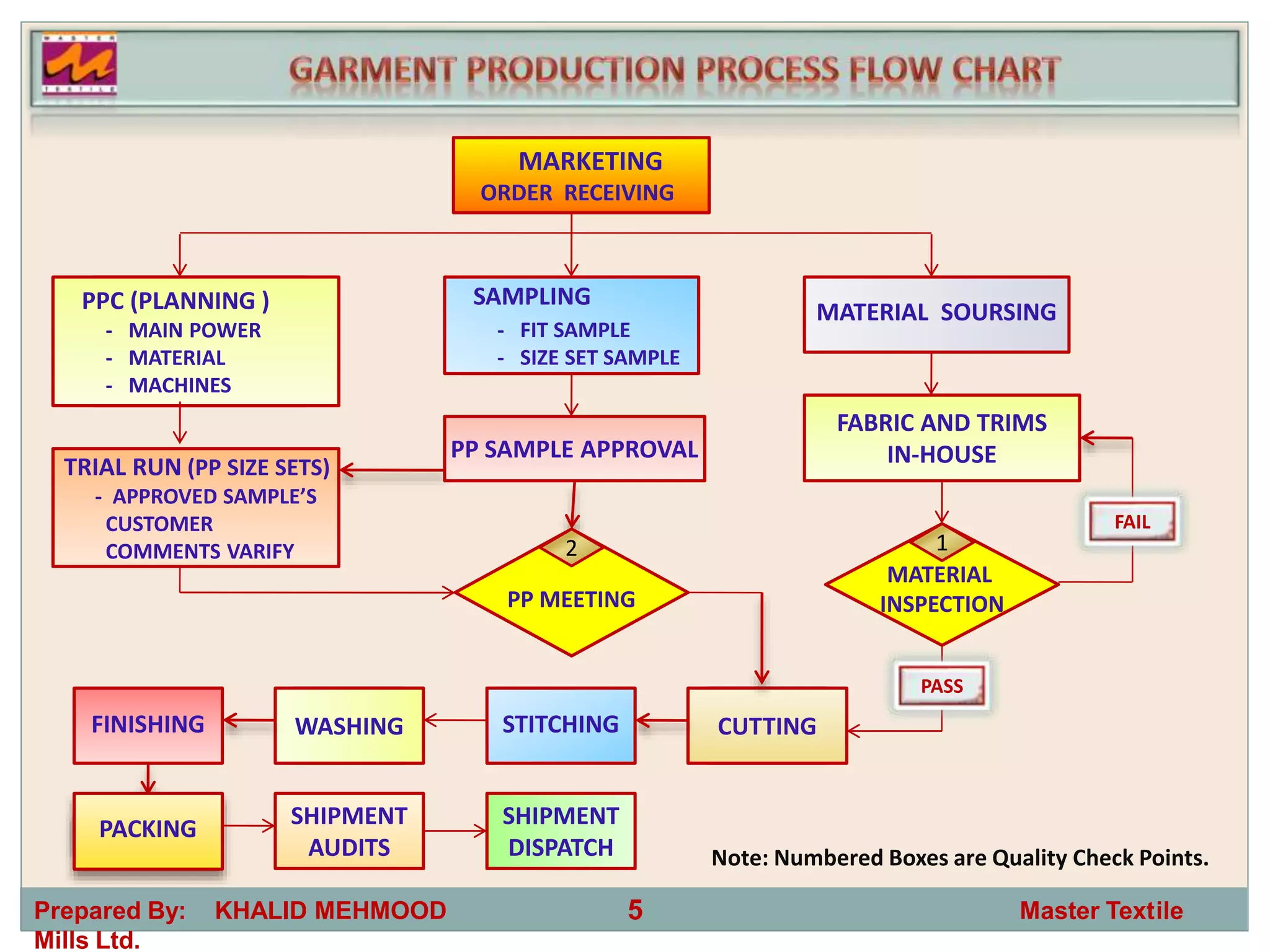

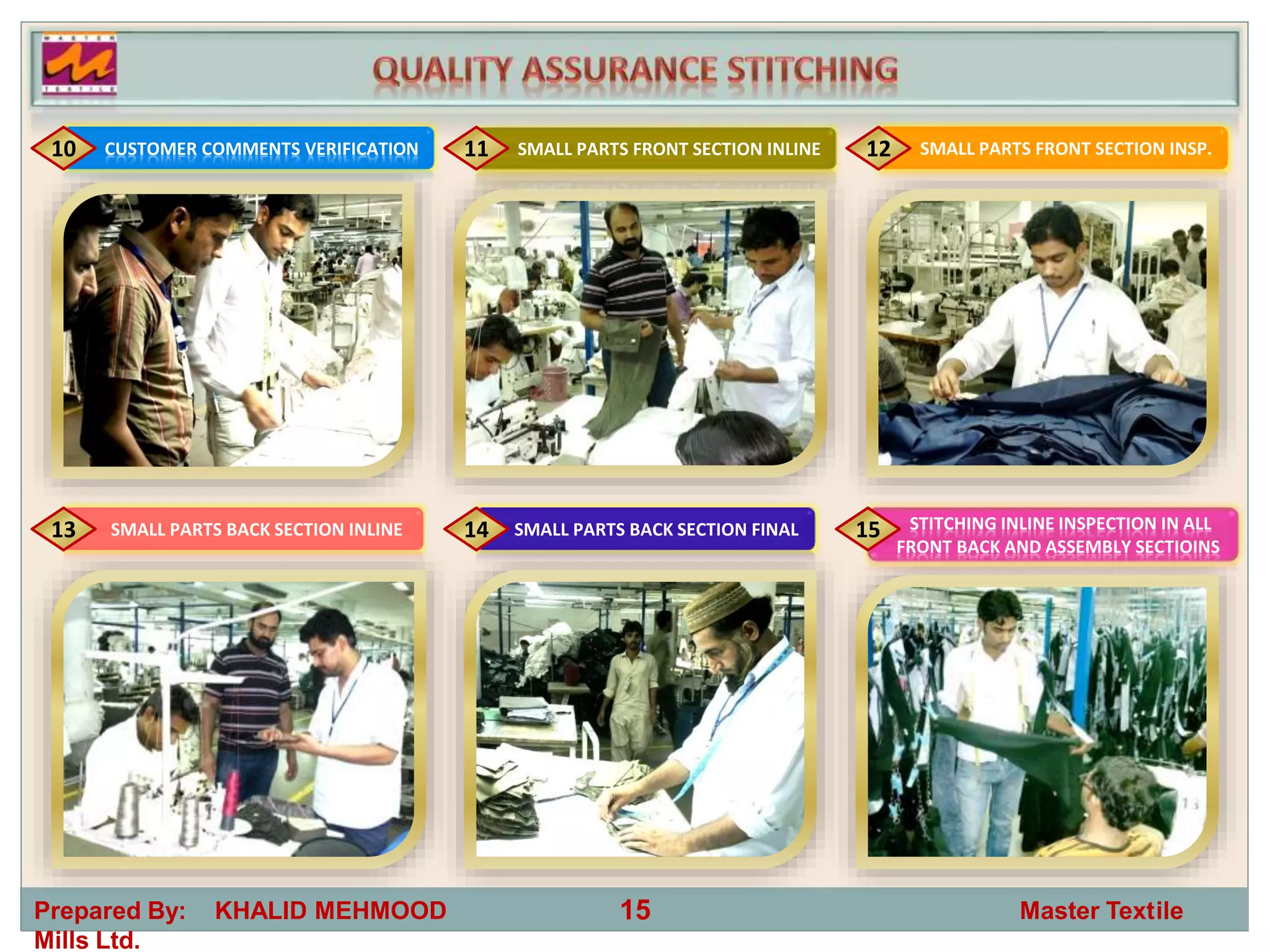

The document describes the quality assurance process in garment production. It involves inspecting fabrics and accessories at various stages of production. This includes fabric inspection, testing of materials, and checking at key points like cutting, stitching, washing, finishing, and packing. The quality assurance team aims to ensure the right product is delivered on time while meeting customer requirements and standards through continuous monitoring and improvement.