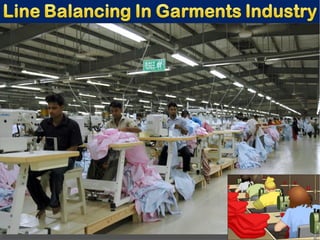

This document provides information about line balancing processes in a textile factory. It begins with an introduction to line balancing and its importance for improving production throughput and reducing costs. It then discusses various line balancing methods like time study analysis, bottleneck identification, and work allotment. Specific steps for balancing a production line are outlined, including determining operator requirements, work-in-process inventory levels, and establishing rules to ensure maximum operator capacity. Formulas for calculating standard minute values and organization efficiency are also presented.